Leakage prevention exhaust valve

A technology for exhaust valves and anti-leakage, applied to valve details, safety valves, balance valves, etc., can solve problems such as economic loss, water leakage, damage to valve well earthworks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

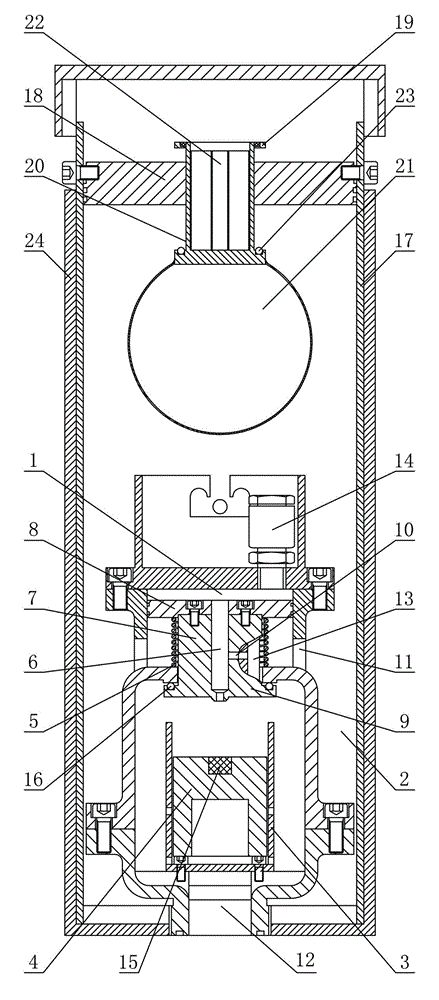

[0018] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

[0019] like figure 1 Shown, a kind of anti-leakage exhaust valve, it comprises exhaust valve and buoyancy check valve, and described exhaust valve is arranged in the valve body of described buoyancy check valve, and the valve of the valve body lower part of described buoyancy check valve The port is sealingly connected with the main valve cavity 2 of the exhaust valve. Here, the sealing connection adopts threaded connection and other applicable live connections, one is to play a sealing role to prevent leakage; the other is to be easy to disassemble and easy to maintain.

[0020] The buoyancy check valve includes a valve body consisting of a valve cylinder 17 and a valve cylinder sealing disc 18 sealingly arranged on the upper part of the valve cylinder 17, an exhaust cylinder 20 with a sealing disc baffle 19 arranged on the upper edge, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com