Pulper convenient to clean

A pulper, cleaning technology, applied in the field of papermaking, to achieve stable movement, improve the working environment, and good self-locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

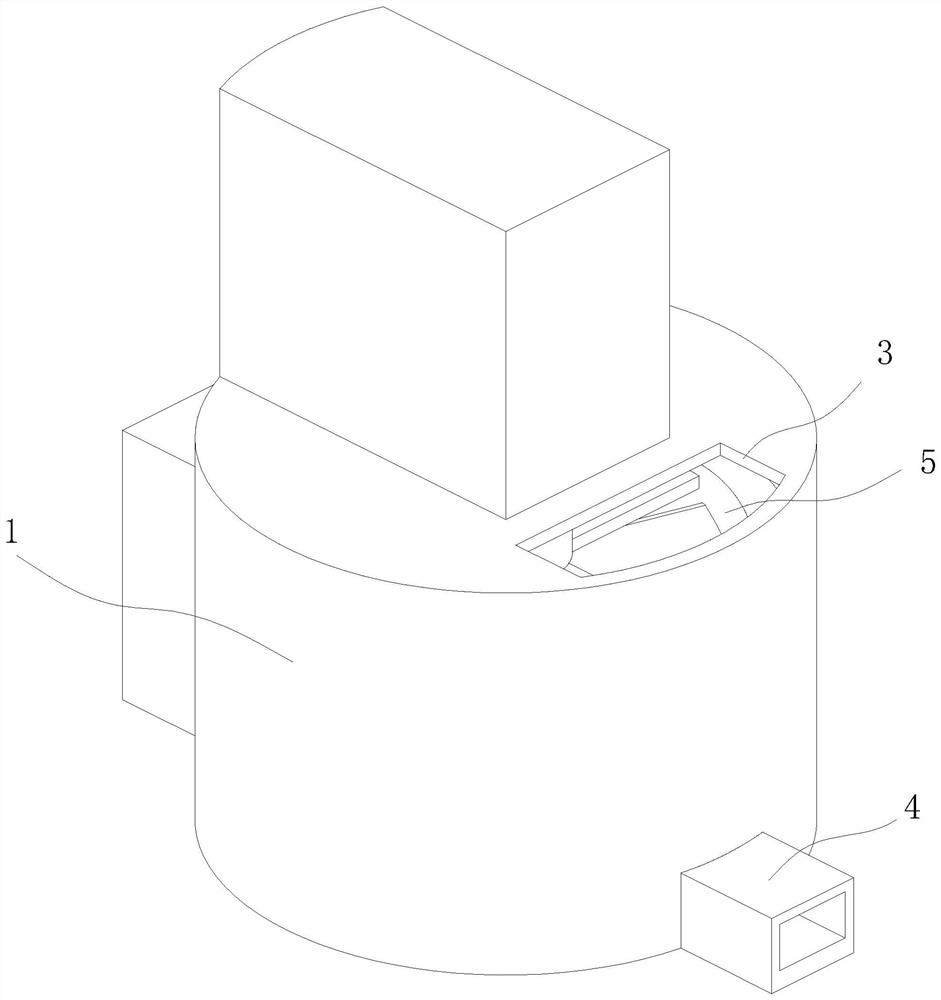

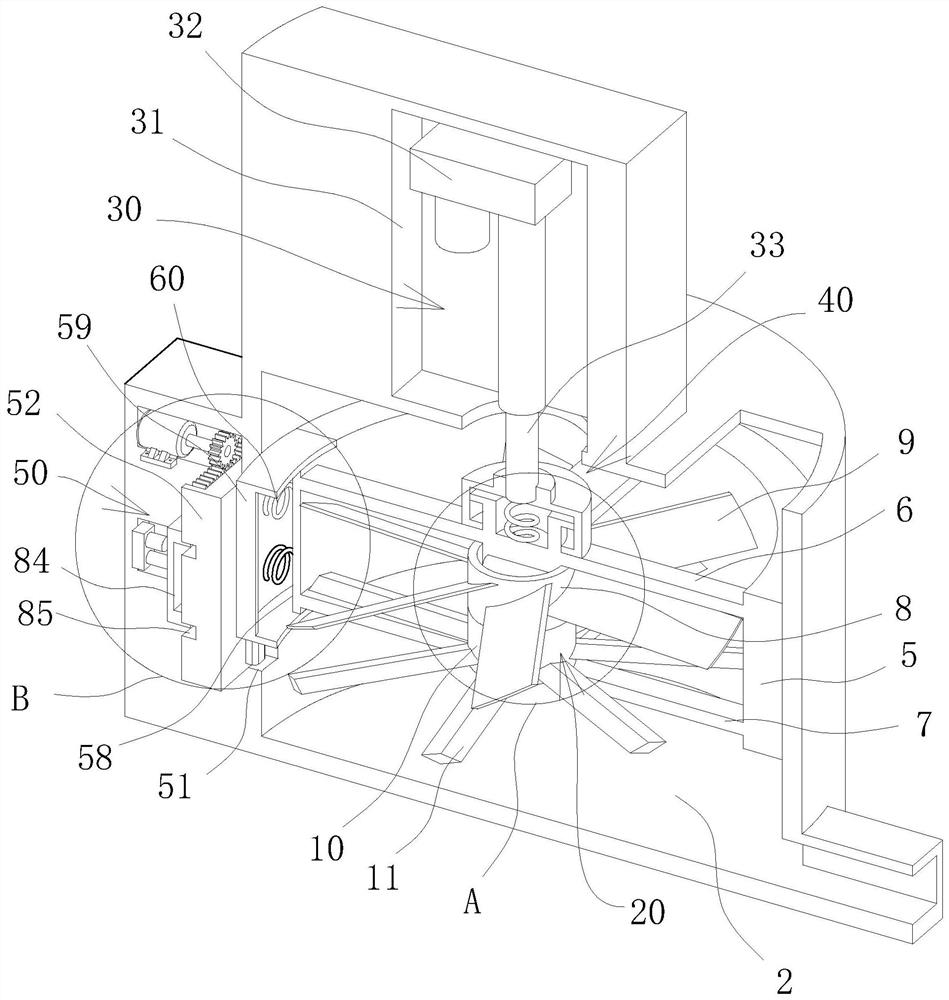

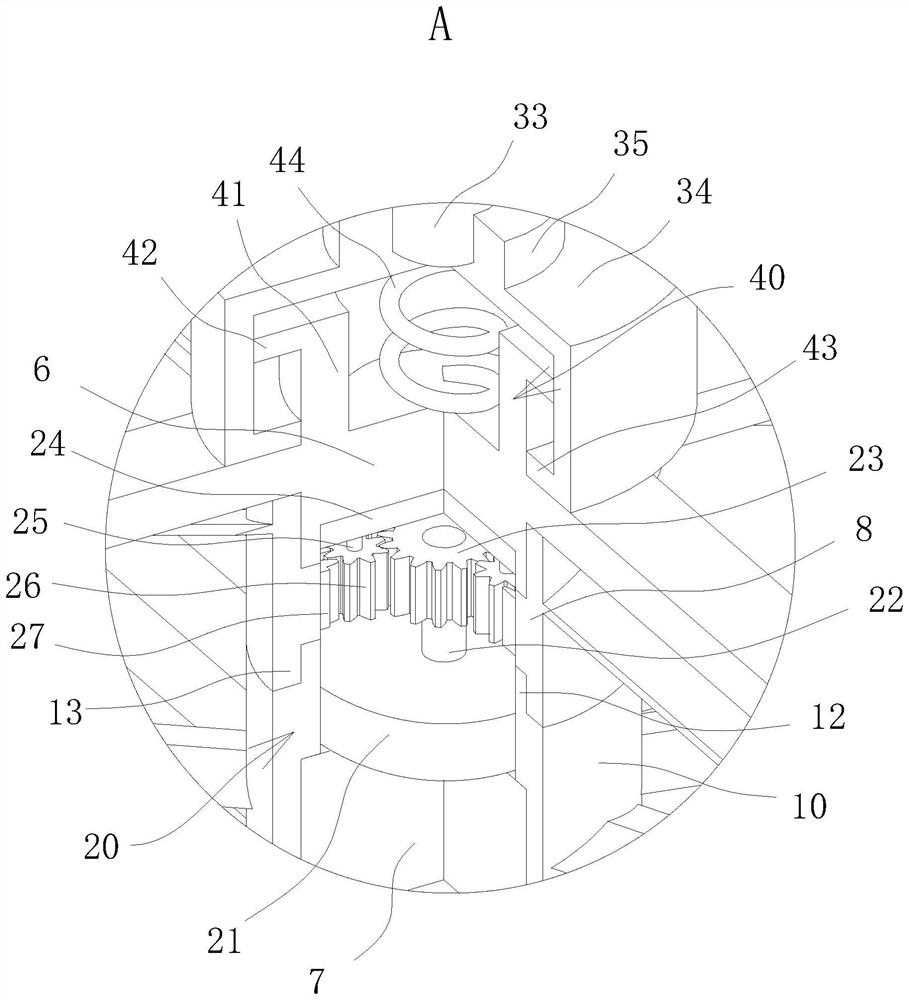

[0026] A pulper for easy cleaning, such as figure 1 , figure 2 and image 3 As shown, including the cabinet 1, the cabinet 1 is provided with a working chamber 2, the upper and lower ends of the cabinet 1 are respectively provided with a material inlet 3 and a pulp outlet pipe 4 connected to the working chamber 2, and a lifting frame 5 is slidably arranged in the working chamber 2 The upper and lower ends of the lifting frame 5 are respectively provided with a first support 6 and a second support 7, the first support 6 is rotatably connected with a first rotating frame 8, and the first rotating frame 8 is provided with six uniformly distributed blades 9, The second support 7 is rotatably connected with a second rotating frame 10, and the second rotating frame 10 is provided with seven evenly distributed cutting knives 11. The first rotating frame 8 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com