A kind of madecassoside liposome and its preparation method and application

A technology of madecassoside and oxaloside is applied in the field of madecassoside liposome and its preparation, and can solve the problems of incapability of multi-effect synergy, dermis layer affecting the use effect, unsuitable for large-area treatment and the like , to achieve the effect of promoting cell metabolism and cell regeneration, avoiding excessive proliferation and accelerating wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a preparation method of the above-mentioned madecassoside liposome, comprising the following steps:

[0032] (1) Preparation of oil phase: Melt phospholipids, cholesterol, and ceramide in a water bath at a temperature of 65-80°C, then add antioxidants, mix well, and set aside;

[0033] (2) Prepare the water phase: add madecassoside, polyol, and collagen into the purified water of the formula, stir and heat at 65-80°C to dissolve madecassoside, collagen, and polyol, and set aside;

[0034] (3) Preparation of colostrum: Add the oil phase prepared in step (1) dropwise to the water phase prepared in step (2) with constant stirring, and then emulsify at a high speed of 10,000 rpm for 2 min to obtain colostrum;

[0035] (4) Preparation of liposomes: heat the colostrum prepared in step (3) at 70°C, and then process it through high-pressure homogenization equipment with a pressure of 500 bar to 1500 bar and a cycle of 2 to 8 times. Cool down to 5...

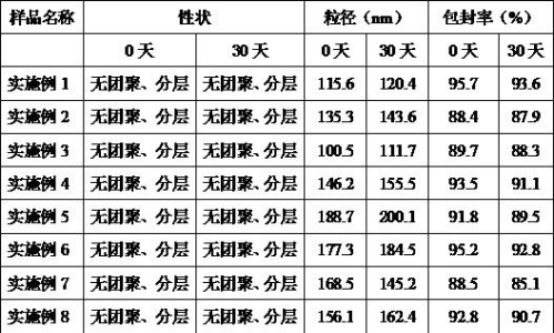

Embodiment 1

[0040] (1) Preparation of oil phase: Melt 3.0% soybean lecithin, 0.5% cholesterol, and 0.05% ceramide Ⅰ in a water bath at 65-80°C, then add 2.0% α-tocopherol, mix well, and set aside;

[0041] (2) Preparation of water phase: Add 0.1% madecassoside, 10.0% propylene glycol, 0.2% deep-sea cod skin collagen, 0.3% coconut collagen into 82.25% purified water, stir and heat at 65-80°C to dissolve ,spare;

[0042] (3) Preparation of colostrum: Add the oil phase prepared in step (1) dropwise to the water phase prepared in step (2) with constant stirring, and then emulsify at a high speed of 10,000 rpm for 2 min to obtain colostrum;

[0043] (4) Preparation of liposomes: heat the colostrum prepared in step (3) at 70°C, and then process it through high-pressure homogenization equipment with a pressure of 500 bar and 3 cycles, and cool down to 50°C;

[0044] (5) Add 0.4% rose essential oil, 0.1% shea oil, 0.1% fibroblast growth factor, and 1.0% honeysuckle extract to (4), stir evenly, 8...

Embodiment 2

[0046] (1) Preparation of oil phase: Melt 1.0% phosphatidylcholine, 2.0% egg yolk lecithin, 5% cholesterol, and 0.1% ceramide II in a water bath at 65-80°C, then add 1.5% α-tocopherol and mix well ,spare;

[0047] (2) Preparation of water phase: Add 5% madecassoside, 10.0% propylene glycol, 5.0% 1,3-butanediol, 0.5% deep sea cod skin collagen, 0.5% coconut collagen to 68.3% purified water , stir and heat at 65-80°C to dissolve, set aside;

[0048] (3) Preparation of colostrum: Add the oil phase prepared in step (1) dropwise to the water phase prepared in step (2) with constant stirring, and then emulsify at a high speed of 10,000 rpm for 2 min to obtain colostrum;

[0049] (4) Preparation of liposomes: heat the colostrum prepared in step (3) at 70°C, and then process it through high-pressure homogenization equipment at a pressure of 1000 bar, with 2 cycles, and cool down to 50°C;

[0050] (5) Add 0.1% carrot seed oil, 0.5% olive oil, and 0.1% fibroblast growth factor to (4),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com