Cutting device for sugar cane harvesters

A technology for cutting devices and harvesters, applied in the direction of harvesters, cutters, applications, etc., can solve problems such as increased difficulty, time loss, and increased bolt risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

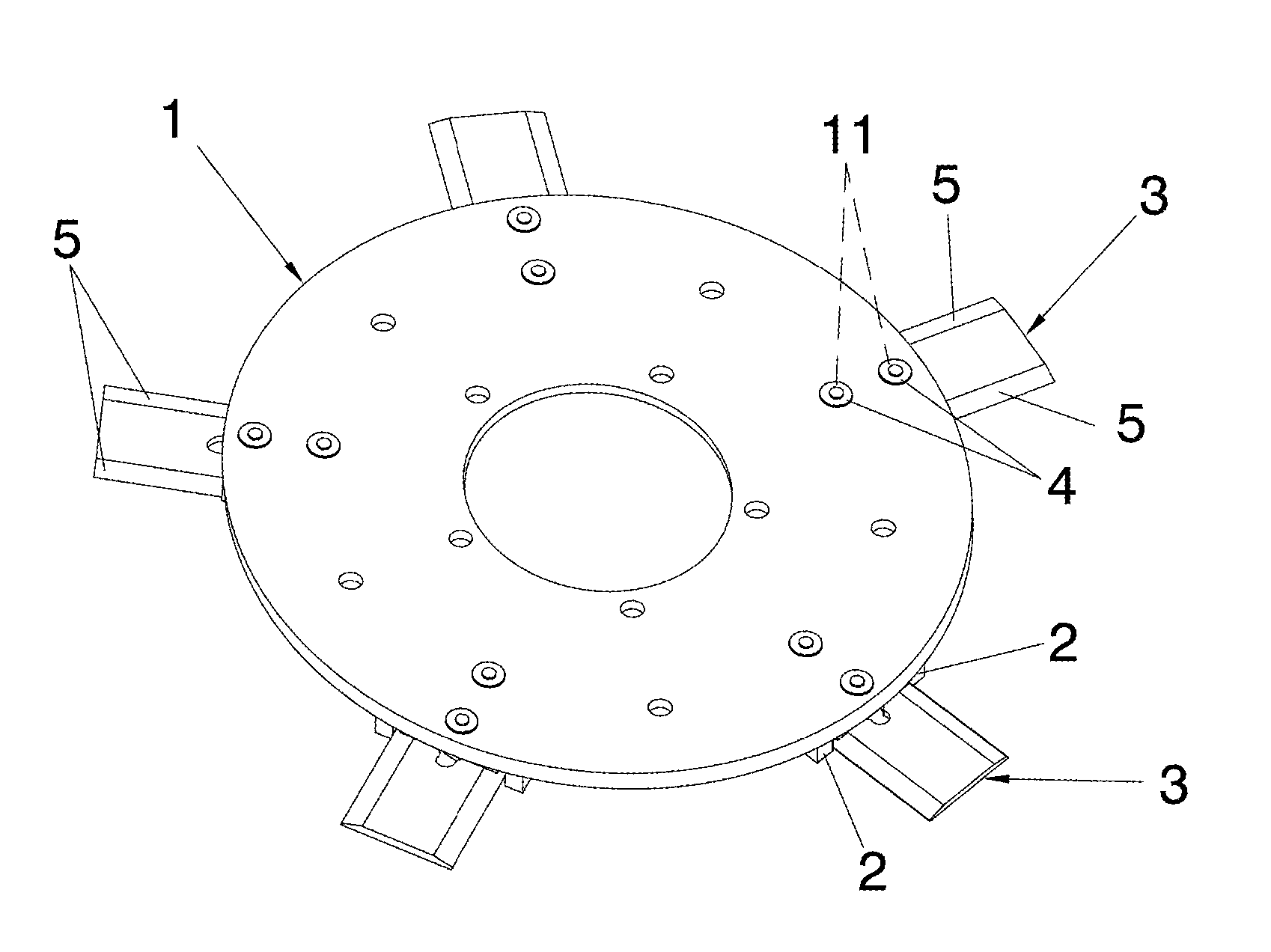

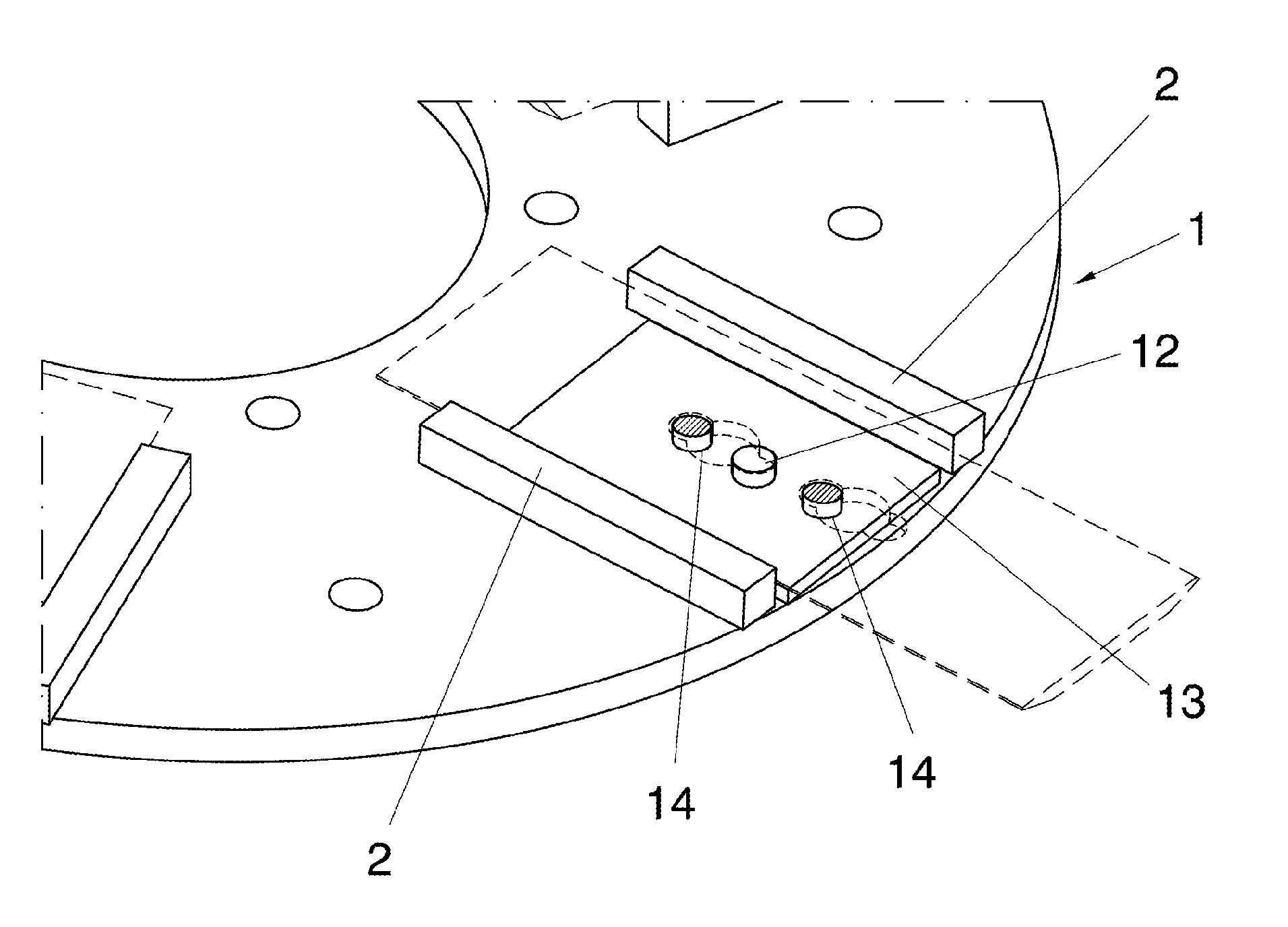

[0027] Considering the numbering adopted in the drawings, the cutting device for a sugarcane harvester comprises support discs 1 each comprising a pair of guides 2 on which radial blades 3 are arranged, coupled to screw holes by Fixing bolt 4 in 11 makes radial blade 3 be fixed on the support disc 1, and fixation bolt 4 is set up in the nut, and nut is contained in the support disc 1. The aforementioned screw holes can also be incorporated directly into the support disc 1 .

