A method and device for extracting 2,6-xylenol from crude phenol

A technology of xylenol and crude phenol, which is applied in the field of coal chemical industry and can solve problems such as poor selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

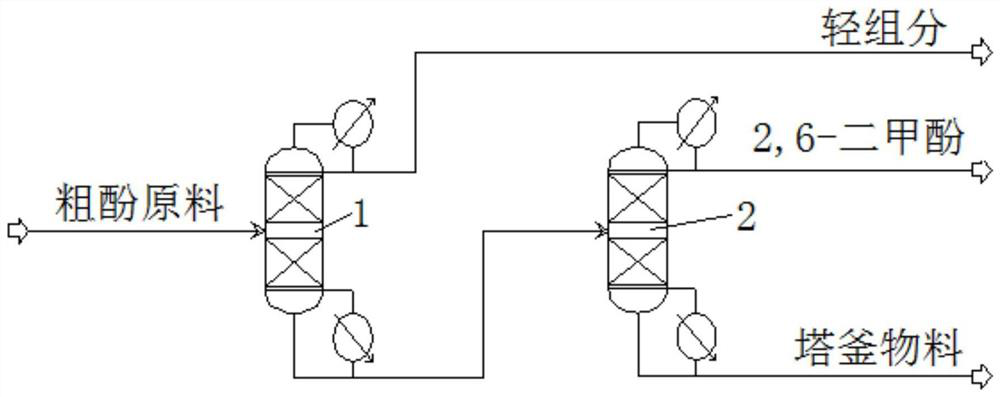

[0037] This embodiment provides a method for extracting 2,6-xylenol from crude phenol, comprising the steps of:

[0038] 1) Select the crude phenol raw material, which contains light components such as 0.18wt% phenol, 5.03wt% 2,6-xylenol, 66.51wt% m-p-cresol and 28.28wt% other dicresols in this crude phenolic raw material heavy components such as cresol, and preheat the crude phenol raw material to 155°C;

[0039] 2) The crude phenol raw material preheated in step 1) is continuously sent into the first-stage rectification column with a flow rate of 2.5t / h to carry out the first-stage rectification treatment, and the operating pressure of the first-order rectification treatment is controlled at 25KPa, and the operating temperature is The temperature is 130°C, the reflux ratio is 14, and the light components lighter than 2,6-xylenol are removed, and drawn from the top of the primary distillation tower, and the primary distillation product is collected from the bottom of the towe...

Embodiment 2

[0042] This embodiment provides a method for extracting 2,6-xylenol from crude phenol, comprising the steps of:

[0043]1) Select the crude phenol raw material, which contains light components such as 0.22wt% phenol, 2.07wt% 2,6-xylenol, 66.56wt% m-p-cresol and 31.15wt% other dicresols in this crude phenolic raw material heavy components such as cresol, and preheat the crude phenol raw material to 154°C;

[0044] 2) The crude phenol raw material preheated in step 1) is continuously sent into the first-stage rectification column with a flow rate of 2.5t / h to carry out the first-stage rectification treatment, and the operating pressure of the first-order rectification treatment is controlled to 0.5Pa. The temperature is 160°C, the reflux ratio is 5, and the light components lighter than 2,6-xylenol are removed, and drawn from the top of the first-stage rectification tower, and the first-stage rectification product is collected from the bottom of the tower, and the first-stage re...

Embodiment 3

[0047] This embodiment provides a method for extracting 2,6-xylenol from crude phenol, comprising the steps of:

[0048] 1) Select the crude phenol raw material, which contains light components such as 0.05wt% phenol, 15wt% 2,6-xylenol, 60wt% m-p-cresol and 24.5wt% other xylenols in this crude phenolic raw material Equal weight components, and preheat the crude phenol raw material to 153°C;

[0049] 2) The crude phenol raw material preheated in step 1) is continuously sent into the first-stage rectification column with a flow rate of 2.5t / h to carry out the first-stage rectification treatment, and the operating pressure of the first-order rectification treatment is controlled at 50KPa, and the operating temperature is The temperature is 100°C, the reflux ratio is 20, and the light components lighter than 2,6-xylenol are removed, and drawn from the top of the primary distillation tower, and the primary distillation product is collected from the bottom of the tower, and the prim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com