A bolt tightening system capable of accurately positioning the axis of a screw hole

A technology for precise positioning and bolts, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as laboriousness, cost increase, bolt or screw hole damage, etc., to achieve reduced manufacturing costs, reliable working process, and strong versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

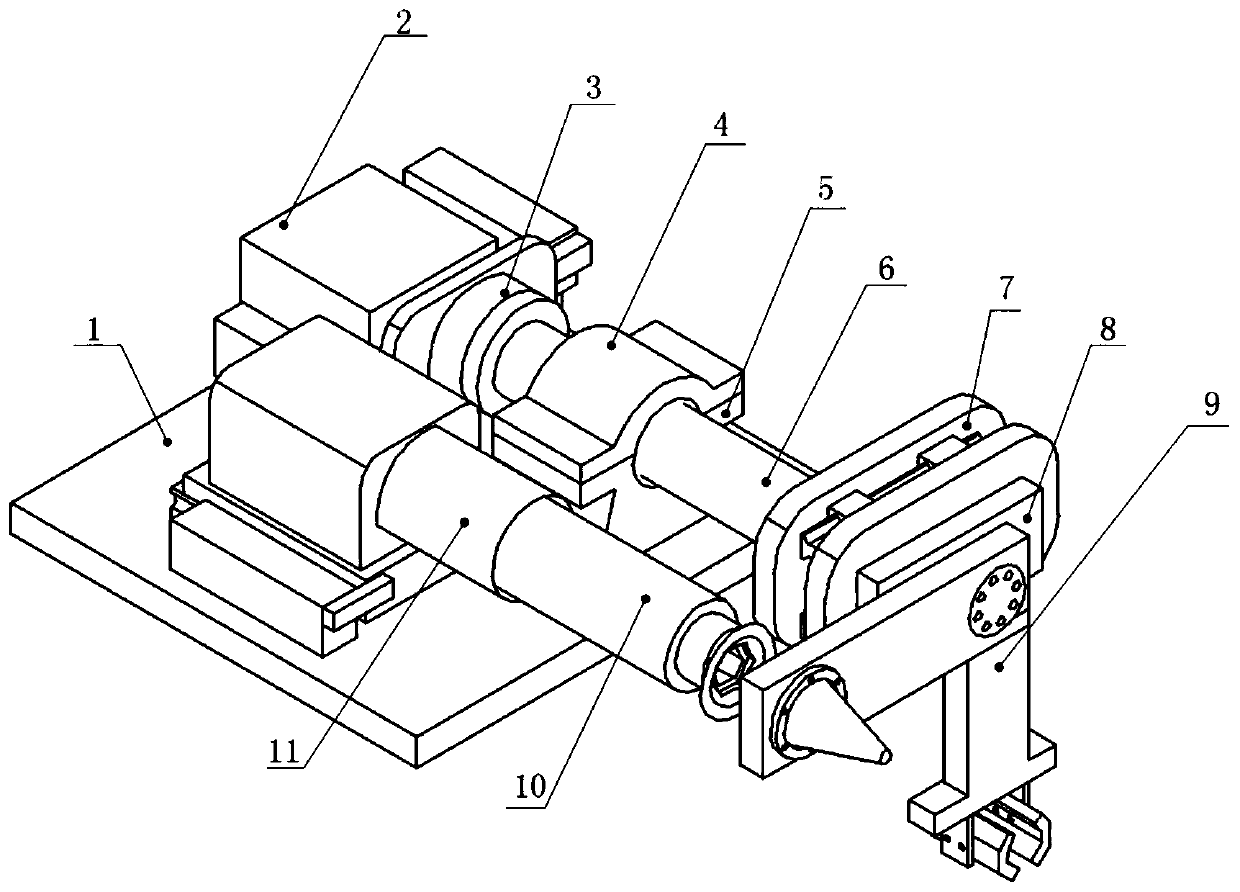

[0061] Such as figure 1 with figure 2 Shown: This embodiment discloses a bolt tightening system capable of accurately positioning the axis of a screw hole, which includes a rotating platform 9, a centering cone shaft 20, a bolt clamping device and a tightening device.

[0062] In detail, the rotating platform 9 is provided with a V-shaped rotating frame, and the V-shaped included angle of the V-shaped rotating frame is fixedly connected with the rotation center of the rotating platform 9.

