Cold stamping process method for oil tank bracket of heavy vehicle

A process method, cold stamping technology, applied in the field of cold stamping process, to achieve the effect of eliminating thinning and out-of-tolerance, solving partial cracking, and improving the qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

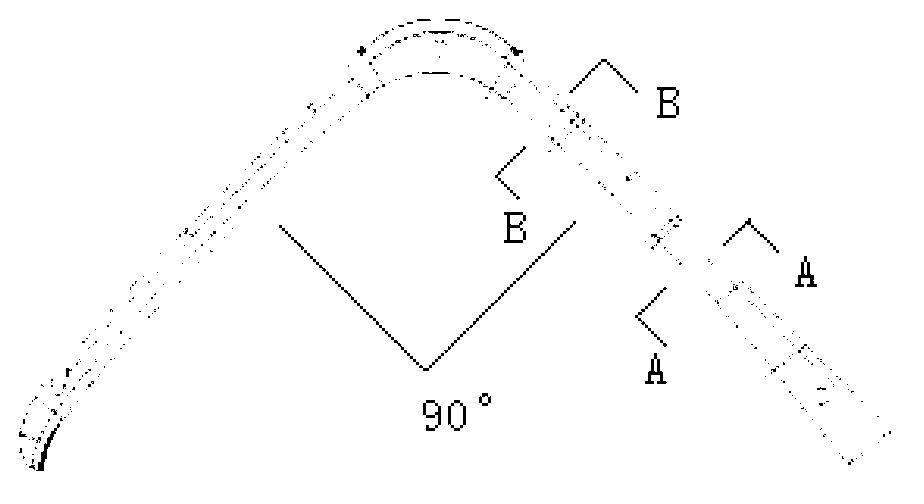

[0028] Such as Figure 8 As shown, the cold stamping process of the heavy-duty vehicle fuel tank bracket, the steps are as follows:

[0029] 1) Blanking; 2) Preforming 4; 3) Shaping 5; 4) Punching; 5) Punching.

[0030] Step 1) Blanking: drop out the shape of the blank.

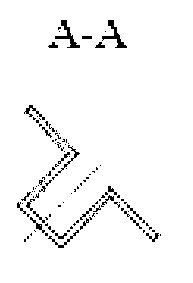

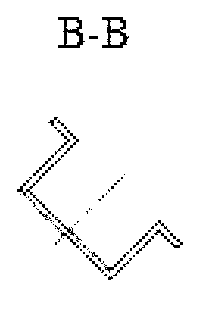

[0031] The preforming 4 in step 2) is: change the angle between the two arms from 120° to 130° on the blank to form a workpiece, and at the same time Shaped sections are formed in one step and pressed into place.

[0032] Reshaping 5 in step 3) is to perform angle shaping on the arc and straight line transition area of the workpiece, so that the angle between the two arms reaches the final 90° state of the product.

[0033] To determine the angle range of the angle between the two arms during preforming 4, it should be considered that no defects will occur in the subsequent shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com