Ceramic inner-cylinder hanging piece for cement kiln preheater

A technology for preheaters and cement kilns, which is applied in the field of ceramic inner cylinder hanging pieces for cement kiln preheaters, can solve the problems of difficult adjustment of fit gaps and poor sealing performance, and achieve the goals of saving ceramic materials, improving sealing performance, and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings.

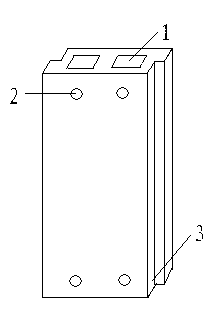

[0011] Such as figure 1 As shown, the hanging piece of the ceramic inner cylinder of the present invention is used for assembling the ceramic inner cylinder of the cement kiln preheater. The sheet through hole 1 facilitates the insertion and connection of the central connecting sheet. The perforated section of the central connecting sheet is rectangular; there are two central connecting sheet through holes 1 arranged side by side to form a double connection. The through hole 1 of each central connecting piece connects the upper and lower ends of the hanging piece, and is suitable for two groups of central connecting pieces to connect the upper and lower adjacent hanging pieces.

[0012] Mounting holes 2 are provided at both ends of the hanging piece. The mounting holes 2 are provided with two at the upper and lower ends respectively. The mounting holes 2 are used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com