[0063] The centering cone shaft 20 and the bolt clamping device are respectively arranged at the ends of the two arms of the V-shaped rotating frame, and the axis of the centering cone shaft 20 and the axis of the bolt clamped by the bolt clamping device The distances from the central axis of rotation are all equal.

[0064] The axis of the centering cone shaft 20, the axis of the bolt held by the bolt clamping device, and the rotation center axis are parallel to each other in space.

[0065] The ...

Embodiment 2

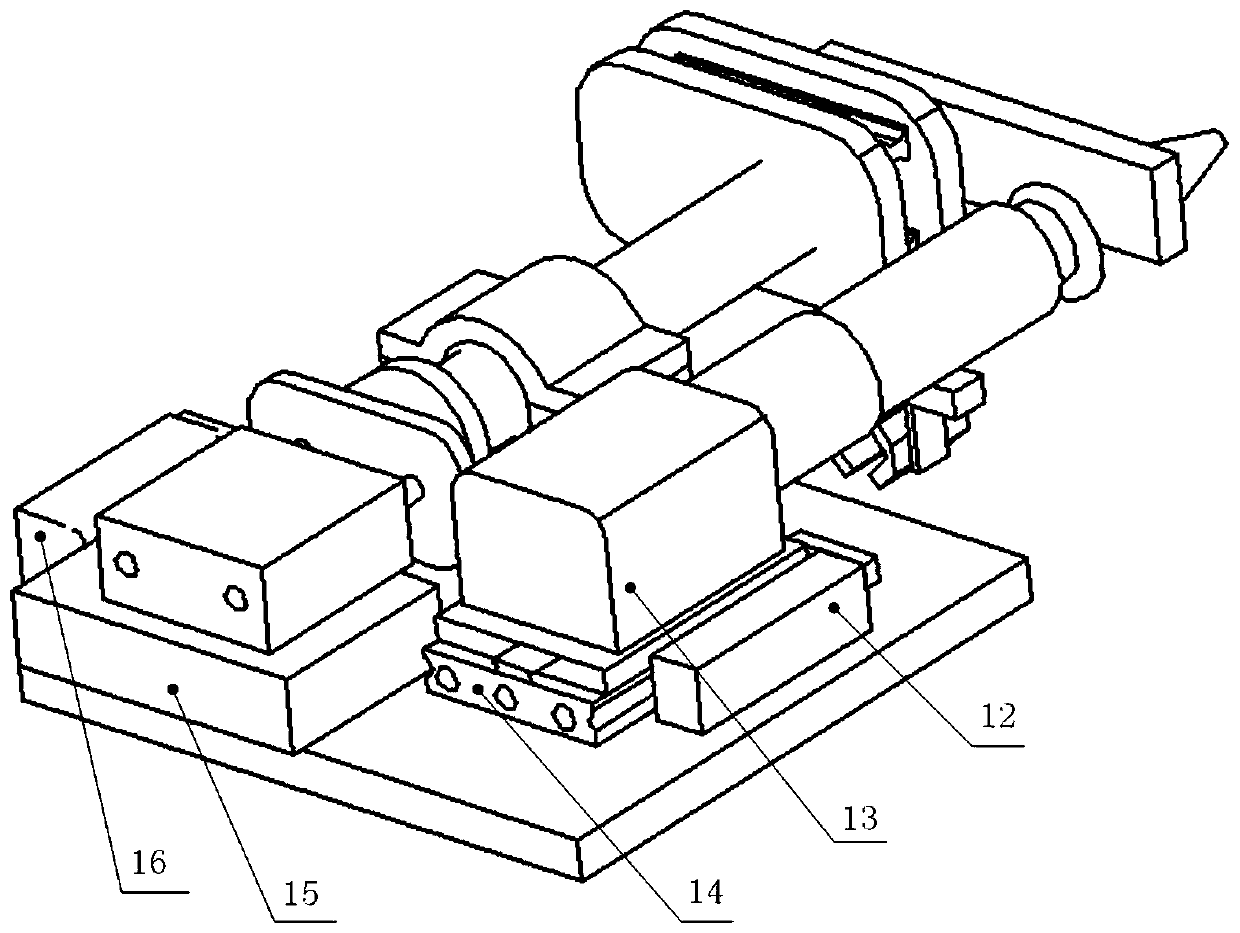

[0116] Combine figure 1 with figure 2 , The bolt tightening system capable of accurately positioning the axis of the screw hole of the present invention includes a bottom plate 1, a tightening device and a positioning device horizontally installed on the bottom plate, the tightening device and the positioning device are arranged in parallel left and right, and a rotating platform 9 is installed at the end of the positioning device. , The biaxial cylinder 2 provides the forward and backward feeding movement of the rotating platform 9 through the passive rotating shaft 6.

