Floating caliper disc center brake with automatic return mechanism

An automatic return and brake technology, which is applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of increasing parking brake clearance, failure, and inability to overcome mechanical friction and torque, so as to eliminate Eccentric wear and drag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and examples.

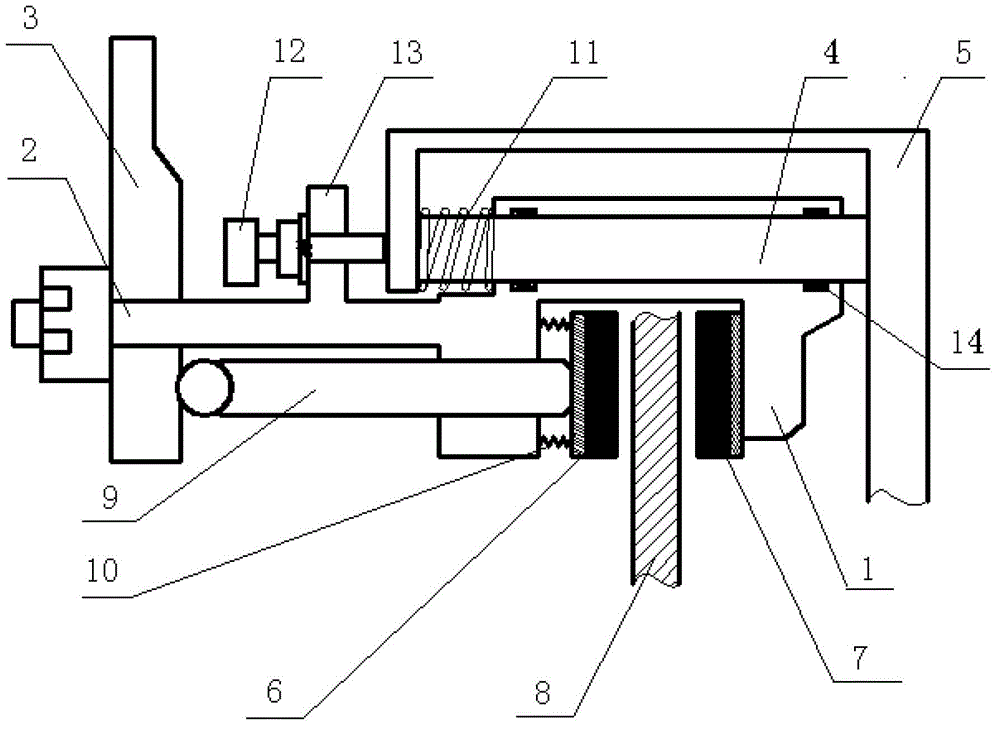

[0012] figure 1 It is a structural schematic diagram of the present invention: the floating caliper disc central brake with an automatic return mechanism of the present invention includes a central brake caliper body 1, a rocker shaft 2 and a rocker arm 3 connected to the central brake caliper body 1, passing through the central brake The sliding pin 4 of the caliper body 1, the sliding pin bracket 5, the front brake shoe 6 and the rear brake shoe 7 installed on the central brake caliper body 1, are located at the front brake shoe 6 and the rear brake shoe 7 Between the central brake disc 8, the brake ejector pin assembly 9, the front friction block return spring 10, and the sliding pin 4 between the rear end of the central brake caliper body 1 and the sliding pin bracket 5 is covered with a compression spring 11. A limit plate 13 protrudes from the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com