Polymer dielectric electrostatic polarization device and electrostatic polarization method thereof

A dielectric and polymer technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

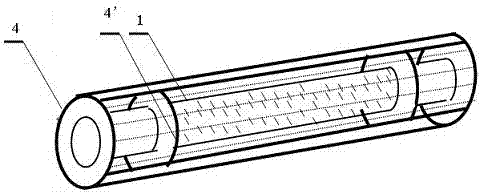

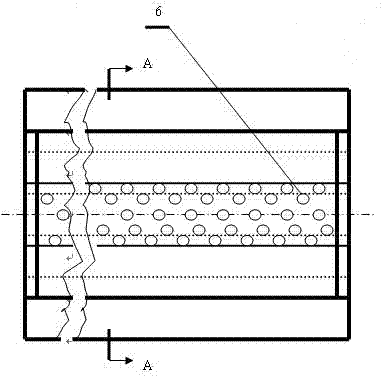

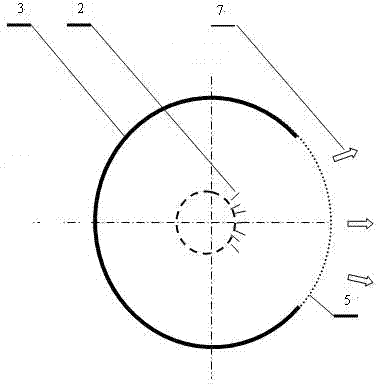

[0032]The electrode system structure of the electrostatic polarizer of the present invention is as follows: on the electric conductor rod or electric conductor pipe of appropriate length, the present embodiment is that the needle-shaped electrode array 2 is arranged on the appropriate circumferential angle range on the metal pipe 1, and A firm electric conductor cover is coaxially installed on the periphery of the tube 1. In this embodiment, the electric conductor cover is a metal cover 3. Both the metal cover 3 and the metal tube 1 are fixed on the anti-discharge high-voltage insulator 4. The metal cover 3 faces the needle-shaped One side of the electrode array 2 is opened and an electric conductor grid is set. The electric conductor grid in this embodiment is a metal grid 5, and the metal grid 5 is also fixed on the anti-discharge high-voltage insulator 4 between the metal cover 3 and the metal grid 5 'On, and with the metal cover 3 and the metal tube 1 and needle electrode a...

Embodiment 2

[0036] On the basis of the polarization device in Example 1, the three-layer composite membrane of 12 μm thick PFA non-porous membrane / 220 μm thick ePTFE porous membrane / 12 μm thick PFA non-porous membrane is polarized and deposited under the same conditions as in Example 1 Aluminum electrodes, stable polarization process, quiet, no light, no sparks. The quasi-static piezoelectric constant d of the space-charge porous piezoelectric film thus prepared 33 1240pC / N.

Embodiment 3

[0038] On the basis of the polarizing device in Example 1, a three-layer composite membrane of 15 μm thick FEP non-porous membrane / 220 μm thick ePTFE porous membrane / 15 μm thick FEP non-porous membrane is polarized and deposited under the same conditions as in Example 1 Aluminum electrodes, stable polarization process, quiet, no light, no sparks. The quasi-static piezoelectric constant d of the space-charge porous piezoelectric film thus prepared 33 1280pC / N.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap