Rotor for modulated pole machine

A technology for modulated pole motors and rotors, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as undesired deformation, strength problems, complexity of individual components and increased cost, and achieve low-cost geometric structure, easy The effect of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] In the following description, reference is made to the accompanying drawings, which show by way of example how the invention may be practiced.

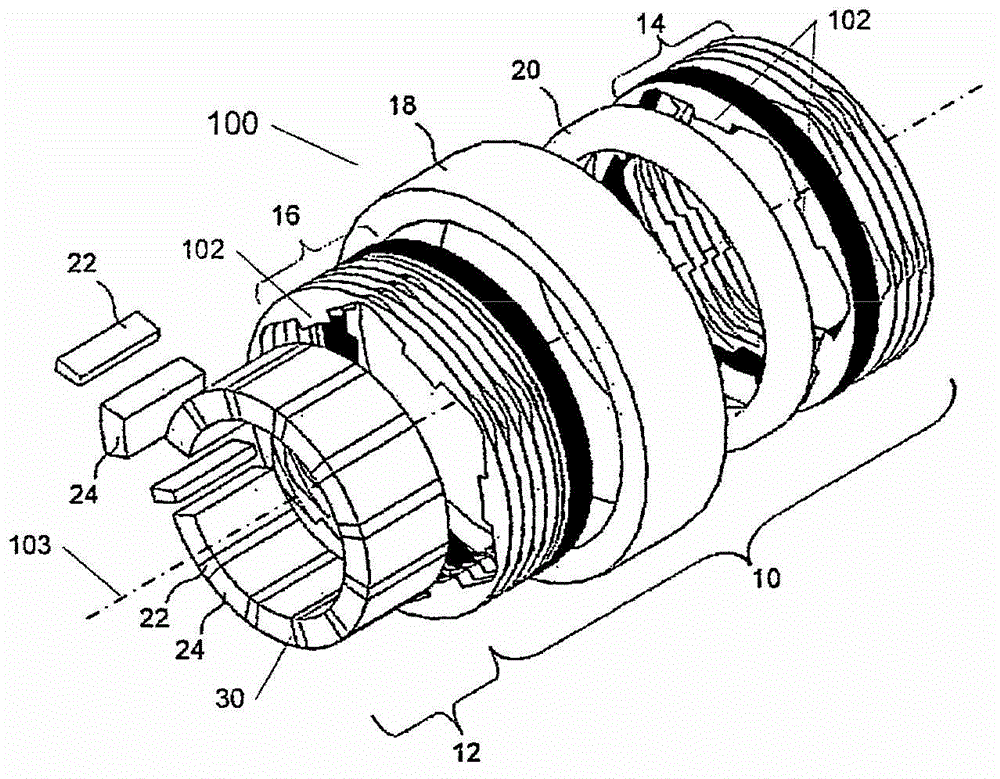

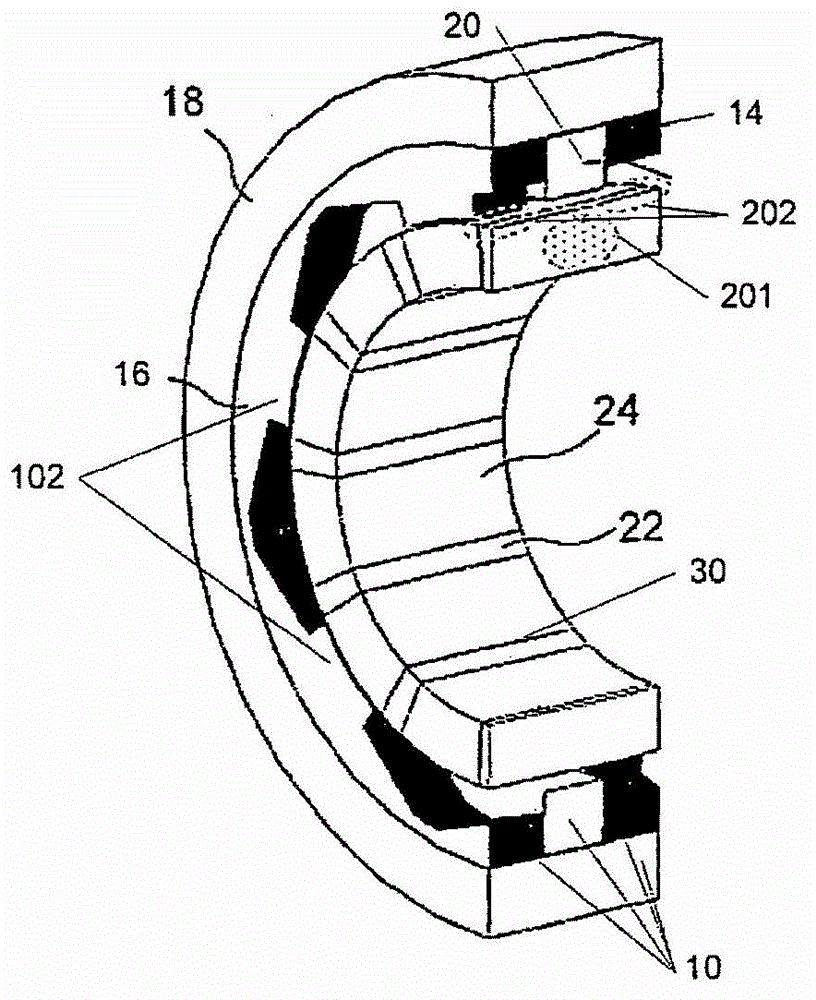

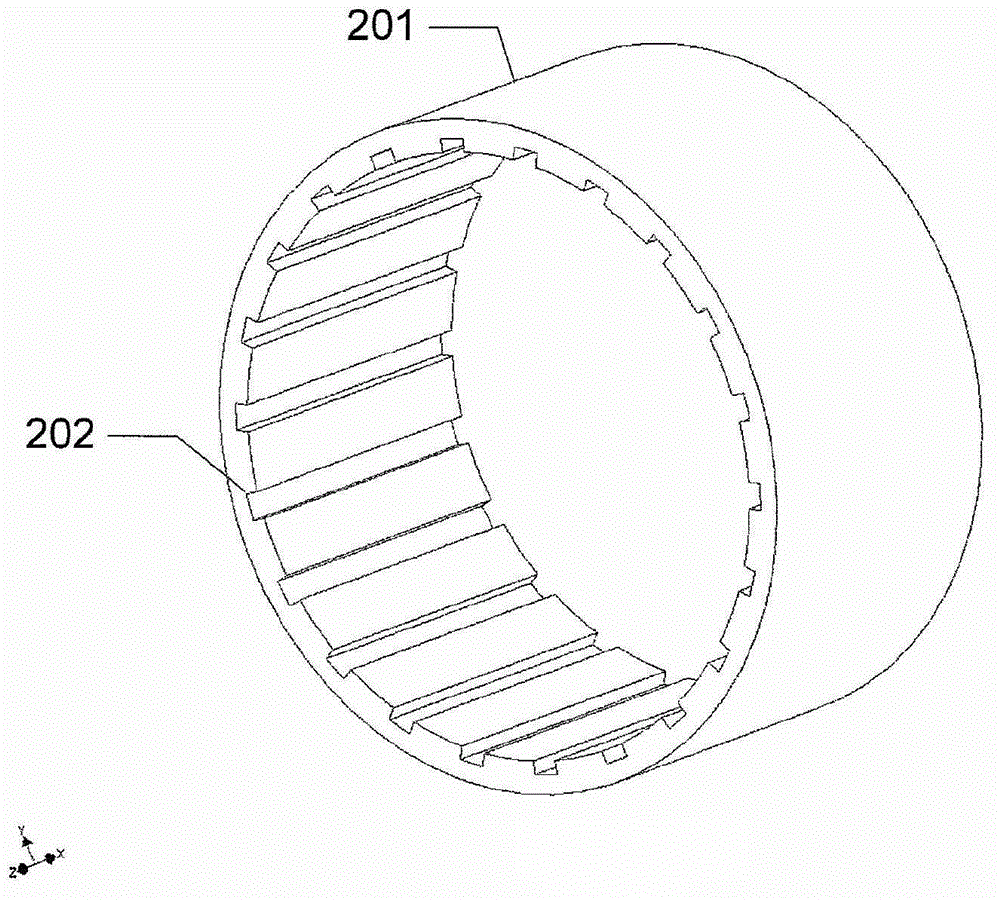

[0087] The invention relates to the field of modulated pole electric machines 100, an example of which is shown in a schematic exploded perspective view in Fig. 1a. The stator 10 of the modulated pole machine is basically characterized by the use of a central single winding 20 magnetically feeding a plurality of teeth 102 formed in a soft magnetic core structure. The stator core is then formed around windings 20 which, for other common motor configurations, are formed around individual tooth core sections. Examples of modulated pole motor layouts are sometimes referred to as claw pole, chicken claw, Rundle or TFM motors. More specifically, the illustrated modulated pole machine 100 includes two stator core sections 14, 16 (each section includes a plurality of teeth 102 and is substantially circular), A coil 20 arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com