A blanking distribution device

A distribution device and blanking technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of inability to observe internal conditions, inconvenient maintenance, etc., and achieve the effect of tight closure, simple structure, and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

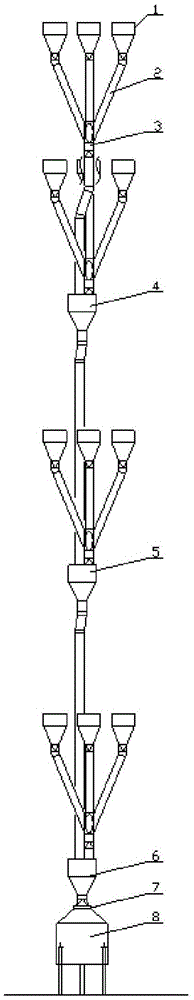

[0019] Such as figure 1 As shown, the blanking device of the present invention is a structure of a multi-layer funnel group, which includes a funnel group (1), a blanking pipe (2), a collection pipe (3), a first distribution bin (4), a second distribution bin (5), the third distribution bin (6), the bottom valve (7), and the bottom feed bin (8).

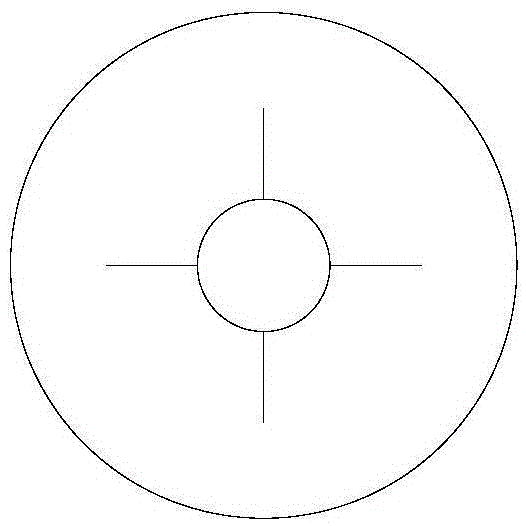

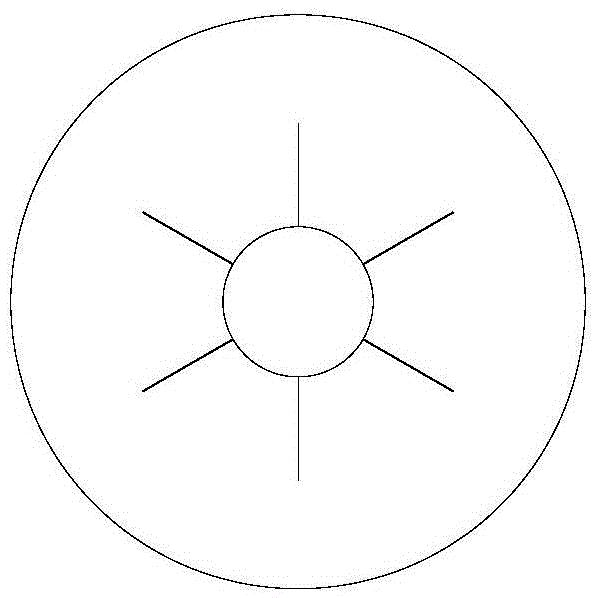

[0020] Each funnel group is filled with materials, in fact, the upper part of the funnel is the material layer. From the top to the bottom, there are the first layer of funnel group, the second layer of funnel group, the third layer of funnel group, and the fourth layer of funnel group. More material layers can be set according to the needs. The lower collecting pipe of the first funnel group and the collecting pipe of the second funnel group meet at the first distribution chamber (4), and the number of blades in the middle rotor group of the first distribution chamber is 4 pieces. The material pipe at the lower part of the first d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com