Electric hammer

A technology of electric hammer and transmission parts, which is applied in the directions of striking tools, light impact tools, manufacturing tools, etc., can solve the problems of uncompact structure, locked rotor of the motor, and the crank-slider mechanism cannot achieve striking, etc., and achieves compact structure and size. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

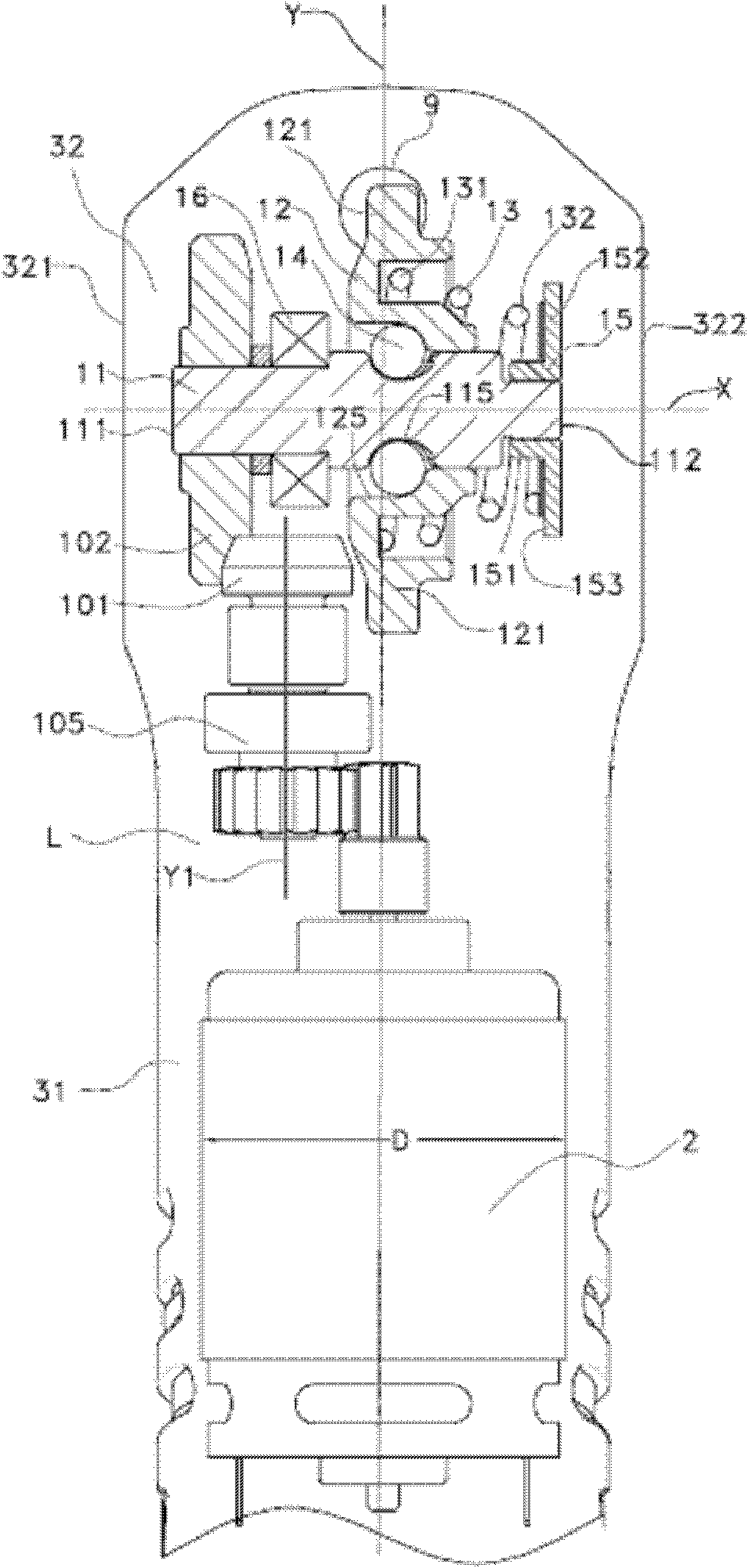

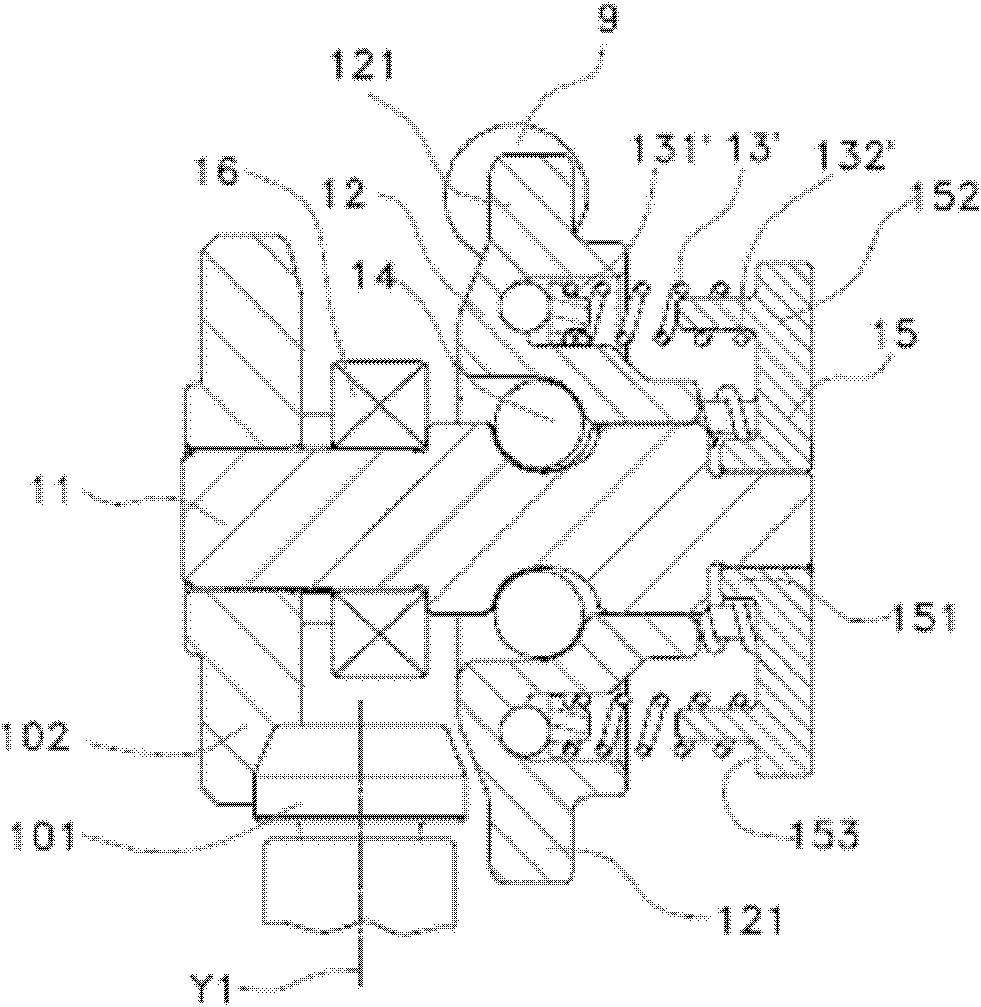

