rubber track

A rubber track and track technology, applied in the field of rubber track, can solve the problems of rubber track durability decline, mandrel rust, etc., and achieve the effect of reducing spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

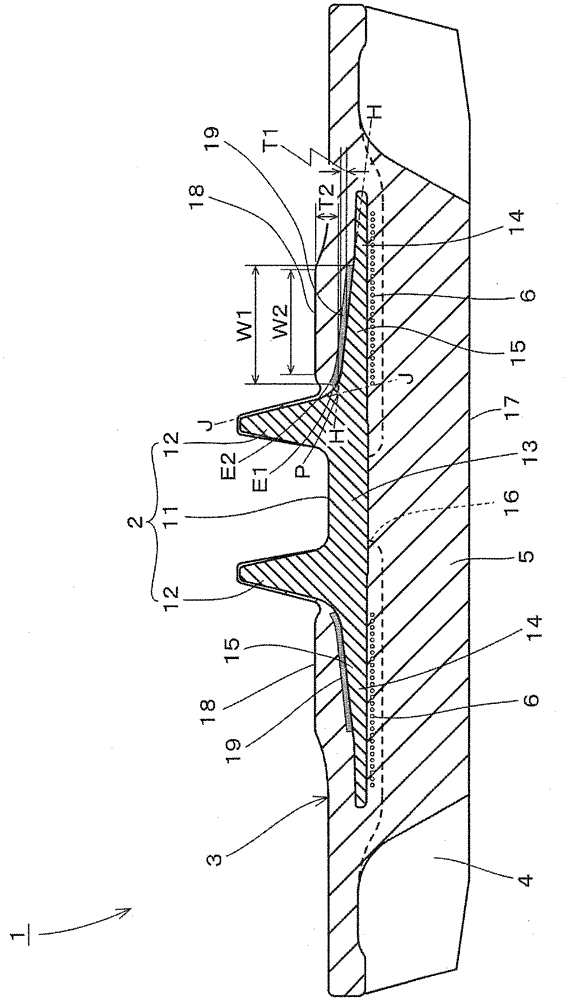

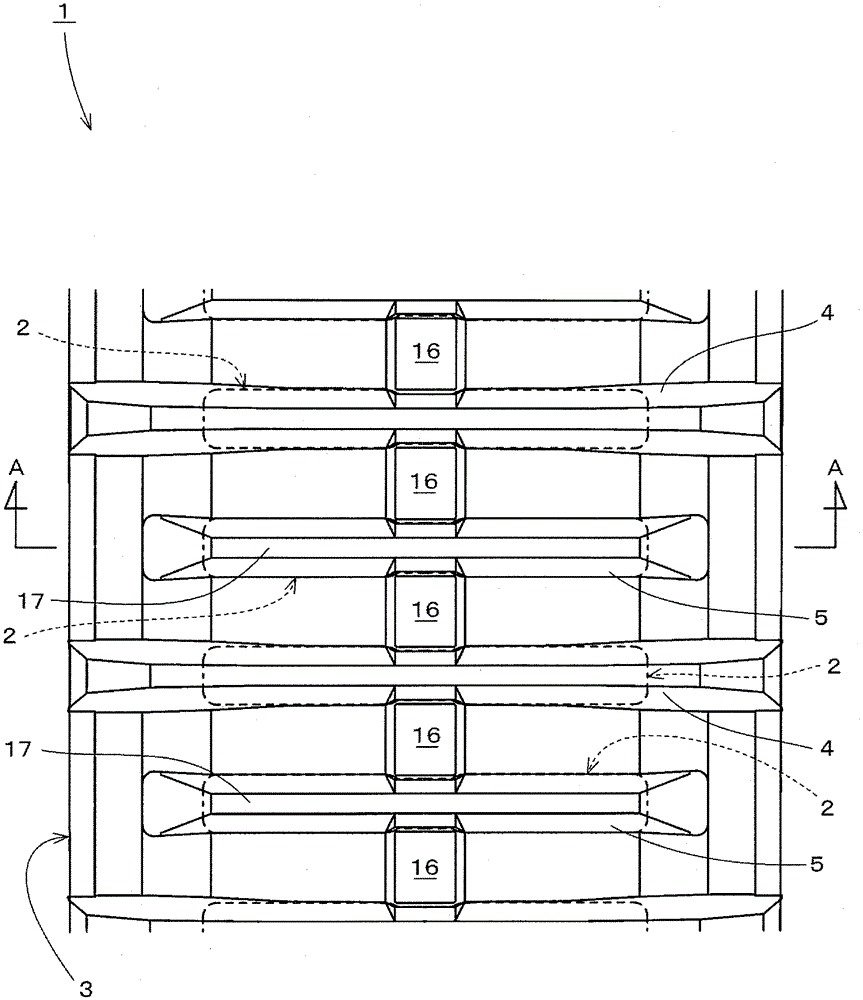

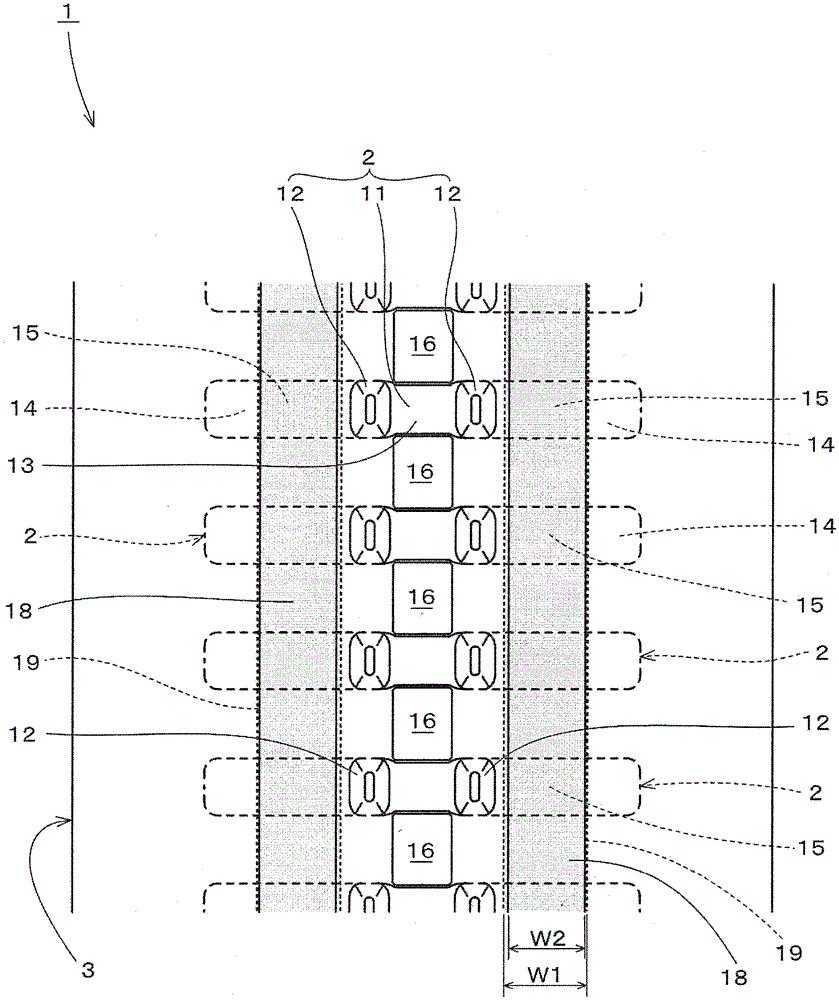

[0021] figure 1 is a cross-sectional view in the width direction of the rubber crawler 1, figure 2 It is the figure which looked at the rubber crawler 1 from the outer peripheral (grounding) side, image 3 It is a figure which looked at the rubber crawler 1 from the inner peripheral side. figure 1 yes figure 2 A-A to see the sectional view.

[0022] In the following description, when mounted on a crawler-type traveling vehicle, the ground contact side of the rubber crawler 1 is referred to as an "outer peripheral side", and the side opposite to the ground contact side is referred to as an "inner peripheral side". Also, the direction in which the rubber crawler 1 circulates when the crawler vehicle is running is referred to as the "circumferential direction", and the direction perpendicular to the circumferential direction and parallel to the rotation axis of the rollers of the crawler vehicle is referred to as the "width direction".

[0023] The rubber crawler 1 is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com