Clamp type self-lock equipment

A self-locking device and clamp-type technology, used in seat belts, life-saving equipment and other directions, can solve the problem of insufficient self-locking effect and other problems, and achieve reliable self-locking effect and reliable self-locking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention are described in detail below:

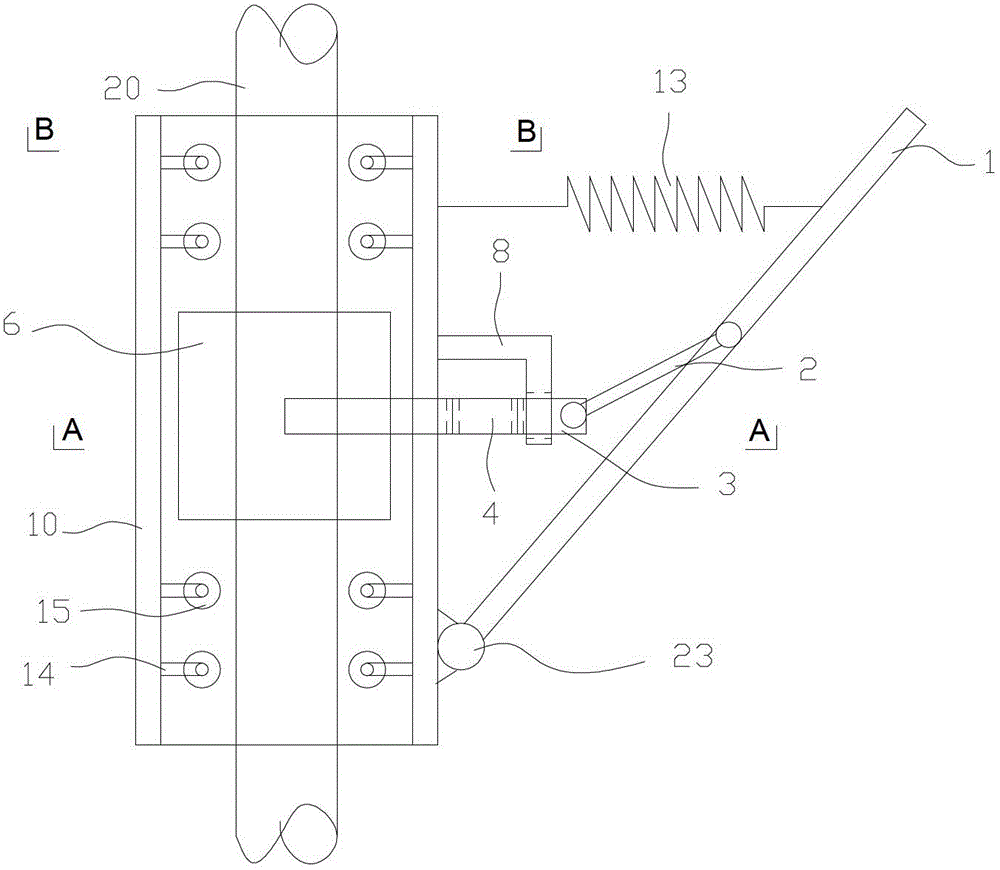

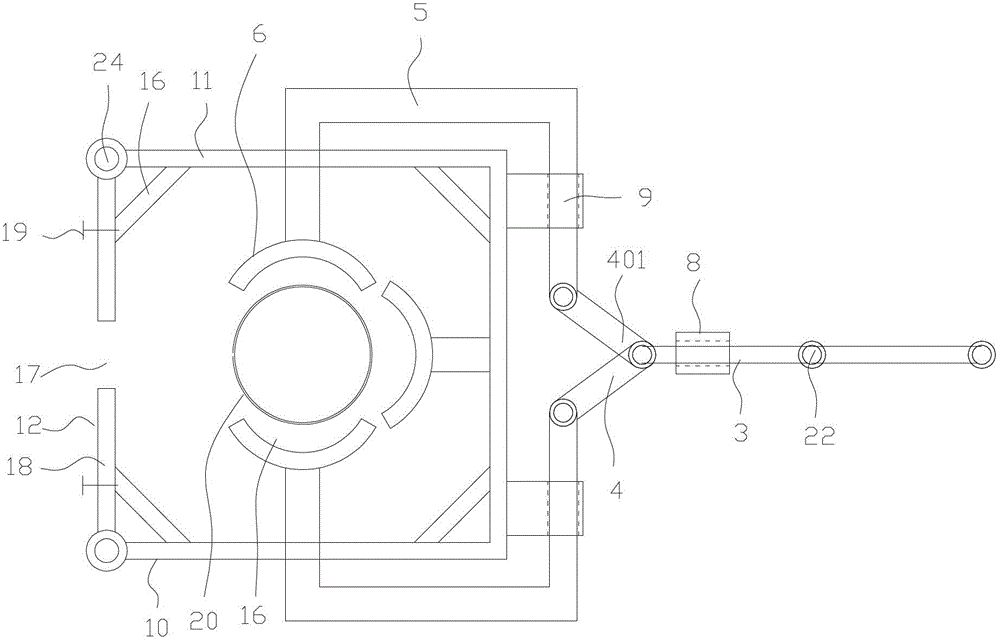

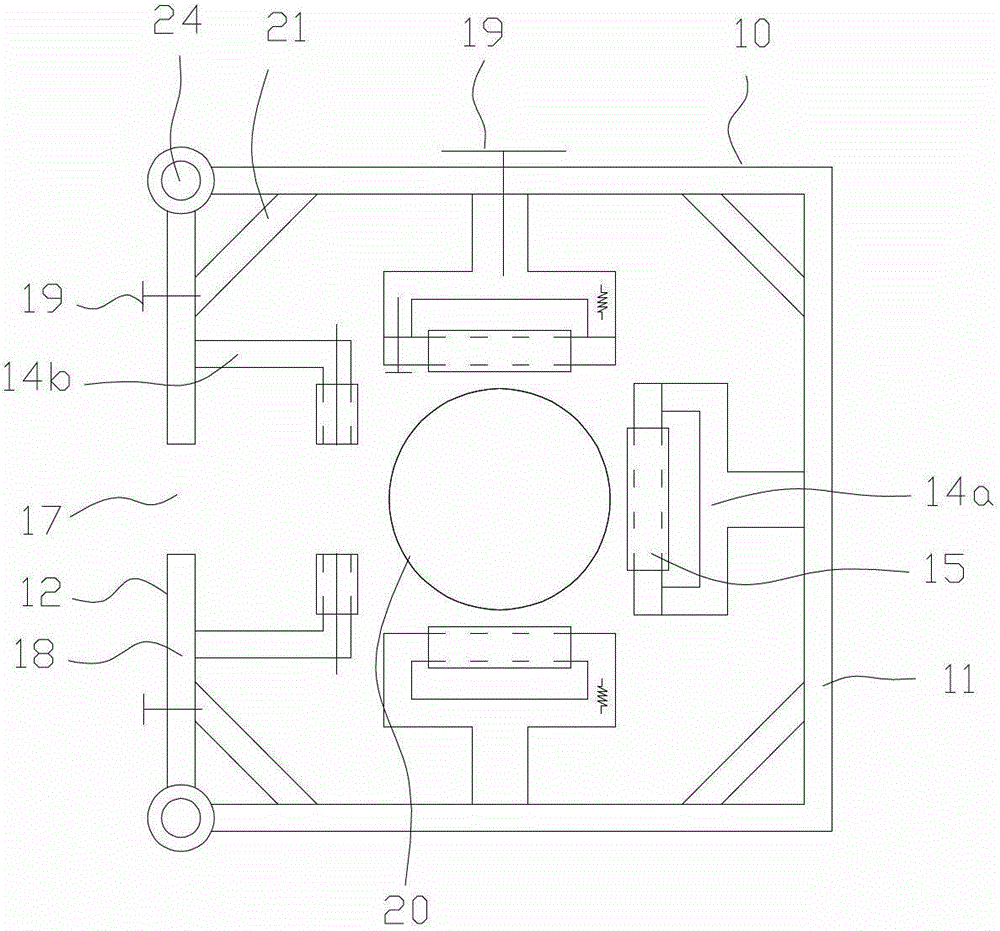

[0034] Such as Figure 1-2 As shown, a pincer type self-locking device includes a housing 10, a connecting rod transmission structure and a force component transmission structure. The housing 10 is provided with a fixed housing wall 11 and a movable housing wall 12. The rod transmission structure includes a rocker arm 1, a steering link 2, a horizontal link 3, a rocker shaft 23, a link shaft 22 and a horizontal sleeve 8. One end of the rocker arm 1 is movably connected to the On the outer wall of the fixed shell wall 11 opposite to the movable shell wall 12, one end of the steering link 2 is movably connected to the rocker arm 1, and the other end is connected to the first end of the horizontal link 3 through the link shaft 22. connection, the horizontal connecting rod 3 is covered with a horizontal sleeve 8, and the horizontal sleeve 8 is fixed on the outer wall of the fixed shell wall 11 opposite t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com