[0117] Such as figure 2 As shown, the bottom plate 1 is equipped with a tightening device, a biaxial cylinder 2 and a passive rotating assembly.

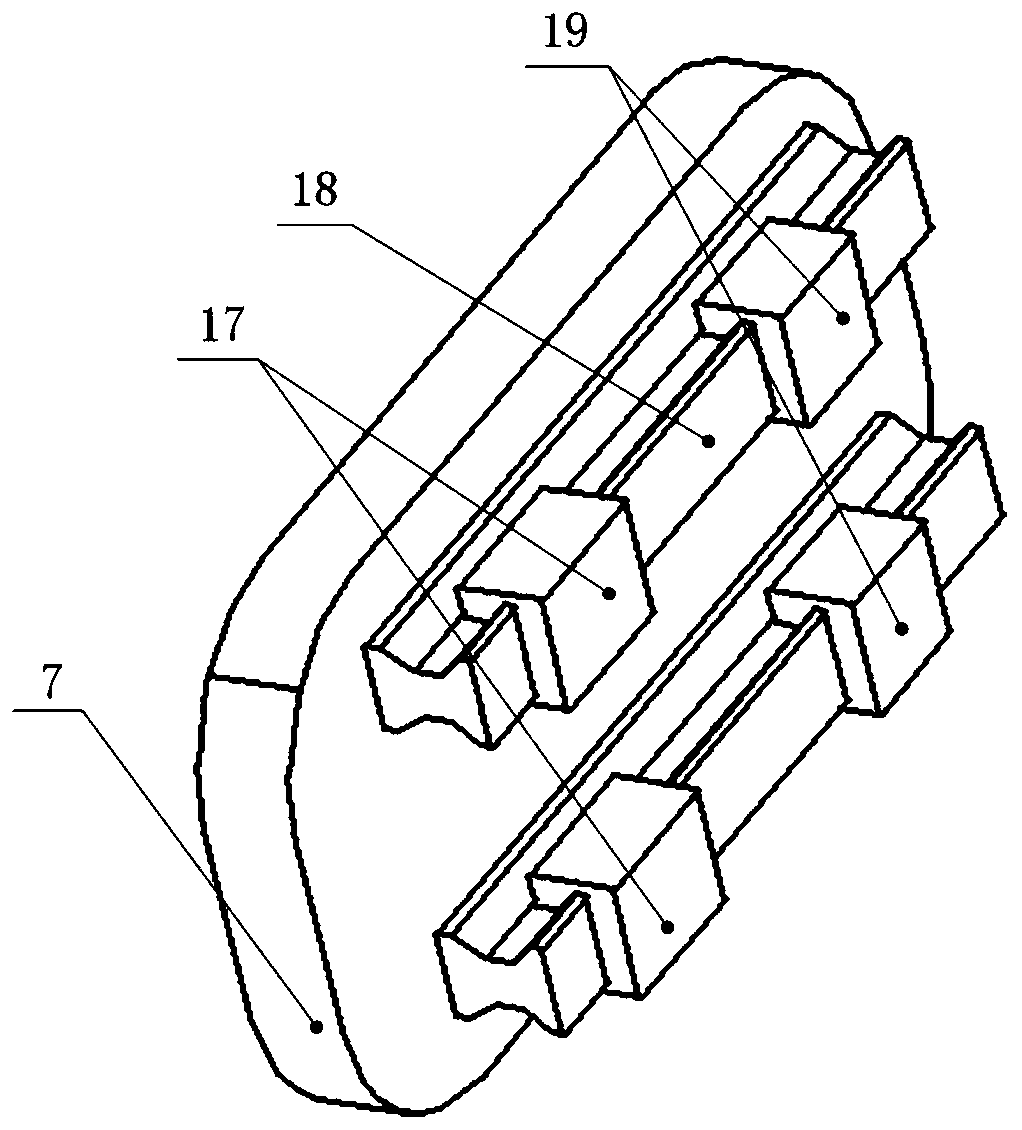

[0118] Combine figure 1 , figure 2 with Figure 5 The tightening device includes a passively compliant tightening assembly 10. The support sleeve 104 on the tightening assembly 10 is embedded with a telescopic spring 109 and a sliding bearing 105 to compensate for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com