Printer, paper turning method of printer and system

A technology of printer and paper turning, applied in printing device, printing and other directions, can solve the problem of not knowing the direction of the front and back of the paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

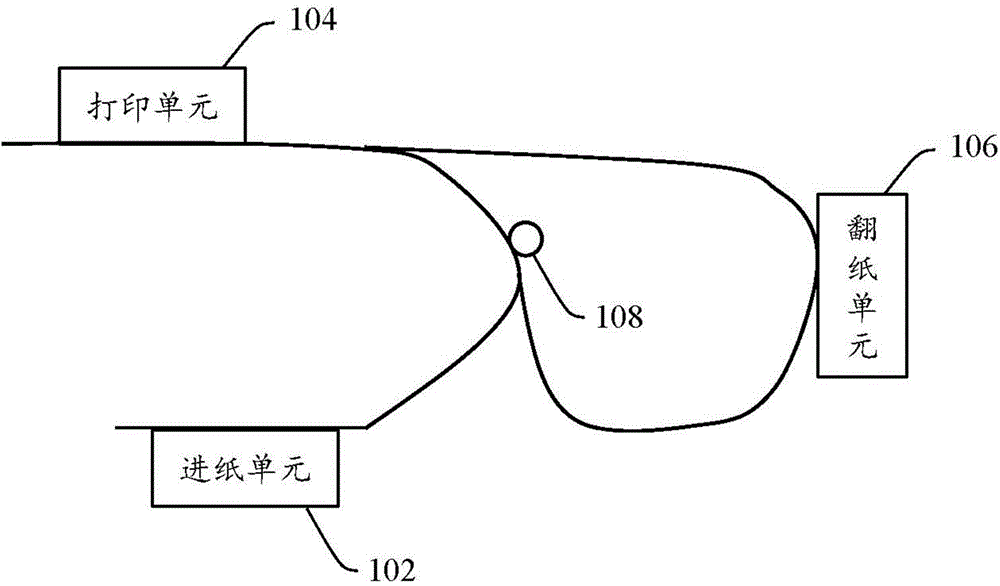

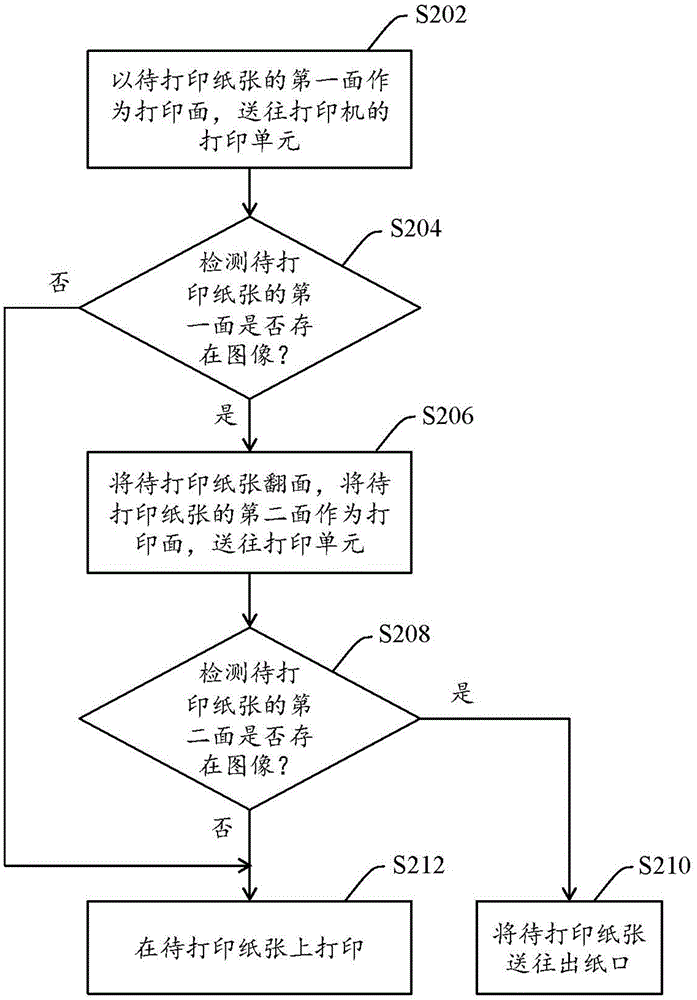

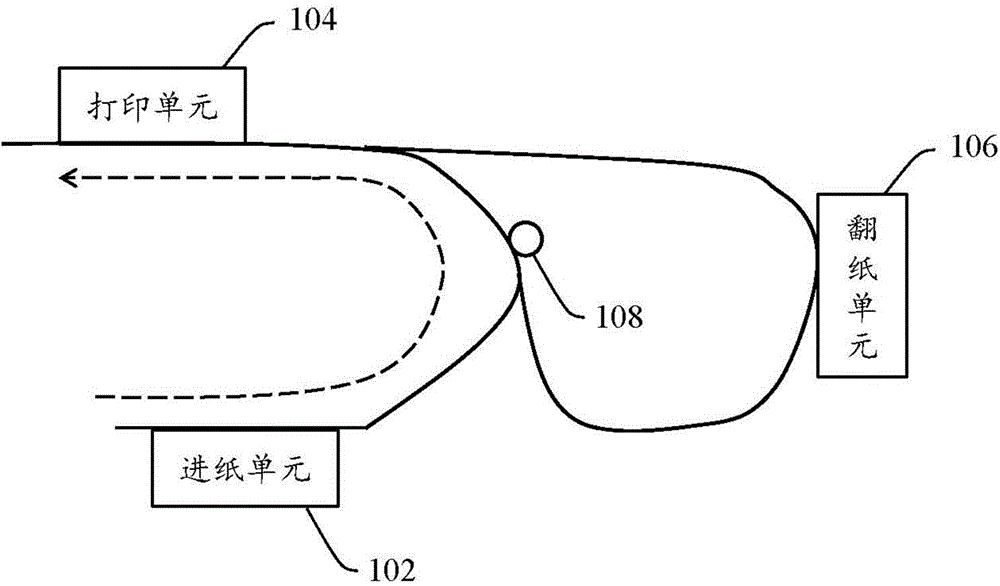

[0022] see figure 1 , the figure schematically shows the structure of a printer according to an embodiment of the present invention, the printer includes a paper feeding unit 102 , a printing unit 104 , a paper turning unit 106 and an image sensing unit 108 . The paper feeding unit 102 is used to take a piece of paper to be printed from the paper storage box, and the roller with a certain frictional force is in contact with the paper to be printed and rotated, so that the paper to be printed is transported from the paper storage box to the printing unit 104. print area. In this embodiment, the paper-turning unit 106 is a paper-turning mechanism with a back-type structure. The rollers with a certain frictional force are in contact with the paper to be printed and rotated, so that the paper to be printed on the surface of the paper-turning unit 106 Go around a circle in the back-shaped structure to achieve the effect of turning over. The printing unit 104 has a printing head f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com