Opening reducing device and processing method for reducing opening of air suction pipe of compressor

A suction pipe and necking technology, applied in the field of compressors, can solve the problems of leakage, uneven gap between the shell suction pipe and the enthalpy increasing suction pipe, etc., so as to reduce leakage, the gap is small and uniform, and the leakage is reduced. the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0027] According to the necking device in the first embodiment of the present invention, an air gun is used as the fluid driving device.

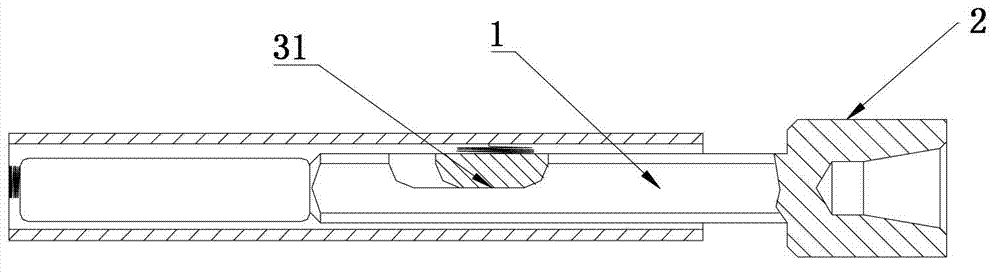

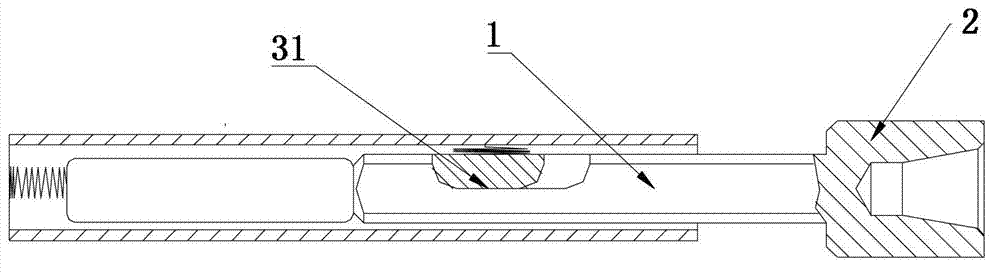

[0028] The necking tool includes a shaft 1 and a column head 2 arranged at the first end of the shaft 1 . The column head 2 is provided with a blind hole 21 located at the end away from the shaft 1, and the blind hole 21 includes a necking section whose diameter gradually decreases from outside to inside. Wherein, the wide mouth end of the necking section is located on the end face of the column head 2, so that the end of the pipe to be necked can be stretched into the necking tooling.

[0029] The air gun includes a gun barrel, the second end of the handle 1 is located in the barrel, and the handle 1 can extend and retract relative to the barrel.

[0030] Further, the necking device also includes a limiting device, which is used to limit the starting position and / or the ending position of the movement of the handle 1 relative to the bushi...

no. 2 example

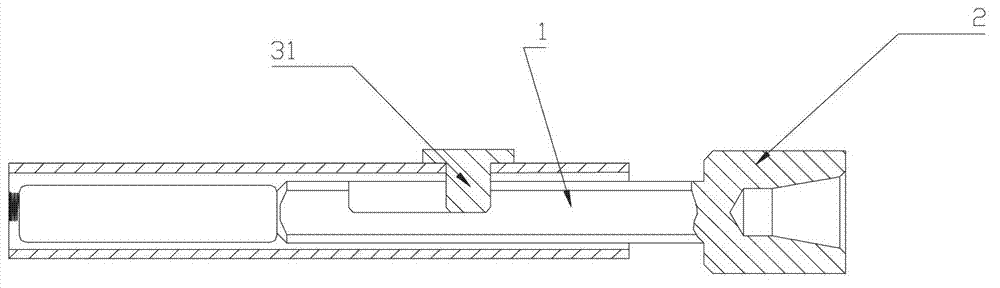

[0039] Such as image 3As shown, the necking device according to the second embodiment of the present invention also includes a necking tool and an air gun. The difference between the second embodiment and the first embodiment is that the gun barrel includes a pin hole, and the pin 31 penetrates through the pin hole and protrudes inward from the inner wall of the gun barrel. Others are the same as the first embodiment and will not be described here.

[0040] The present invention also provides a processing method for shrinking the suction pipe of the compressor, comprising:

[0041] Select the necking device so that the size of the blind hole of the necking device matches the suction pipe; align the necking section of the necking device with the nozzle of the suction pipe; start the fluid drive device to make the necking device The handle 1 of the fluid drive device moves in the direction of extension relative to the casing of the fluid drive device.

[0042] From the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com