A manufacturing device for S-shaped metal honeycomb carrier

A technology of metal honeycomb carrier and manufacturing device, which is applied in the direction of metal processing equipment, etc., can solve problems such as difficulty in use, tooth shape deformation of honeycomb inner core, loose inner core, etc., and achieve the effects of avoiding deformation or even blockage, simple maintenance and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

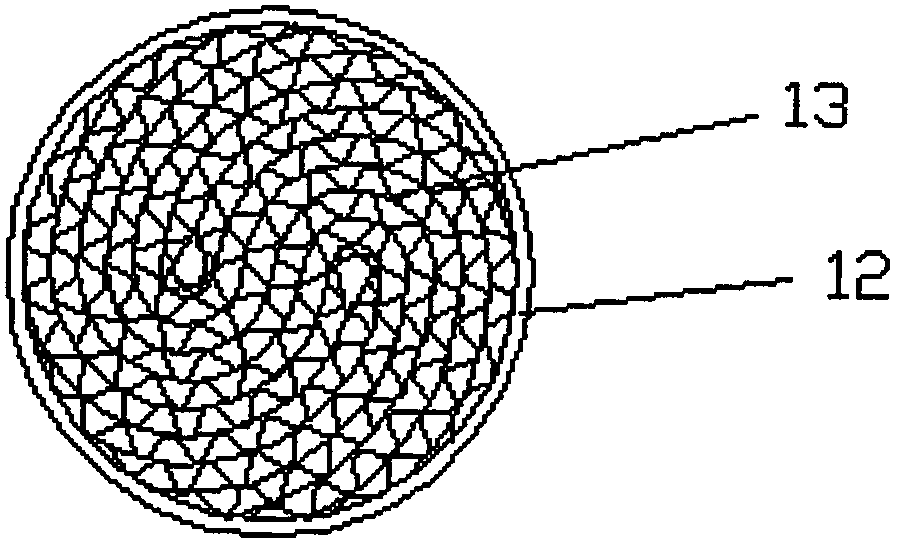

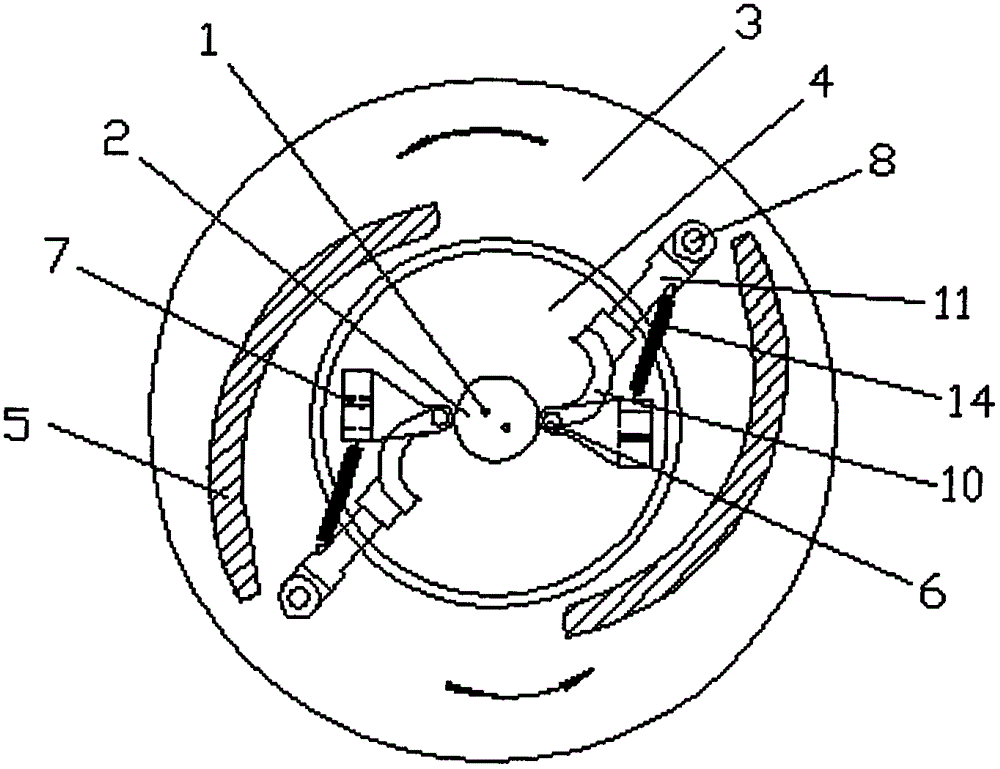

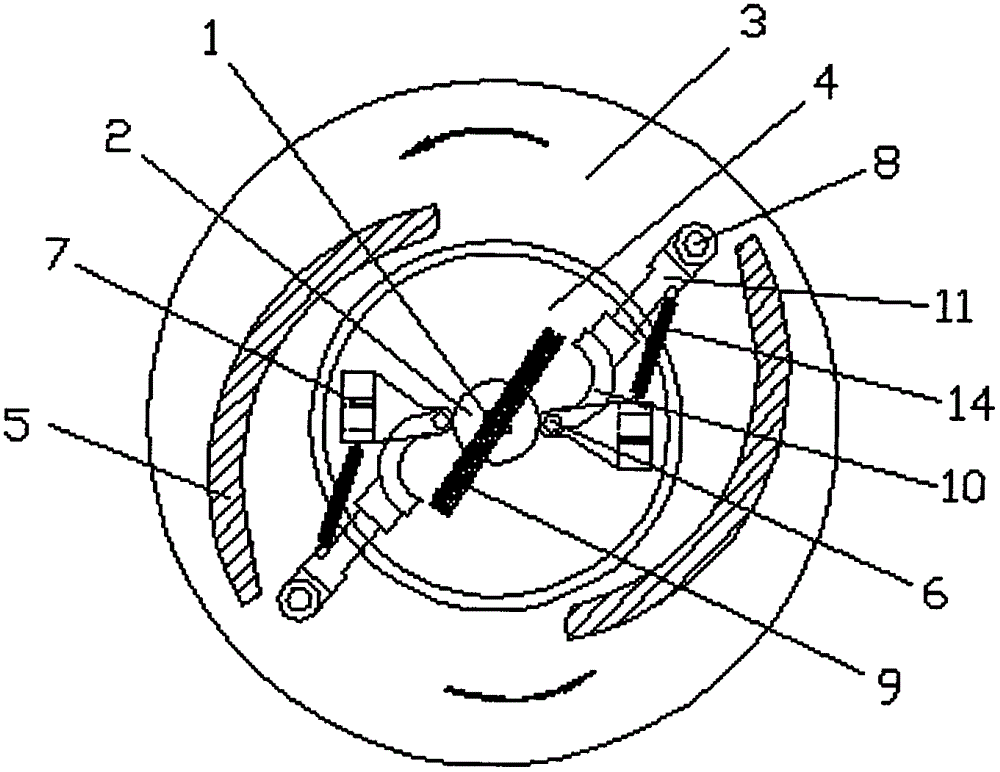

[0024] Implementation example 1: see Figure 3-Figure 5 , a manufacturing device of an S-shaped metal honeycomb carrier, comprising an inner disc 4, an outer disc 3 is arranged on the outer edge of the inner disc 4, an axial center hole and a fixed section 7 are arranged on the inner disc 4, and a fixed column is housed in the axial center hole 2. One end of the fixed section 7 is connected with a semicircular forming die 10 through a connecting shaft 6, the outer end of the semicircular forming die 10 is connected with a drive rod 11, and the other end of the fixed segment 7 is connected with the drive rod 11 through a spring device 14, so Said semicircular molding die 10 acts as closed molding, the outer end of drive rod 11 is equipped with bearing or bushing 8, said outer disc 3 is provided with arc-shaped parabolic protruding guide rail 5, said bearing or bushing 8 extends into the inner side of the arc-shaped parabolic raised guide rail 5; the cross-sectional shape of the...

Embodiment 2

[0027] Implementation example 2: see Figure 6-Figure 8 , except that the section of the fixed column 2 is elliptical and the molding die 10 is elliptical, the forming process is the same as that of Example 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com