Aluminum foil paper short edge rotary folder tool

A folding device and aluminum foil paper technology, which is applied in the direction of wrapping paper bending device, packaging, packaging cigarettes, etc., can solve the time-consuming and labor-intensive, difficult adjustment of the folding block near the edge of the aluminum paper and the center of rotation, and the failure to meet the adjustment requirements, etc. problems, to achieve the effect of improving maintenance efficiency, ensuring maintenance quality, and solving adjustment difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

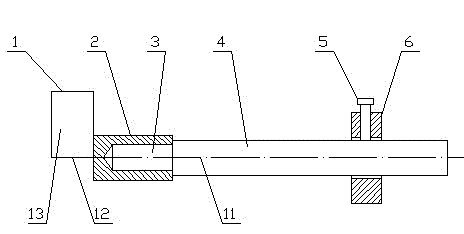

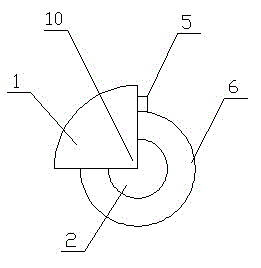

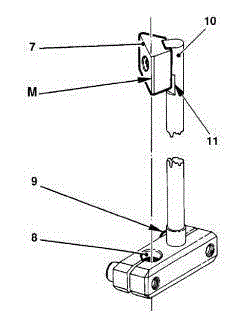

[0015] Depend on figure 1 with figure 2 The shown tooling of a short side rotary folder of aluminum foil includes a vertical tooling shaft 4, the tooling shaft 4 is a stepped shaft, and the top shaft body part of the tooling shaft 4 is the installation shaft section 3 constituting the stepped shaft, and the installation shaft section The diameter of 3 is smaller than the diameter of the shaft body of the tooling shaft 4 on the lower side, and the top of the tooling shaft 4 is hinged with the reference module 1 through the connector 2 .

[0016] The connecting piece 2 is in the shape of a short cylinder. The bottom surface of the connecting piece 2 is provided with a shaft hole matching the installation shaft section 3. The shaft hole can be a through hole or a blind hole. The connecting piece 2 and the tooling shaft 4 are coaxially arranged. , the connecting piece 2 is sleeved on the installation shaft section 3 through its shaft hole, and the reference module 1 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com