Graduation system and method for lithologic density instrument

A technology of lithology density and calibration method, which is applied in the direction of instruments, earthwork drilling and production, boreholes/well components, etc., can solve the problems that workers are easily exposed to relatively large radiation, reduce calibration workload, shorten calibration time, improve The effect of security conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

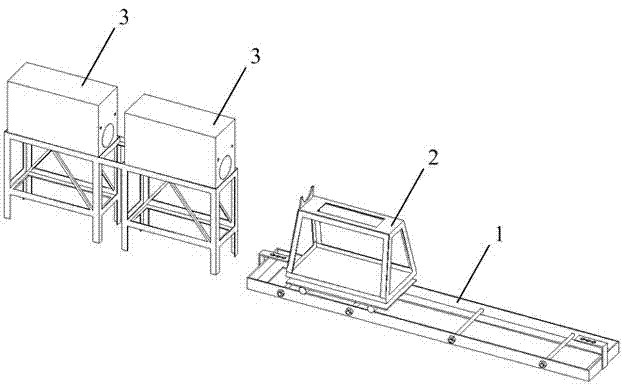

[0021] Such as figure 1 As shown, the lithology density instrument calibration system of the embodiment of the present invention mainly includes a linear track 1, a lithology density instrument (not shown in the figure), a magnesium block and an aluminum block, and the like. The lithology density instrument is arranged on the linear track 1 through the rail car 2, and the rail car 2 can carry the lithology density instrument to move linearly along the linear track 1. The magnesium block and the aluminum block are arranged on the extension line in the same direction of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com