Electric hammer

A technology of electric hammers and transmission parts, applied in nailing tools, manufacturing tools, etc., can solve problems such as uncompact structure, motor stall, crank slider mechanism can not achieve hitting, etc., to achieve the effect of compact structure and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

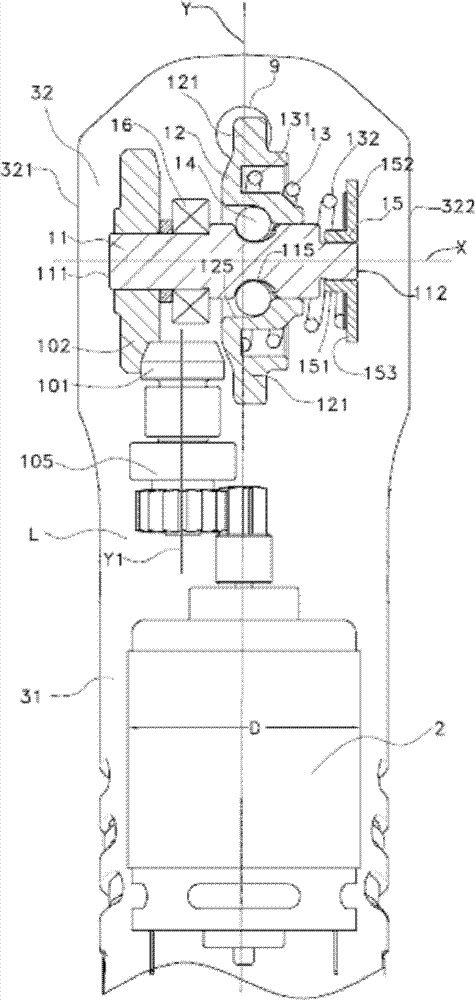

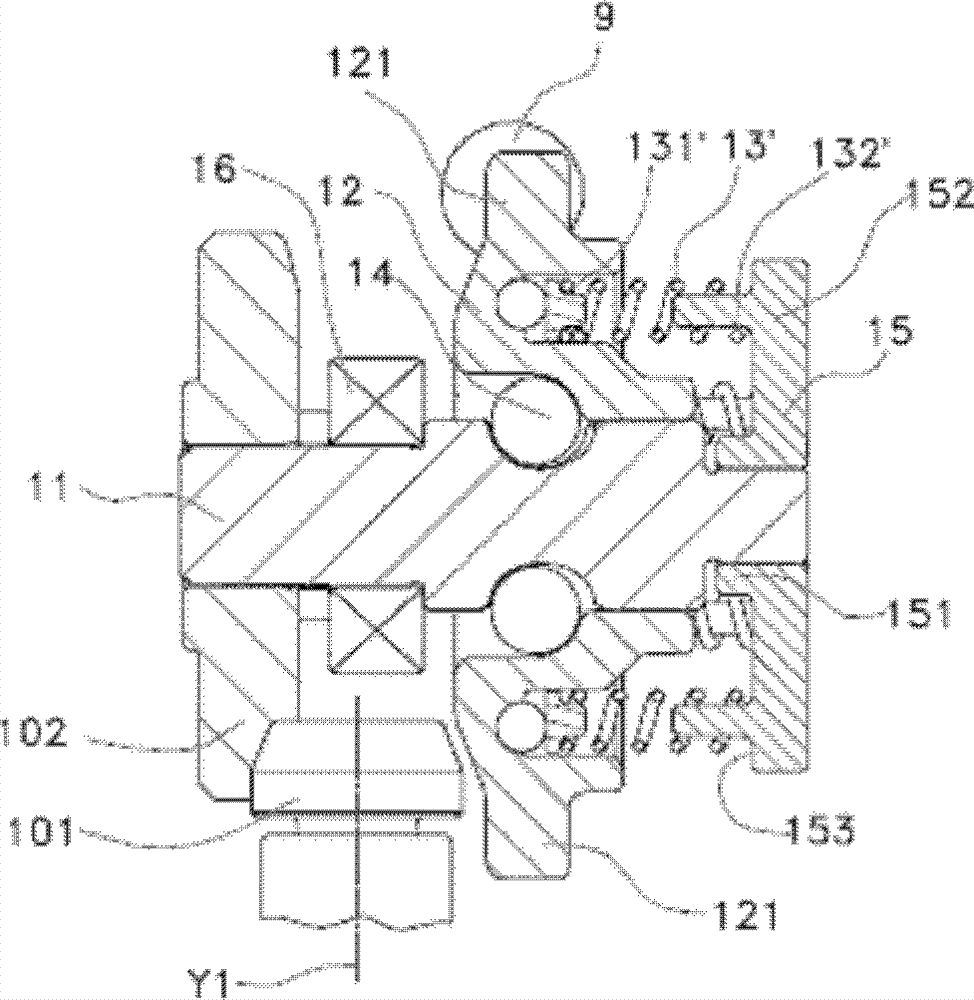

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

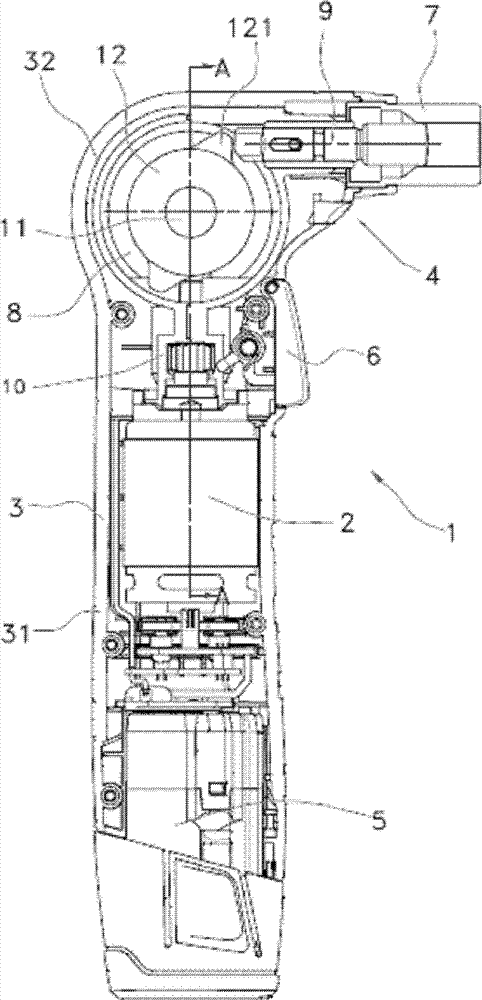

[0016] Such as figure 1 As shown, it is a schematic diagram of the electric hammer 1 of the present invention. The electric hammer 1 includes a casing 3, and the casing 3 is formed by combining two halves of the shell, and its main part forms a grip handle 31 in the longitudinal direction. The switch 6 for controlling the start and stop of the motor in the casing 3 is installed on the 31 position, the DC battery pack 5 is installed on the lower end of the casing 3, and the upper end head 32 of the casing 3 has a gun nozzle part 4, and the gun nozzle part 4 accommodates a nailing device 7 for driving fasteners such as nails.

[0017] In this embodiment, the battery pack 5 and the grip handle 31 are arranged substantially coaxially, the outer surfaces of the shell of the battery pack 5 and the casing 3 are adjacent to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com