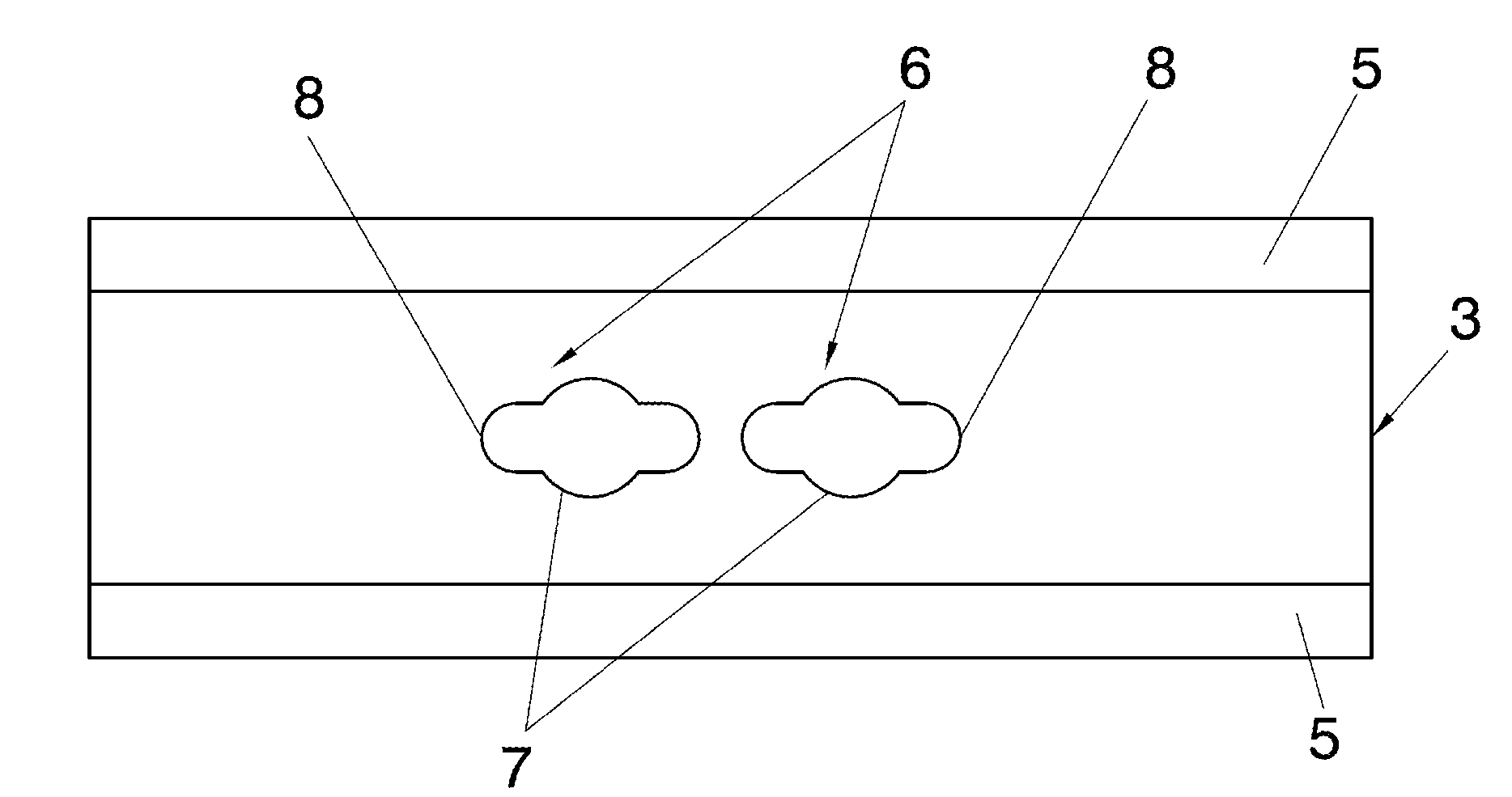

[0028] The part of the cutting blade 3 with double cutting edge 5 protruding from the periphery of such a support disc 1 is the part that performs the cutting of the sugarcane during the continuous rotation of the support disc 1 incorporated in the cutting device of the harvester.

[0029] The radial blades 3 incorporate pairs of through notches 6 through which fixing bolts 4 are introduced, by the heads of which fixing bolts 4 the radial blades 3 are fixed on the support disc 1 .

[0030] Each through-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com