Garbage conveying device

A garbage conveying and lifting device technology, which is applied in packaging and other directions, can solve the problems of non-environmental protection, low efficiency, unhygienic manual transportation of garbage, etc., and achieve the effect of increasing production capacity and environmental protection production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

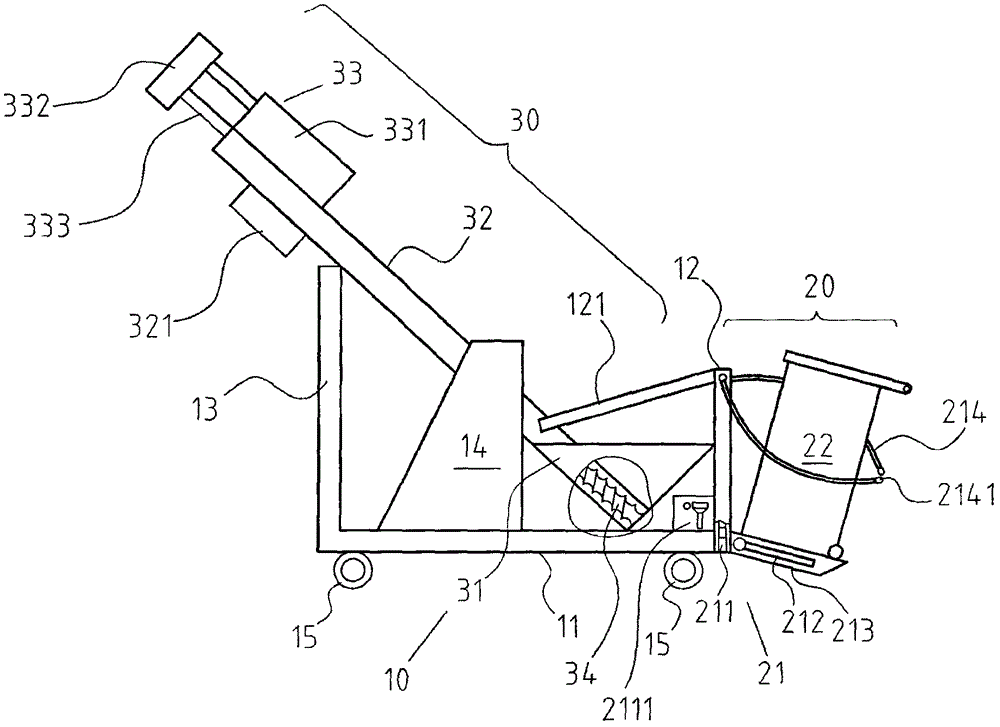

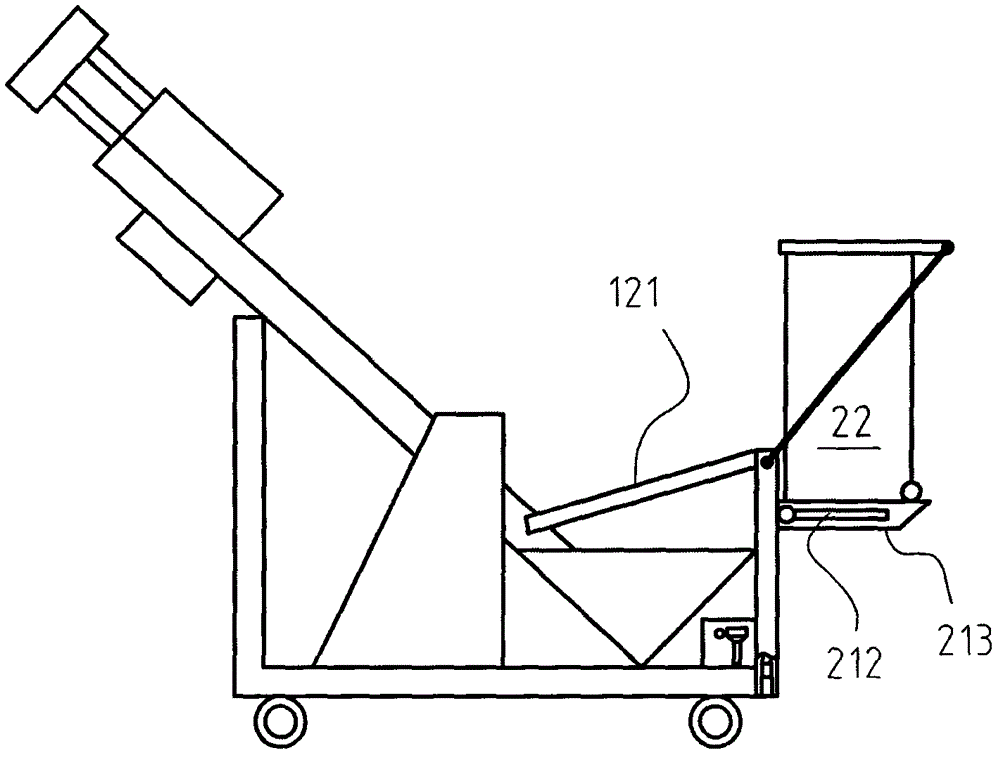

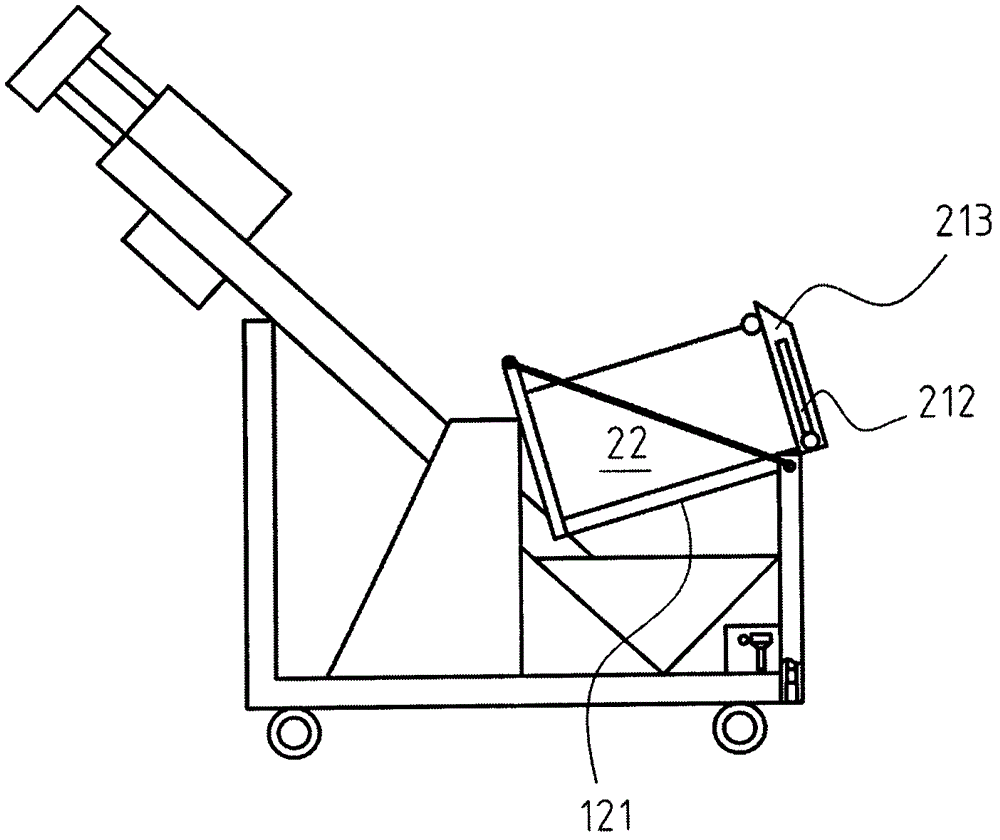

[0018] see figure 1 and combine figure 2 , image 3 As shown, a garbage conveying device is integrated with a primary transmission mechanism 20 and a secondary transmission mechanism 30 by a mobile vehicle 10, wherein:

[0019] Described mobile vehicle 10, comprises that base plate 11 is the front frame 12 of vertical installation of carrier, rear frame 13 and the bracket 14 that protrudes between these two, and the wheel 15 that this base plate 10 installs below; Between the frame 12 and the bracket 13, a trash can 22 inclined downwards is provided with a bracket 121 for dumping garbage;

[0020] The primary transmission mechanism 20 includes a trash can 22 carried by a lifting device 21; the lifting device 21 is installed on the vertical front frame 12 of the bottom plate 11, and includes a lifting oil pressure rod 211 that can move up and down and a flip The hand-operated oil pressure rod 212 that changes position, the lifting oil pressure rod 211 is connected to the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com