Button latch with integrally molded cantilever springs

A push-button, cantilevered technology for push-button latches with one-piece molded cantilever springs, which solves the problem of expensive manufacturers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

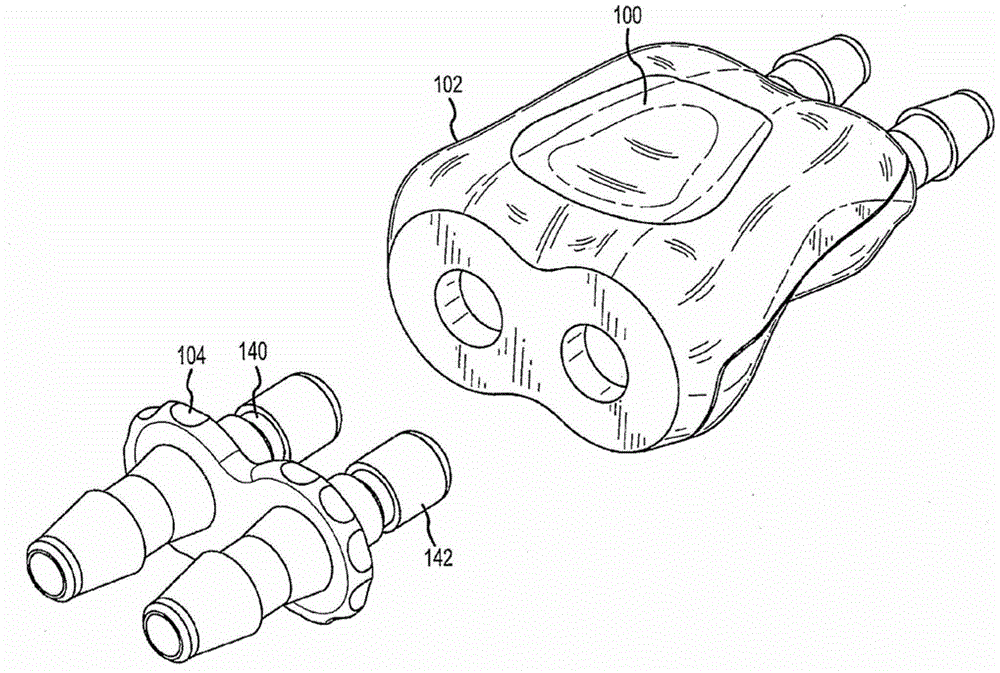

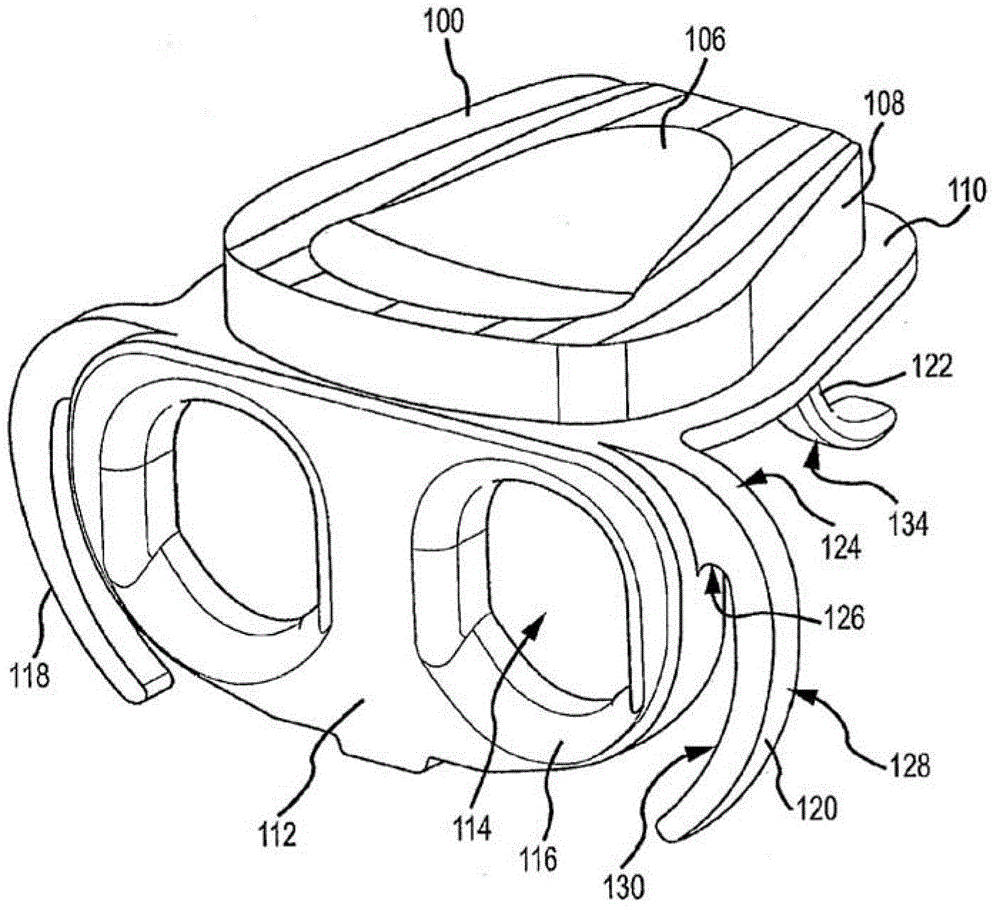

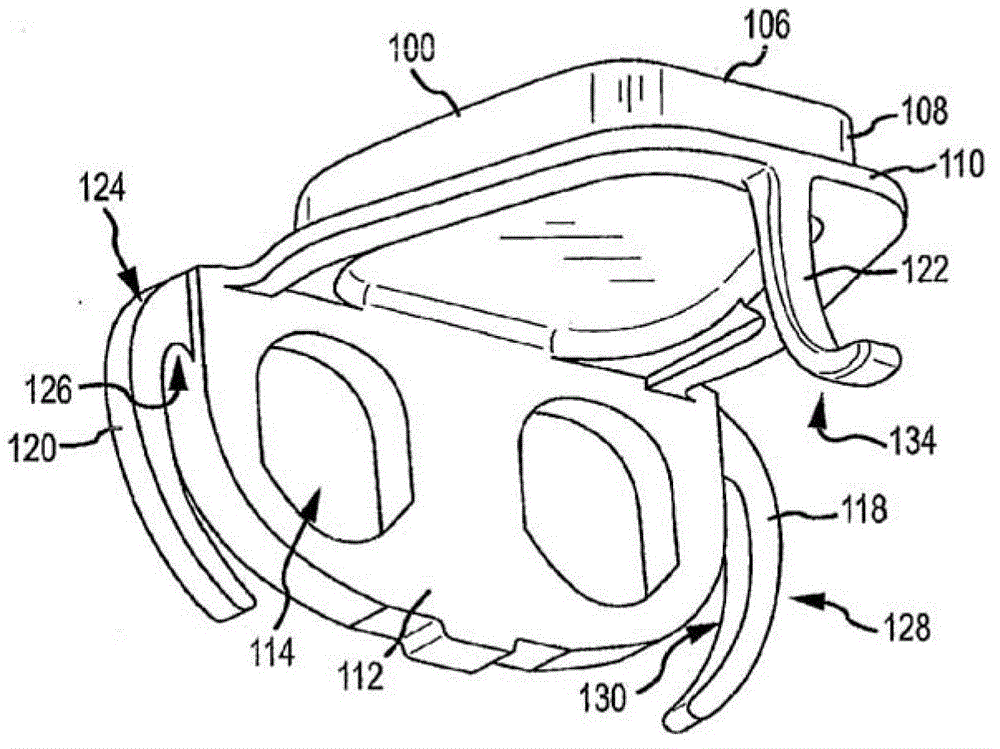

[0036] Female fluid connectors can be used with male bayonet connectors to releasably connect tubing segments. In one embodiment, such as Figure 1-2C As shown, the female receiving connector 102 includes a button latch 100 that actuates an integral, blade-style latch plate 112 . Latch plate 112 physically secures male bayonet connector 104 within female connector 102 . When the male bayonet connector 104 is inserted distally into the female receiving connector 102, the distal end of the male bayonet connector 104 abuts the proximal edge of the receiving aperture 114 in the latch plate 112 to downwardly The latch plate 112 is biased and lowers the receiving aperture 114 through which the male bayonet connector 104 can pass. By arranging cantilever springs 118, 120, 122 (see Figures 2A-2C) against the downward travel of the latch plate 112 to bias the latch plate 112 in the upward locked position, the cantilevered springs 118 , 120 and 122 extend from the button actuator 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com