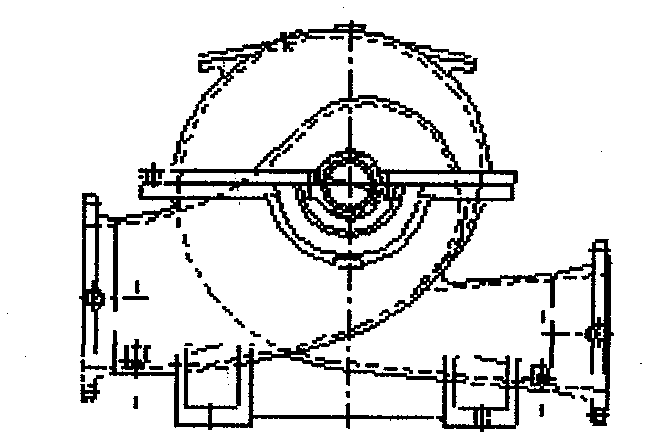

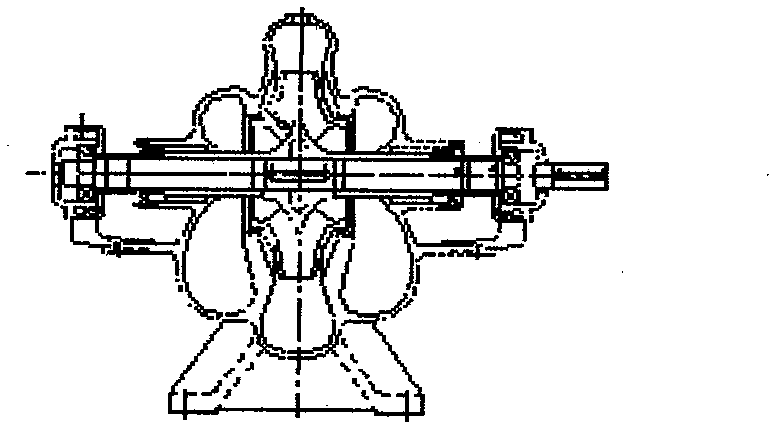

Centrifugal pump formed in double-suction volute chamber

A centrifugal pump and volute chamber technology, which is applied in the field of double-suction volute centrifugal pumps, can solve the problems of easily generating radial force and radial force cannot be eliminated, so as to eliminate radial force, improve efficiency, and reduce pump body Vibration and noise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

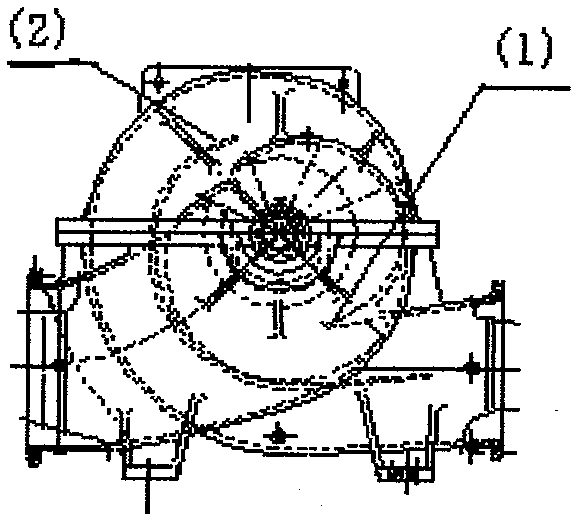

[0011] Such as Figure 5 Shown, described a kind of double-suction volute chamber split centrifugal pump presses out chamber hydraulic diagram according to the following steps:

[0012] (1) According to the design parameters of the water pump, calculate the cross-sectional dimensions of (1~8) of the flow channel.

[0013] (2) Calculate and determine the position of the tongue (1) according to the ratio of rotation.

[0014] (3) Another tongue (2) is set at a position 180° away from the tongue (1) and at a position where the circumference radius is equal.

[0015] (4) Make (1-4) cross-sectional views from the tongue (1) respectively.

[0016] (5) start to make (5~8) cross-sectional diagrams from the tongue (2), these sections are both inner and outer double runners, and all design parameters of the inner runners will be exactly the same as those corresponding to the 180° angle. The net cross-sectional area of the outer flow channel is equal to the calculated (5-8) cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com