[0022] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

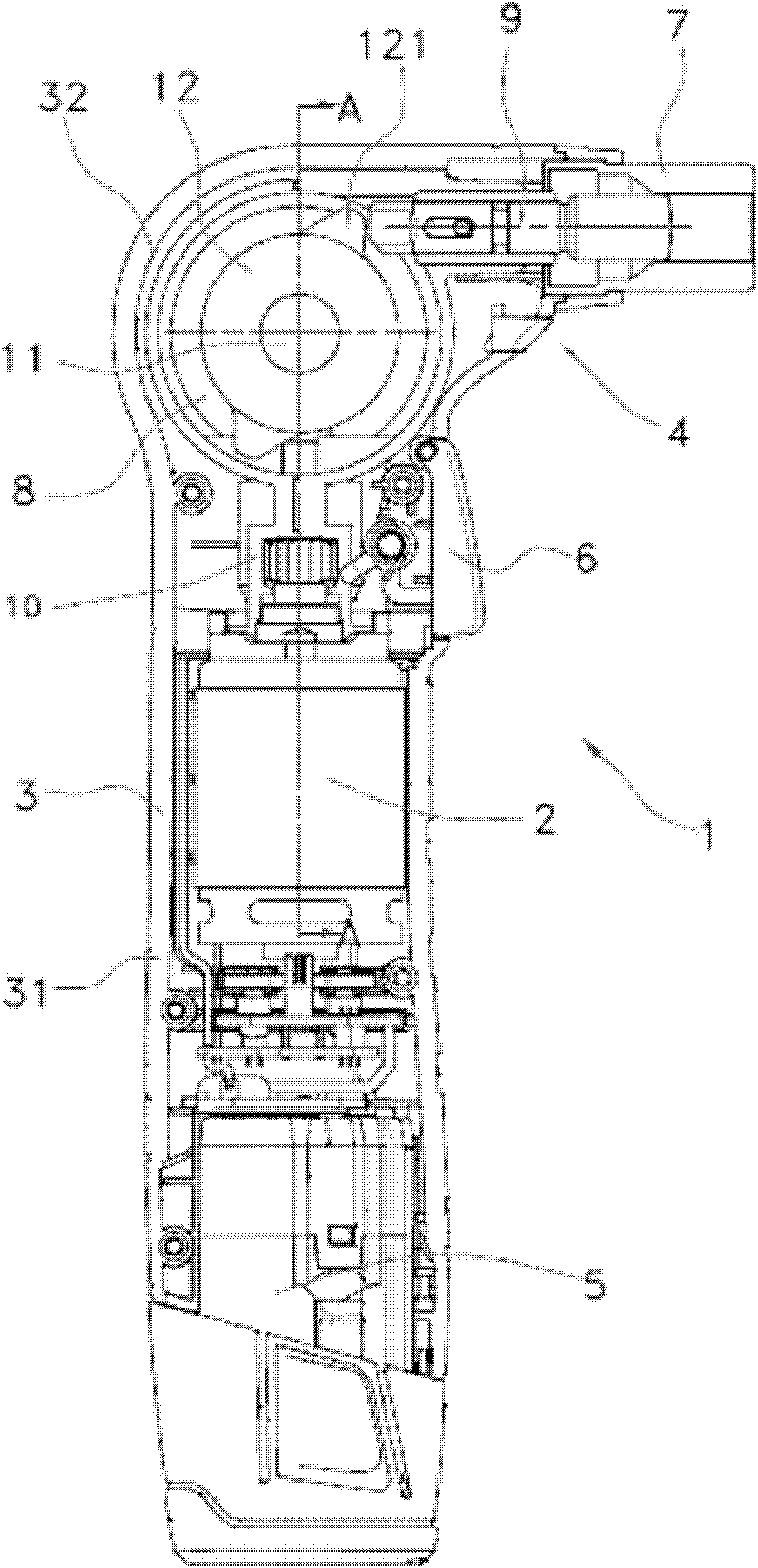

[0023] like figure 1 As shown, it is a schematic diagram of the electric hammer 1 of the present invention. The electric hammer 1 includes a casing 3. The casing 3 is formed by combining two half casings, and the main part thereof forms a longitudinally-long holding handle 31. The holding handle A switch 6 for controlling the start and stop of the motor in the casing 3 is installed on the 31 part, a DC battery pack 5 is installed on the lower end of the casing 3, and a gun nozzle part 4 is opened at the head 32 of the upper end of the casing 3. The gun nozzle part 4. A nailing device 7 for hitting fasteners such as nails is accommodated.

[0024] In this embodiment, the battery pack 5 and the handle 31 are arranged substantially coaxially, and the outer surfaces of the battery pack 5 and the casing 3 are adjacent to each other smoot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com