Pump Tappet

A pump and housing technology, applied in the direction of pumps, multi-cylinder pumps, fuel injection pumps, etc., can solve problems such as mid-sole damage, and achieve the effects of suppressing beating, good efficiency and good roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

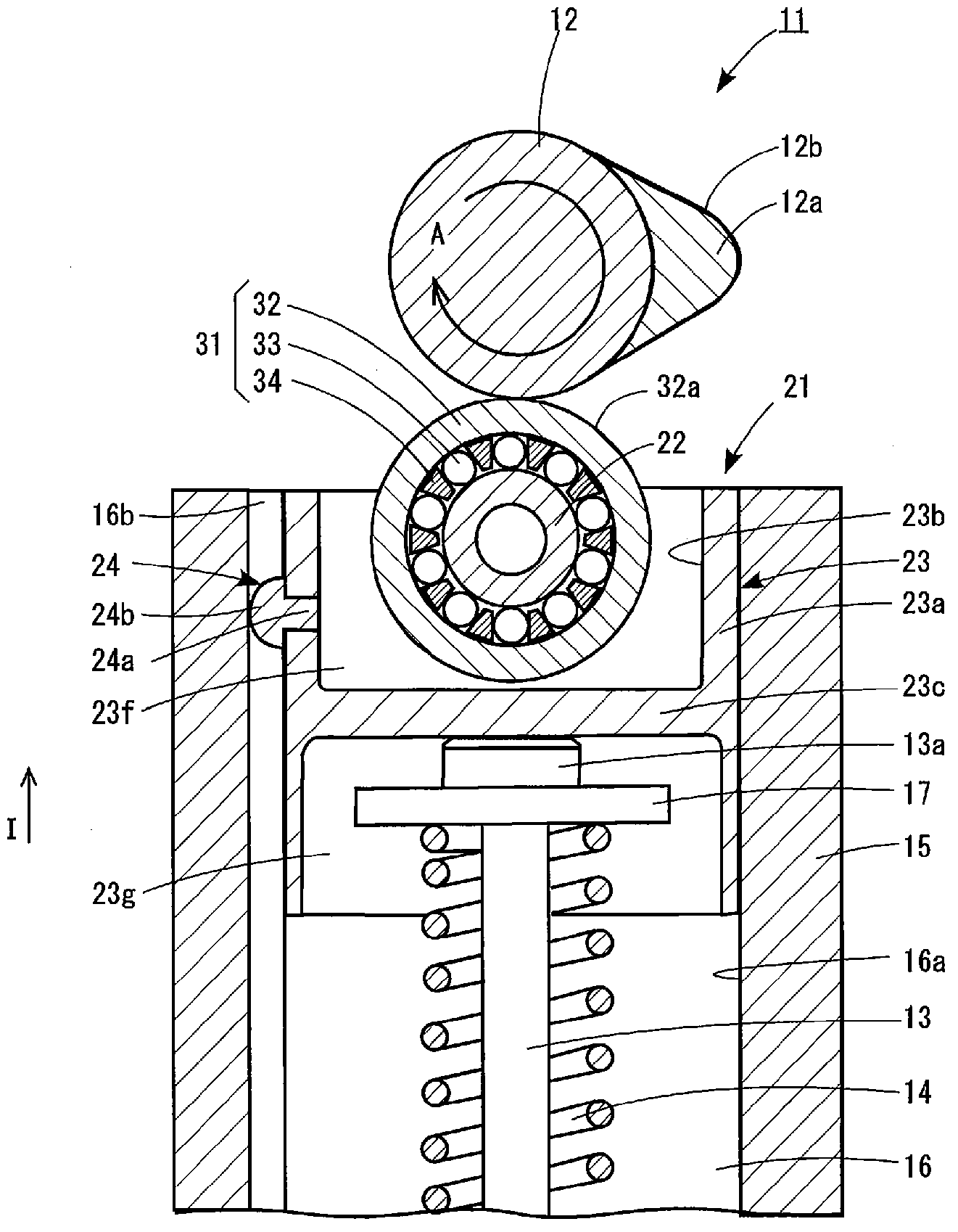

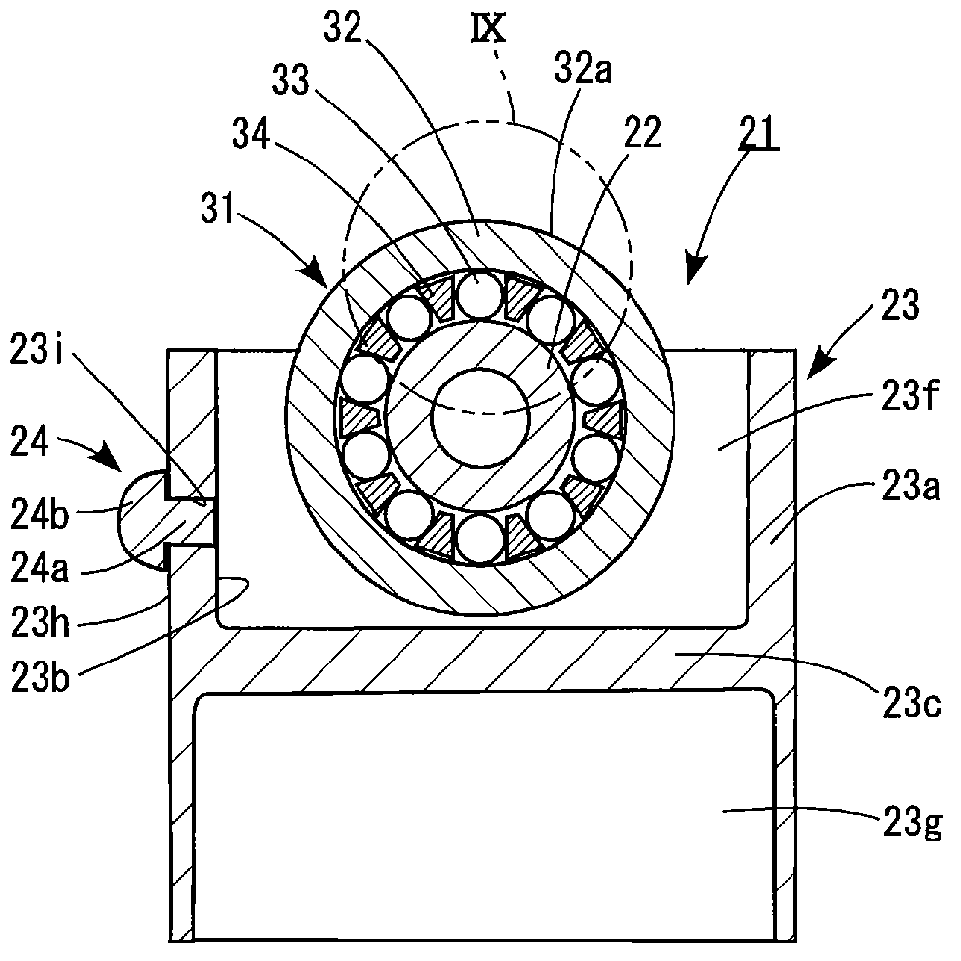

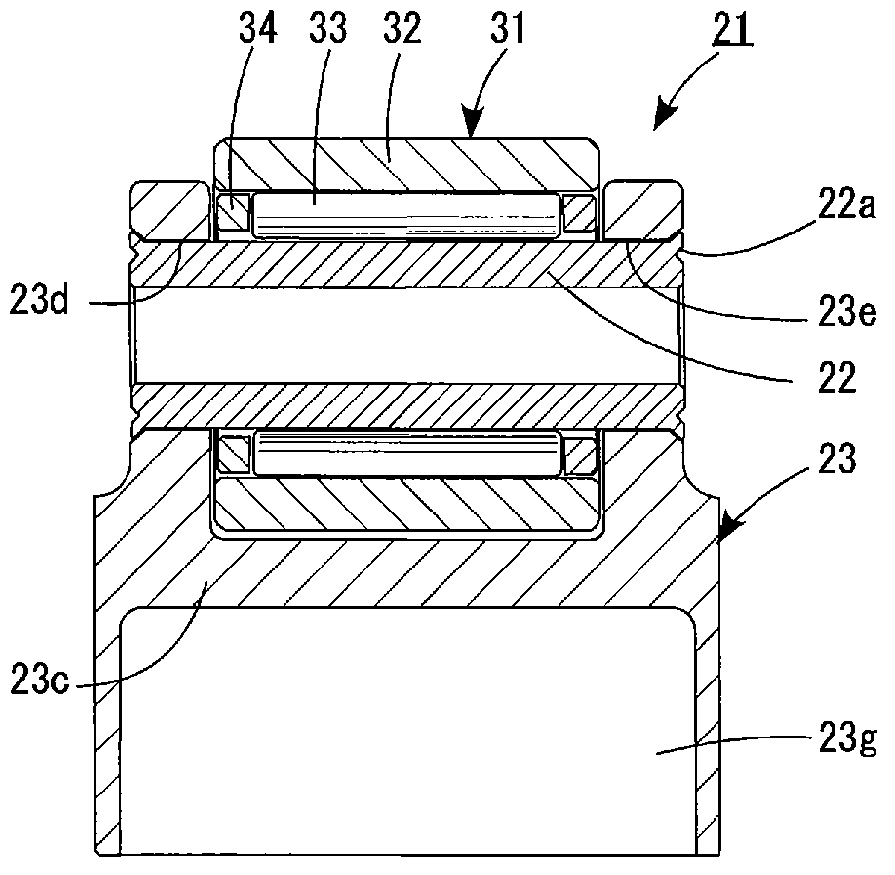

[0058] Hereinafter, embodiments of the present invention will be described based on the drawings.

[0059] A high-pressure pump 11 provided with a tappet according to an embodiment of the present invention includes a camshaft 12 provided with a cam 12a on the outer diameter side and figure 1 Rotational movement in the direction of the arrow A in the middle; the tappet 21, which abuts against the cam 12a and converts the rotational movement of the camshaft 12 into a reciprocating linear motion and transmits it to the pump plunger 13 (hereinafter referred to as "the plunger") and Carry out reciprocating linear motion; the plunger 13 as a rod-shaped component, which abuts against the tappet 21 to perform reciprocating linear motion; a high-pressure chamber (not shown in the figure), which feeds fuel according to the reciprocating linear motion of the plunger 13 to make it high-pressure; The spring 14 is provided so as to be in contact with the tappet 21 and the plunger 13 is dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com