Packing case and manufacturing method of packing case

A technology of packaging boxes and components, applied in the field of packaging, can solve the problems of reducing product costs, PP plastics are expensive, unfavorable, etc., and achieve the effect of reducing costs and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

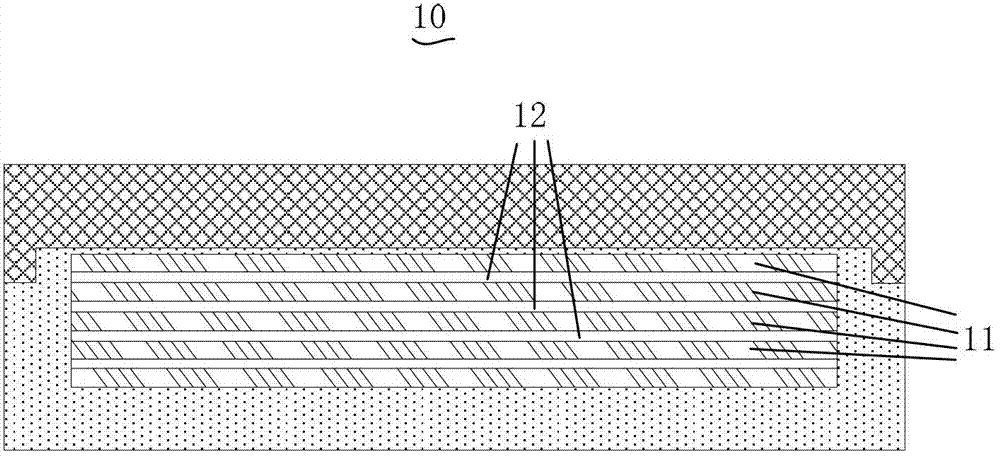

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

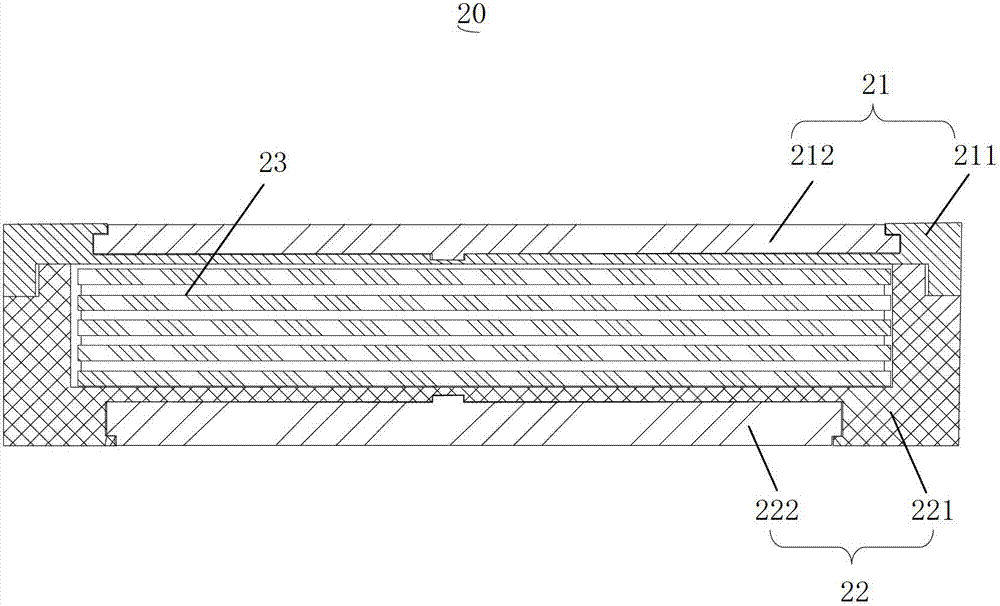

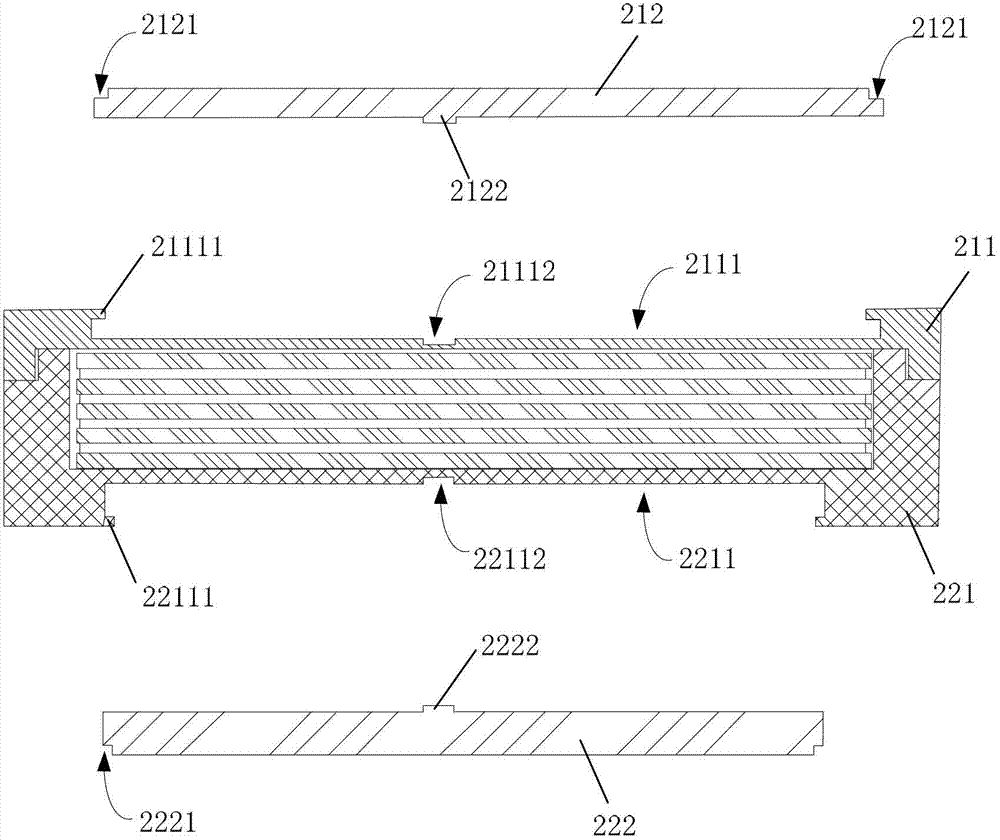

[0028] see figure 2 , image 3 and Figure 4 , figure 2 is a schematic cross-sectional view of an embodiment of the packaging box of the present invention, image 3 yes figure 2 An exploded schematic of the box shown, Figure 4 It is a three-dimensional exploded schematic view of the bottom cover in one embodiment of the packaging box of the present invention. As shown in the figure, the packing box 20 includes a top cover 21 and a bottom cover 22 . The top cover 21 includes a first member 211 and a second member 212 . The bottom cover 22 includes a third member 221 and a fourth member 222 .

[0029] The first member 211 directly supports the carrier 23 . The first member 211 has a first cushioning performance. Wherein, the first member 211 may be selected from a material with better cushioning performance, such as EPP (Expanded polypropy...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap