EVA (ethylene vinyl acetate) based PTC (phenylthiocarbamide) composite material, lithium battery anode and lithium battery

A technology of composite materials and lithium batteries, which is applied in the field of electrochemistry, can solve problems such as incomplete protection, remote components, and lagging safety protection of lithium-ion batteries, so as to prevent thermal runaway, improve safety performance, and reduce heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation of EVA base PTC composite material comprises steps:

[0044] Using petroleum ether as a solvent, put PEO, acetylene black, and EVA260 in a condensing reflux device in proportion to stirring for 5 h at 105 °C to obtain an EVA-based PTC composite material slurry, which was then dried to obtain an EVA-based PTC composite material. The mass percent contents of PEO, acetylene black and EVA260 were 1%, 16% and 83% respectively.

[0045] Adopt following method to measure the temperature resistance characteristic of present embodiment EVA base PTC composite material:

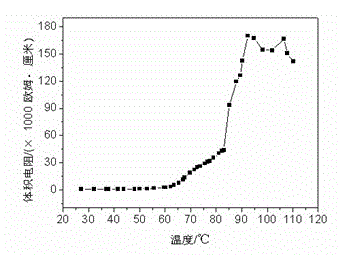

[0046] Put the EVA-based PTC composite material slurry into a mold to dry, cut into sheets with a length of 10mm, a width of 10mm, and a thickness of 0.4mm, measure its resistance at different temperatures, and obtain the change curve of its resistance with temperature, see figure 1 . It can be seen from the figure that the resistivity of the sample begins to rise rapidly at 62 °C, and the resis...

Embodiment 2

[0049] The preparation of EVA base PTC composite material comprises steps:

[0050] Using petroleum ether as a solvent, put PEO, acetylene black, and EVA260 in a condensing reflux device in proportion to stirring for 5 h at 105 °C to obtain an EVA-based PTC composite material slurry, which was then dried to obtain an EVA-based PTC composite material. The mass percent contents of PEO, acetylene black and EVA260 are 10%, 30% and 60% respectively.

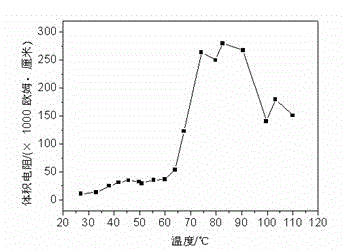

[0051] Adopt the method identical with embodiment 1 to test the temperature resistance characteristic of the present embodiment EVA base PTC composite material, the result sees figure 2 , it can be seen from the figure that the EVA-based PTC composite material in this example has a positive temperature coefficient characteristic, and its Curie temperature is about 90 °C.

[0052]

Embodiment 3

[0054] The preparation of EVA base PTC composite material comprises steps:

[0055] Using petroleum ether as a solvent, put PEO, acetylene black, and EVA260 in a condensing reflux device in proportion to stirring for 5 h at 105 °C to obtain an EVA-based PTC composite material slurry, which was then dried to obtain an EVA-based PTC composite material. The mass percentage contents of PEO, acetylene black and EVA260 are 10%, 10% and 80% respectively.

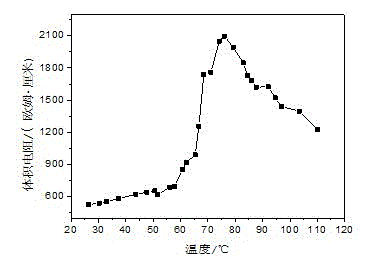

[0056] Adopt the method identical with embodiment 1 to test the temperature resistance characteristic of the present embodiment EVA base PTC composite material, the result sees image 3 , it can be seen from the figure that the EVA-based PTC composite material in this example has a positive temperature coefficient characteristic, and its Curie temperature is about 80 °C.

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com