Full-automatic groove broacher for wood processing

A fully automatic, wood technology, used in wood processing appliances, slotting machines, manufacturing tools, etc., can solve the problems of increasing processing steps, low work efficiency, prolonging processing time, etc., to avoid breakage, improve service life, and reduce load. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

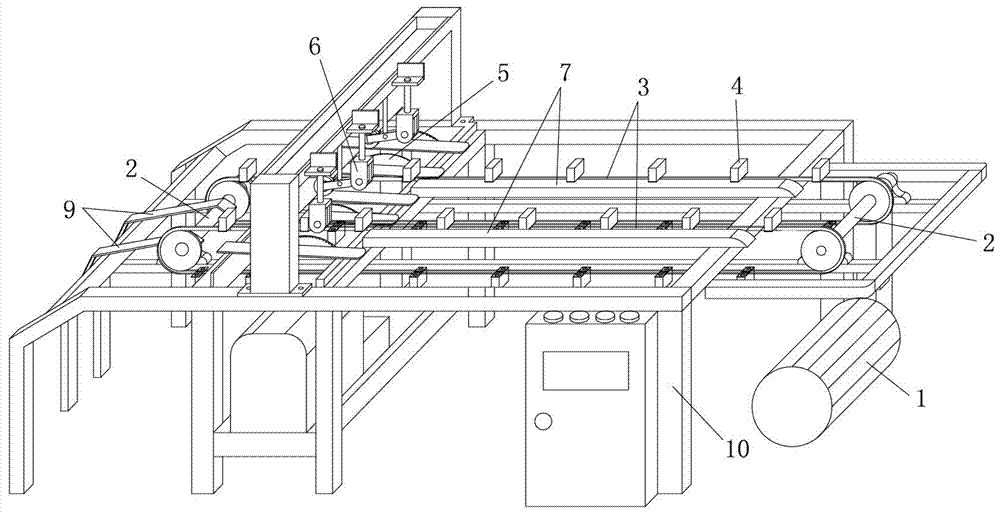

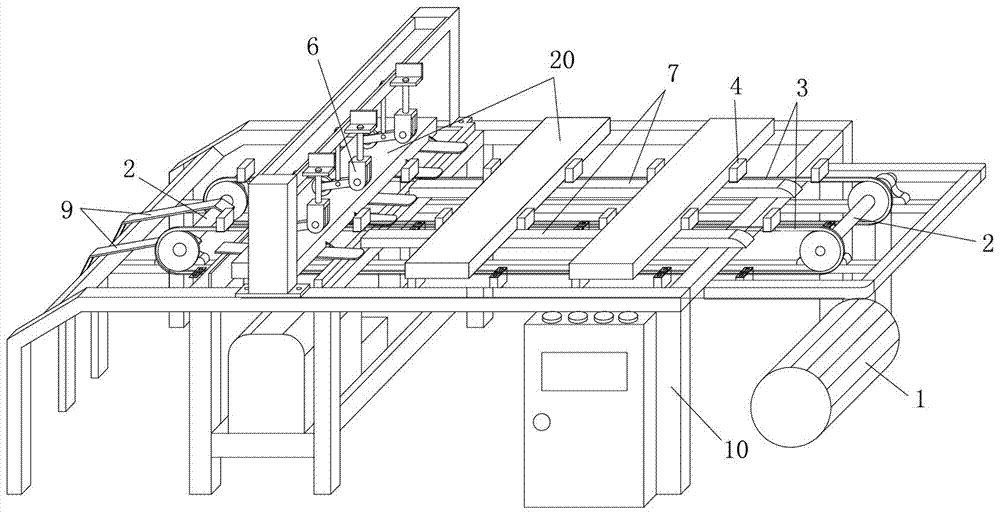

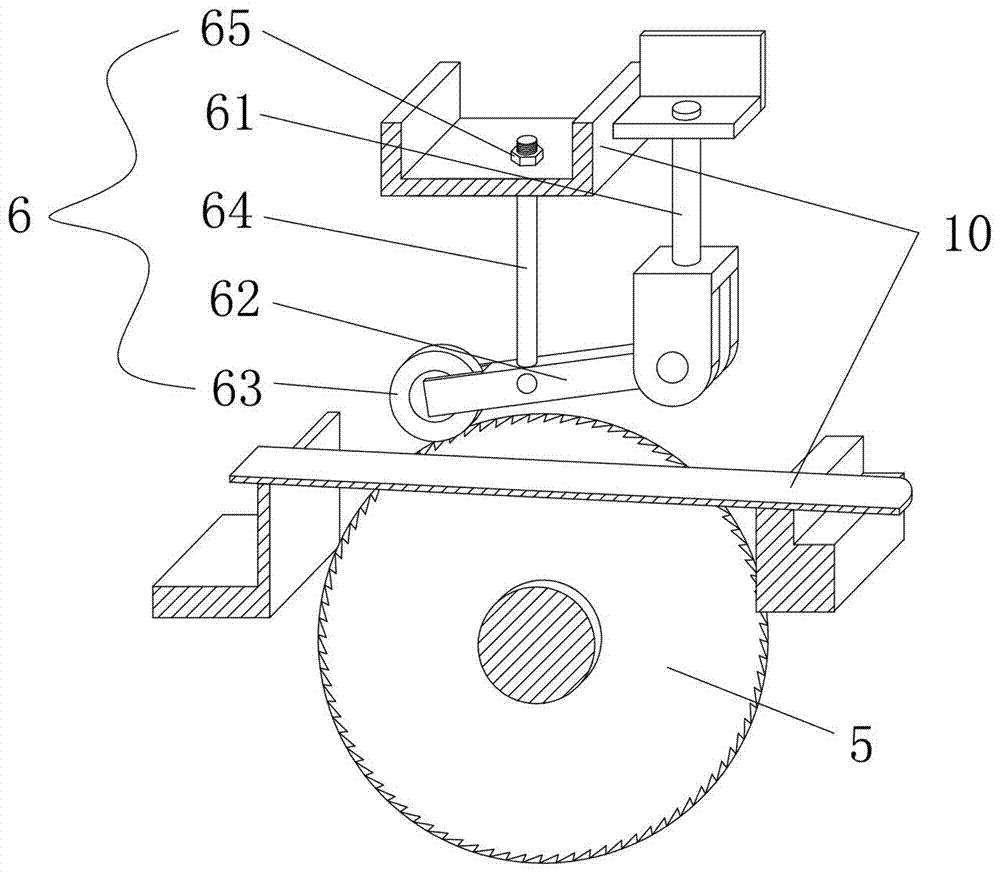

[0017] Such as Figure 1 to Figure 5 As shown, a fully automatic slotting machine for wood processing includes a frame 10, two parallel rotating shafts 2 are installed on the frame 10 and are driven by a driving mechanism 1, and at least two rotating shafts 2 are sleeved on the two rotating shafts. The transmission belt 3 of strip, every transmission belt 3 is evenly fixed with some transmission blocks 4, and timber 20 frame is placed on all transmission belts 3, every transmission belt 3 corresponding positions between two adjacent transmission blocks 4, frame 10 is set There is a groove cutter 5 located at the end of the running path of the wood 20, the cutter axis of the groove cutter 5 is horizontal and perpendicular to the running path of the wood 20, and the highest position of the groove cutter 5 is higher than the lower surface of the wood 20 on the transmission belt 3 and lower than the transmission belt 3. On the upper surface of the wood 20, the frame 10 is also pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com