Automatic protection device of anti-explosive diesel engine

An explosion-proof diesel engine, automatic protection technology, applied in the direction of measuring devices, machines/engines, mechanical equipment, etc., can solve the problems of low degree of automation, single function, no introduction of combustible gas detectors, etc., to achieve the effect of preventing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings:

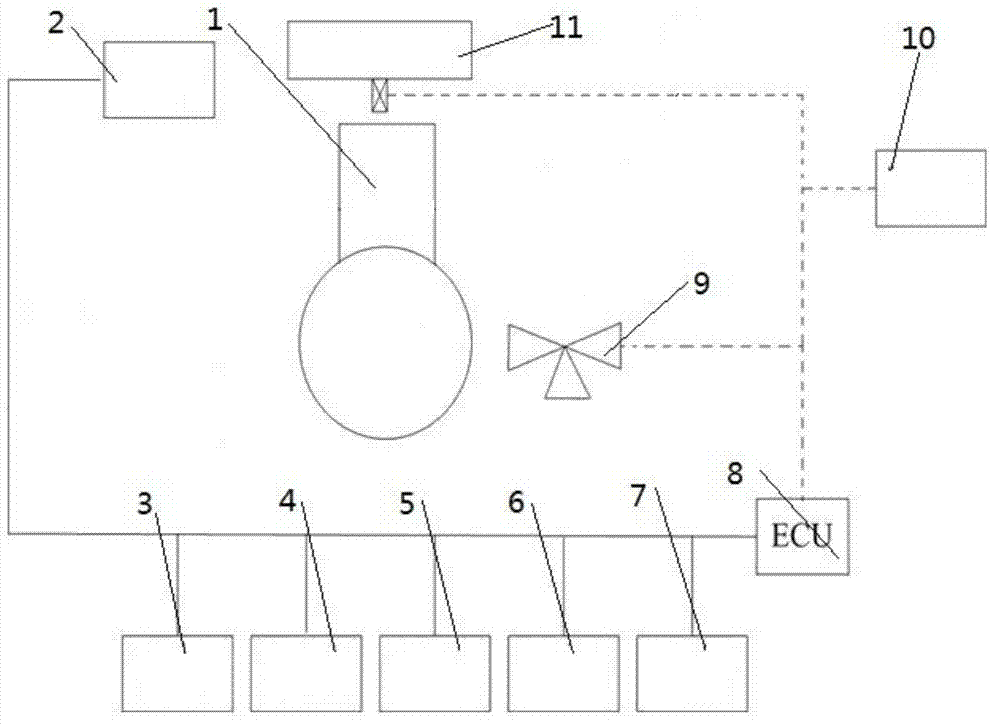

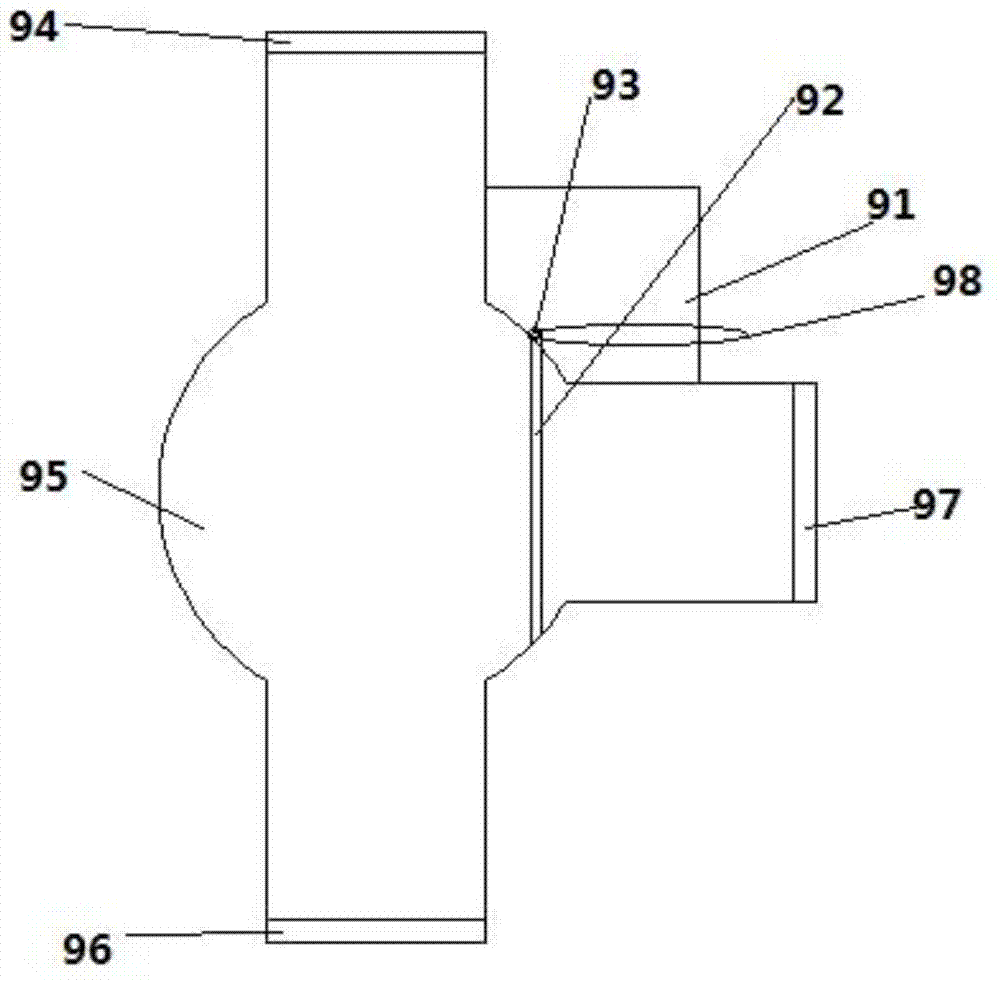

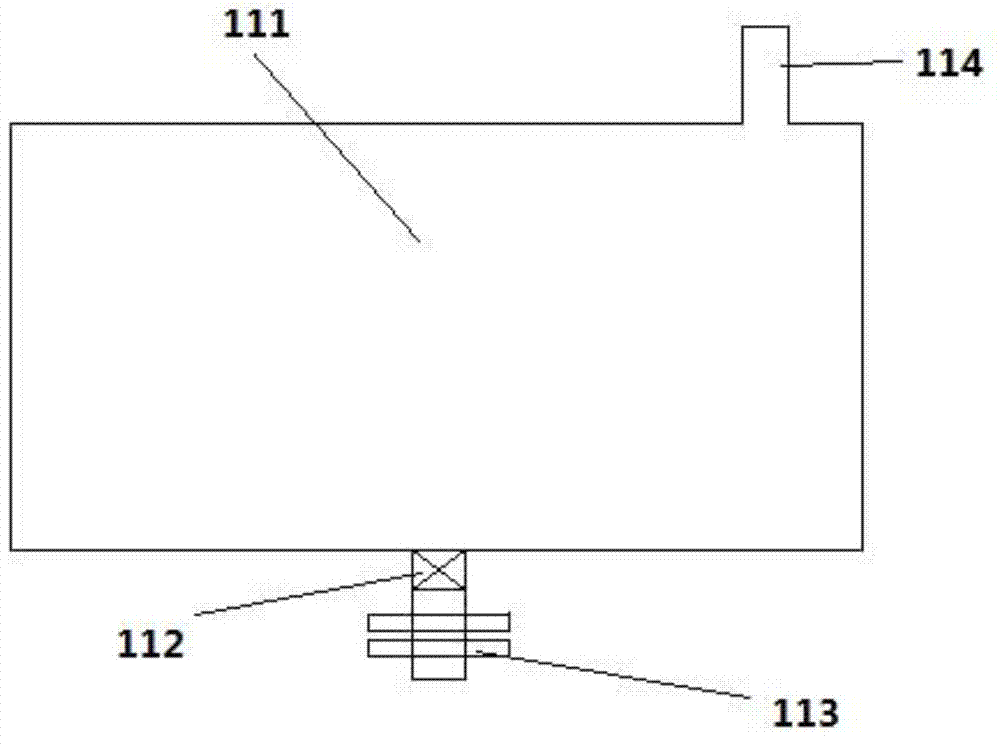

[0021] Such as figure 1 As shown, this embodiment includes an explosion-proof diesel engine 1, an infrared temperature measuring device 21, a combustible gas measuring device 3, a cooling water temperature sensor 4, a cooling water level sensor 5, an exhaust gas temperature sensor 6, an engine oil pressure sensor 7, and an electronic control unit ECU8 , Fuel shut-off valve 9, sound and light warning device 10, automatic fire extinguishing device 11.

[0022] The infrared temperature measuring device 2 is installed on the shell of the explosion-proof diesel engine, and it is separated from the explosion-proof diesel engine by a certain distance. The cooling water temperature sensor 4 and the cooling water level sensor 5 are installed in the cooling water tank of the explosion-proof diesel engine. The exhaust gas temperature sensor 6 is installed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com