Oil blockage cover on oil pan, and oil pan

A technology of oil pan and port cover, which is applied in the direction of engine components, machine/engine, engine lubrication, etc., and can solve problems such as oil leakage accidents, poor anti-loosening effect, and uneven tightening degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

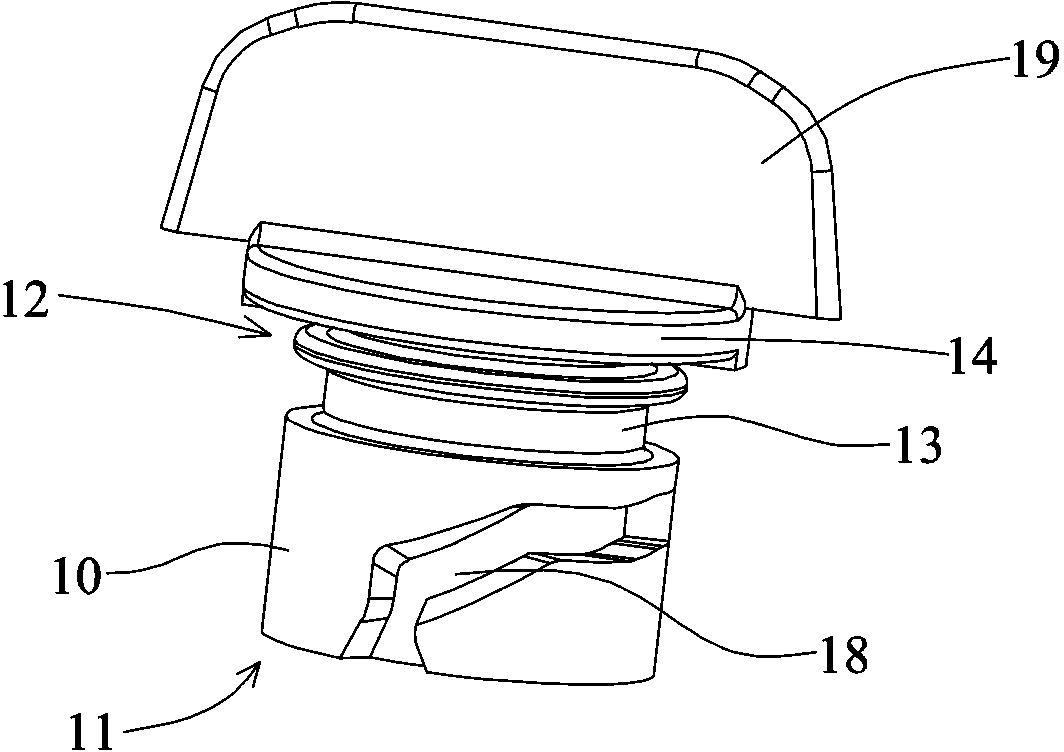

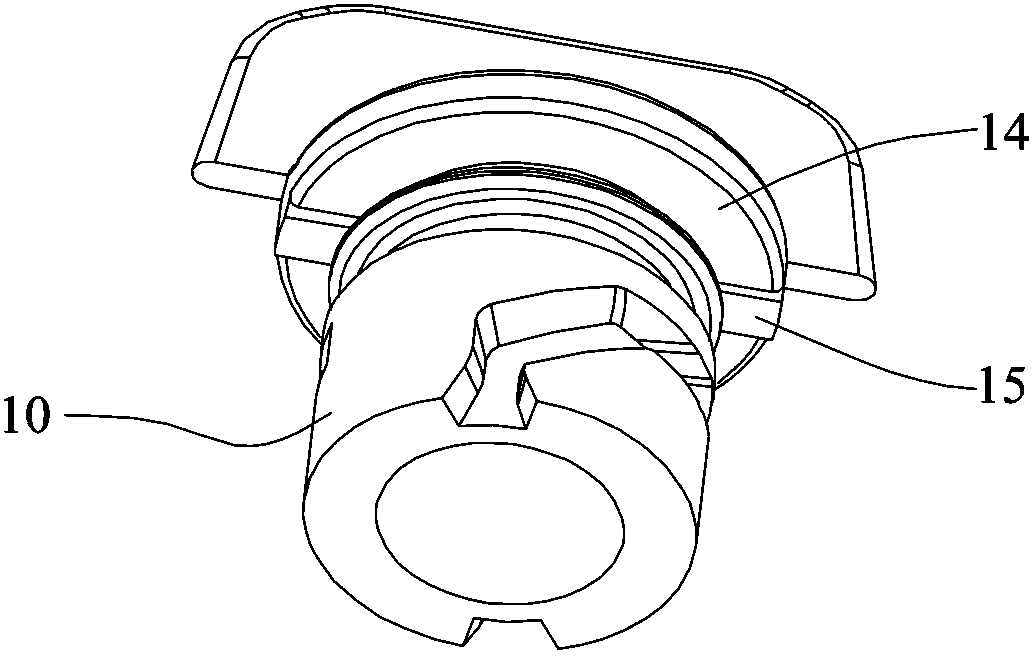

[0026] Such as Figure 1 to Figure 3 As shown, the oil pan oil plug cap of the present invention includes a columnar plastic body 10, one end of the body 10 is an insertion end 11, and the end opposite to the insertion end 11 is a cut-off end 12, which is fixed at the cut-off end 12. Connecting a boss 14, the end surface of the boss 14 connected with the body 10 is provided with a protruding clamping column 15, and a knob 19 is fixedly connected to the boss 14, and the side of the knob 19 protrudes from the boss 14 of the outer wall. An annular groove 13 is provided between the insertion end 11 and the cut-off end 12, and the annular groove 13 is used for inserting a sealing ring to play a role of sealing. The main body 10 is also provided with guide grooves 18 , and the said guide grooves 18 are provided as two or more than one arranged along the circumference of the axis of the main body 10 .

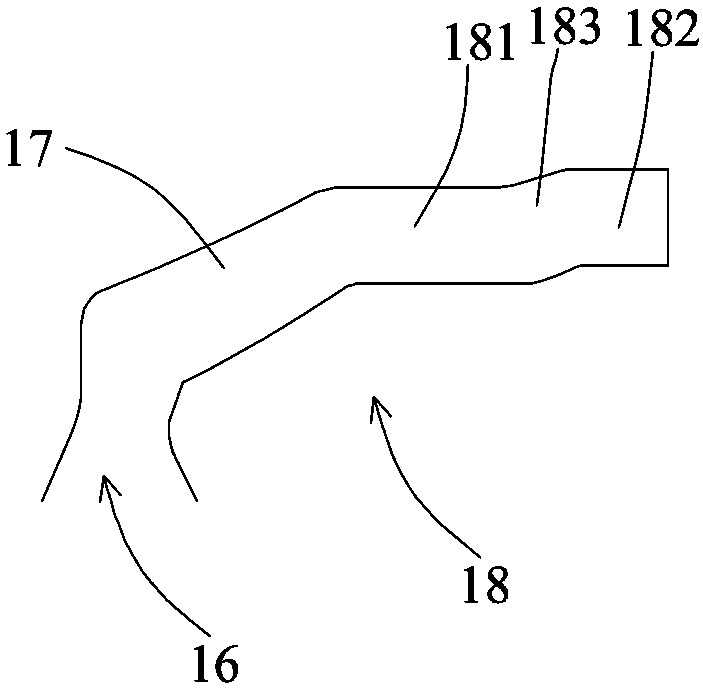

[0027] The guide groove 18 includes a section of guide groove 16 starting from ...

Embodiment 2

[0030] Such as Figure 4 and Figure 5 As shown, the embodiment of the present invention is an adaptive installation structure for the oil plug cover of the oil pan in the first embodiment, that is, an oil pan is disclosed, which includes a plastic shell 20, An oil drain hole 21 is provided on the casing 20 , and the oil drain hole 21 can be inserted into the body 10 . A guide column 22 corresponding to the guide groove 18 is provided in the drain hole 21, the width of the guide column 22 is not greater than the width of the guide groove 16 and the first transverse region 181 and the second transverse region 182, and can be freely positioned in the guide groove. 16 and slide in the first transverse zone 181 and the second transverse zone 182. On the outer end surface 26 of the oil drain hole 21 is provided a locking groove 23 , and the outer end surface 26 is provided with a slope 25 transitioning to the bottom of the locking groove 23 . The clamping slot 23 cooperates with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com