Optical cable dryer

A technology of blow dryer and optical cable, which is applied in the direction of drying, drying machine, drying gas arrangement, etc. It can solve the problems of excessive noise in the workshop, increased noise of workshop equipment, and increase in the number of compressor unit equipment, etc., to achieve large market development and Promote value, reduce water blowing noise, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

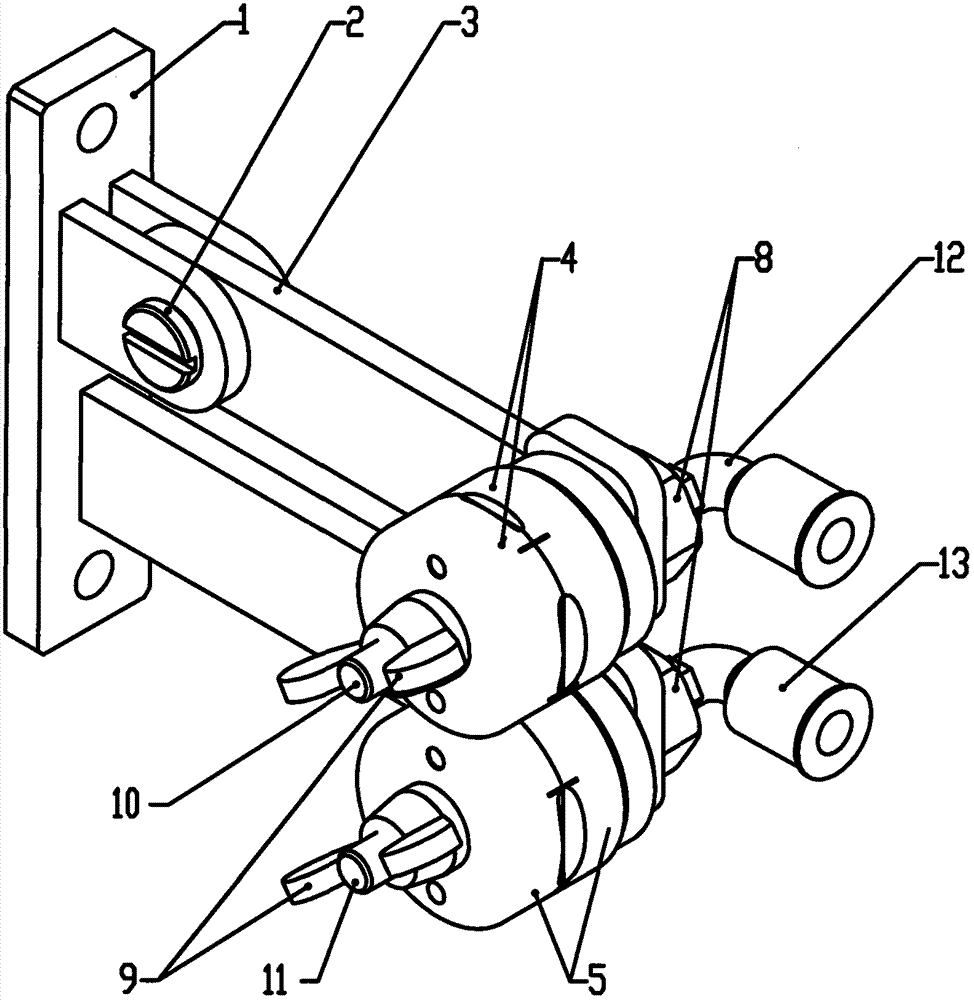

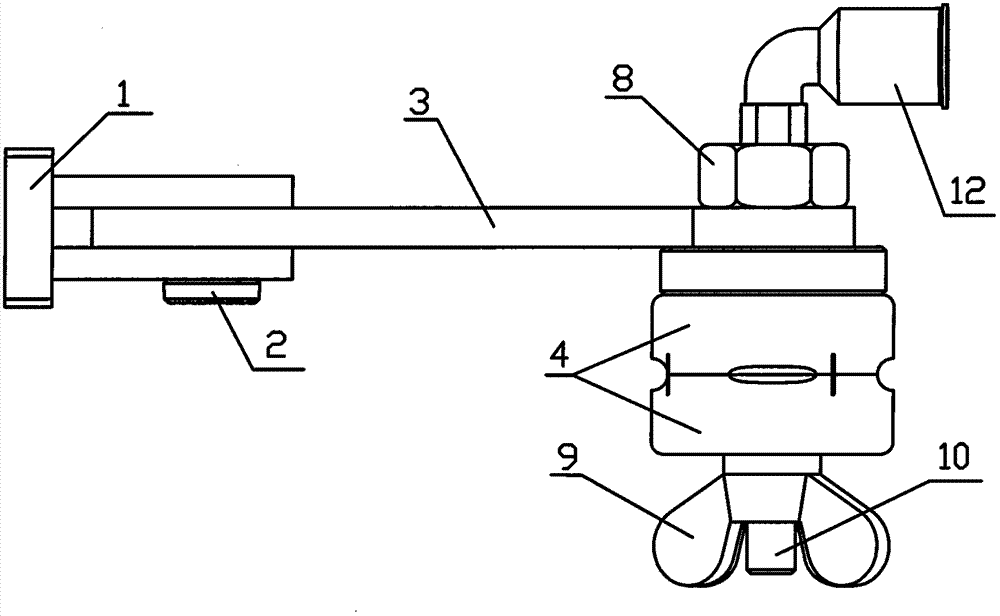

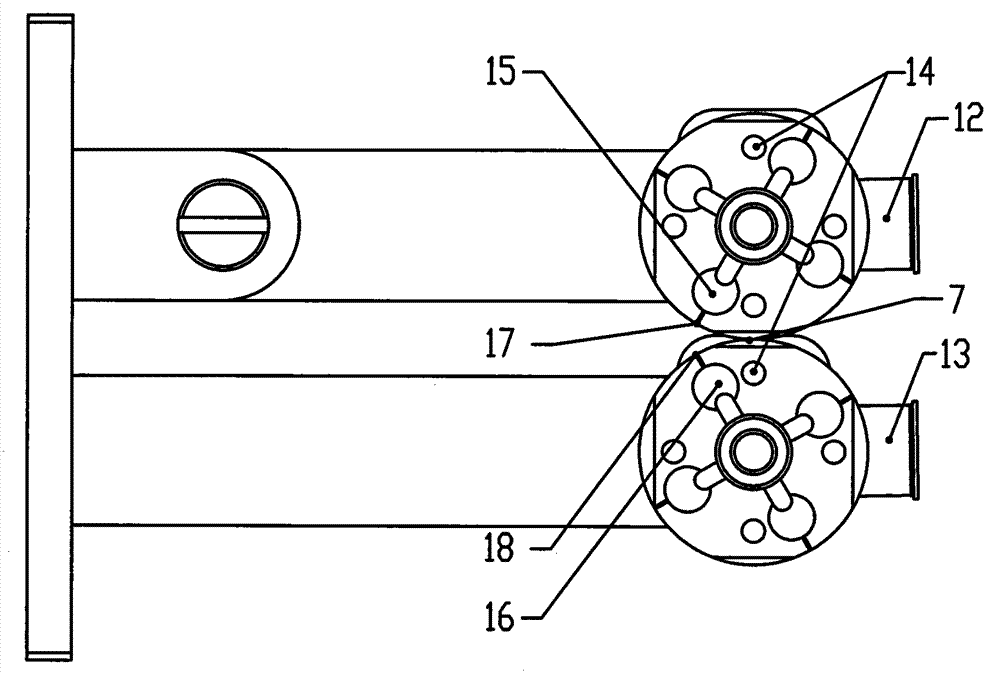

[0027] see figure 1 As shown, the fiber optic cable blower provided by the embodiment of the present invention includes a blower bracket, four water blowing boxes (two upper water blowing boxes 4, two lower water blowing boxes 5), an upper air inlet bend Head 12 and lower intake elbow 13, the dryer bracket includes a mounting plate 1, a movable pole 3 and a fixed pole, one end of the fixed pole is fixed on the mounting plate 1, and the end of the movable pole 3 is close to the mounting plate 1 It is connected with the mounting plate 1 through the hinge screw 2, which is convenient to operate during production. When the optical cable product produced is larger than the design diameter, the movable support rod 3 can be automatically lifted under the action of inertia to prevent damage to the equipment and the optical cable.

[0028] se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com