bicycle with electric drive

A technology of electric drives and bicycles, applied in the direction of bicycle racks, bicycle accessories, bicycle gear transmission mechanisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

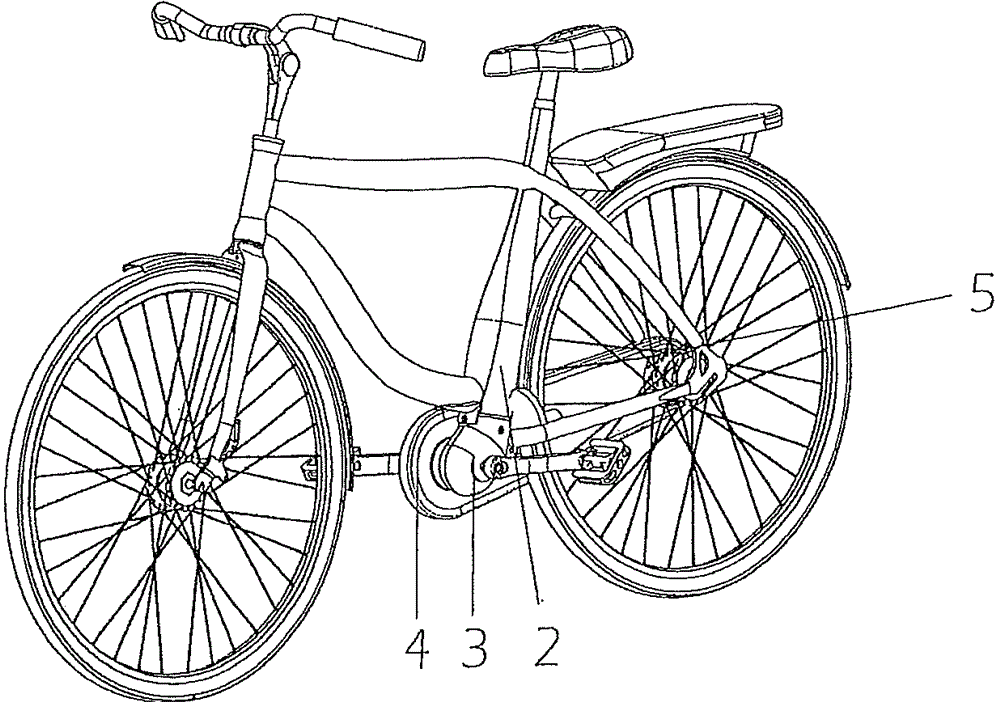

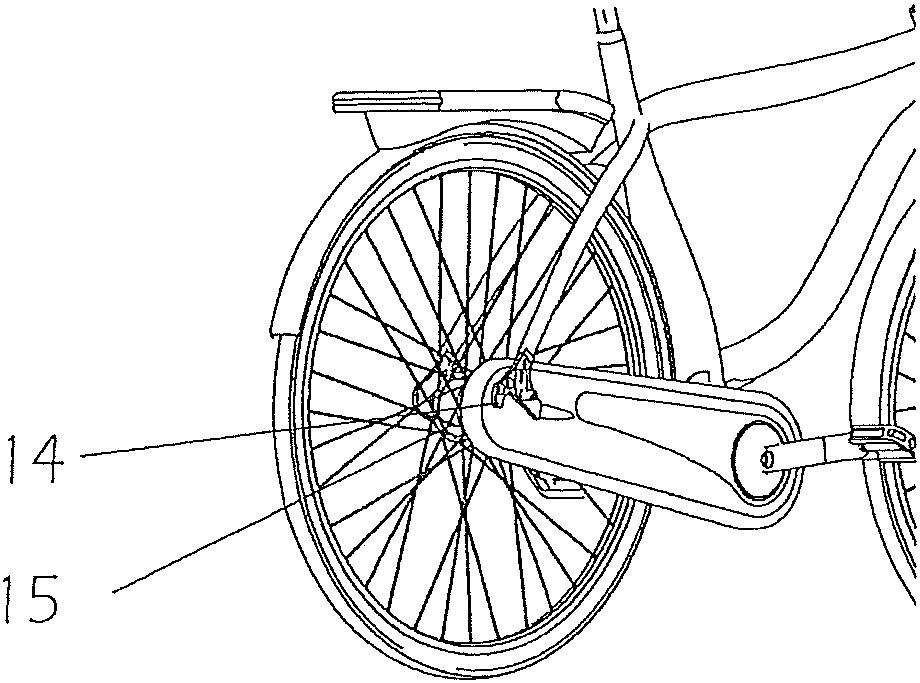

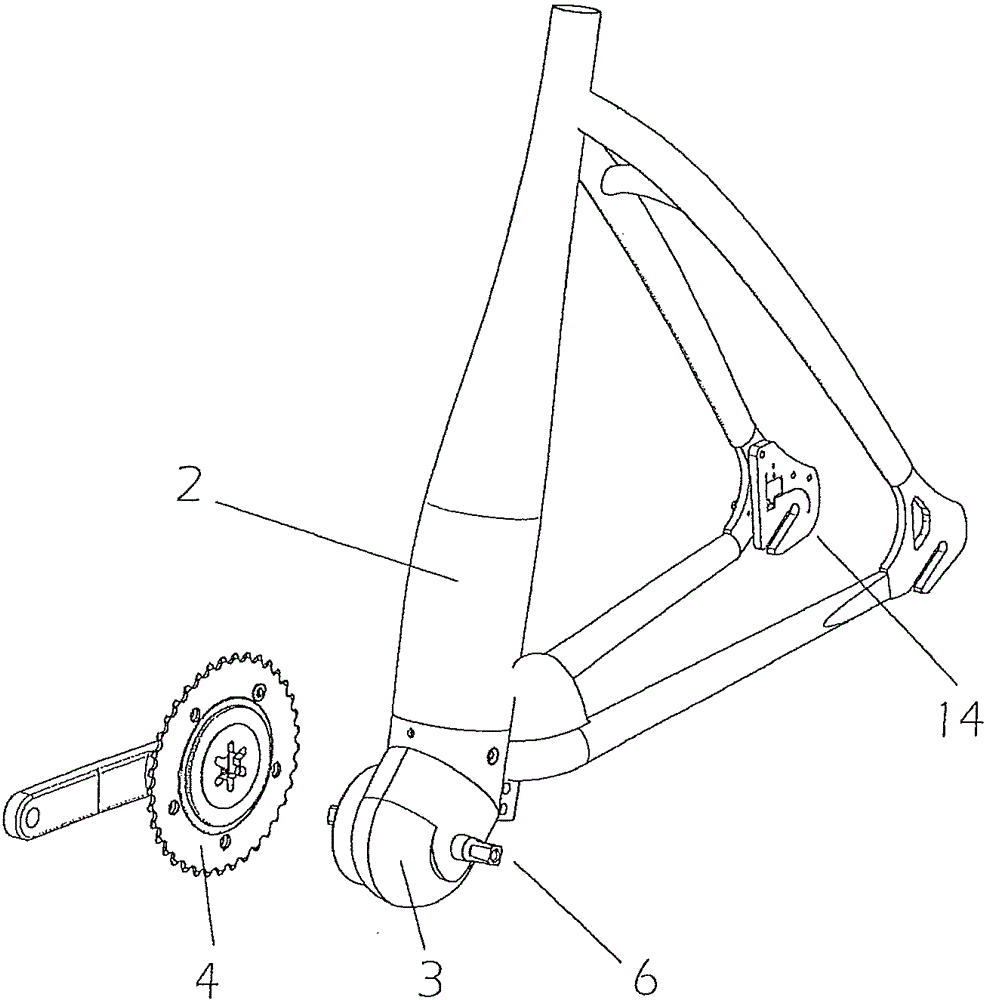

[0022] figure 1 and 1a A bicycle 1 is shown with a frame, in which a seat tube 2 can be seen. At the bottom of the seat tube 2, a bottom bracket 3 is attached, which includes within it a crankshaft 6 which transmits torque from the rider via the front sprocket 4 and chain 5 to the rear wheel , see also figure 2 . The seat tube 2 is manufactured such that the seat tube 2 includes a larger diameter at the lower end than at the upper end. The diameter at the lower end is increased so that an electric motor 7 can be accommodated on the underside of the seat tube (see image 3 ). The seat tube 2 tapers upwards from the lower part in which the electric motor 7 is housed to the usual diameter of the seat tube of a bicycle frame. The battery-powered electric motor 7 , not shown further here, comprises a driven shaft 8 , which is connected to a coupling element 16 by means of a drive train. The coupling element 16 is rigidly connected to the front sprocket 4 . The drive train ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap