Double-station heater for thermoplastic material

A technology of thermoplastic materials and heaters, applied in the field of double-station heaters, can solve the problems of low utilization rate of heat energy of heaters, low production efficiency, increase of production cost and production cycle, and achieve wide application range, high production efficiency, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

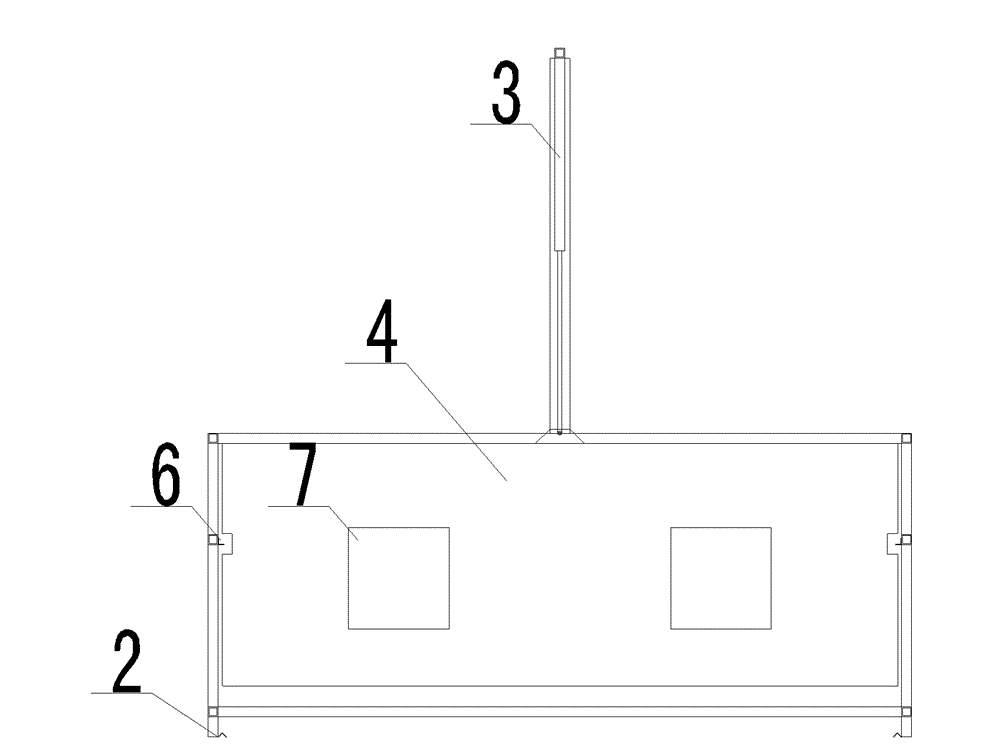

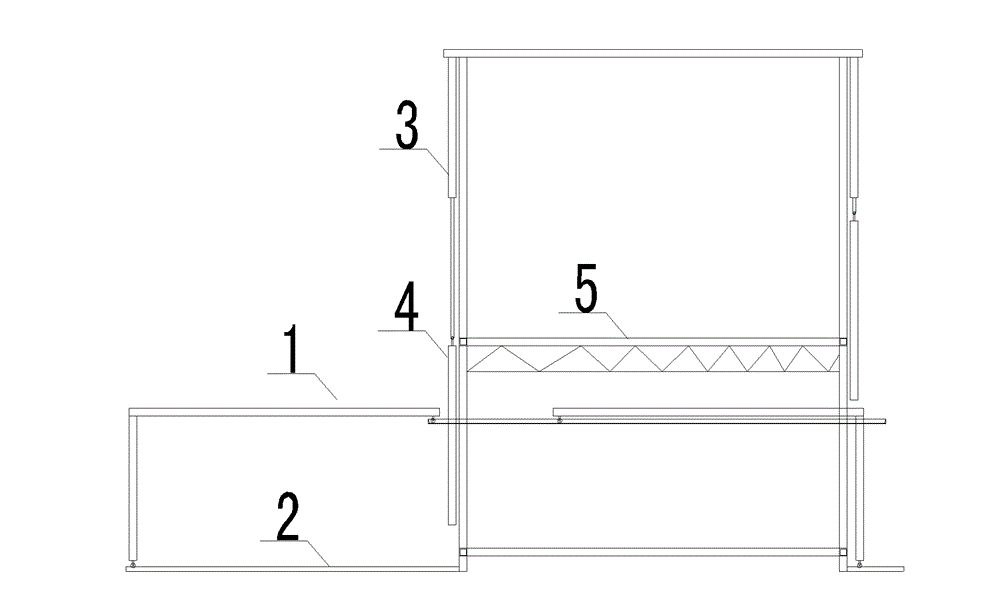

[0021] Such as figure 1 , figure 2 As shown, a dual-station heater for thermoplastic materials includes a workpiece placement frame assembly, a stretch door assembly, a heater body 5, and a heater body guide rail 6. The heater body 5 and the heater body The guide rail 6 is slidably connected, and there are two sets of the workpiece placing frame assembly and the drawing door assembly, and the two sets of drawing door assemblies are arranged at both ends of the heater body 5, and the two sets of workpiece placing One set of workpiece placement rack assembly in the rack assembly is arranged outside the heater body 5, and the other set of workpiece placement rack assembly is arranged inside the heater body 5;

[0022] When a set of workpiece placement frame assembly is loaded with thermoplastic material and heated in the heater body 5, another set of workpiece placement frame assembly performs the charging process outside the heater body 5, when the workpiece in the heater body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com