Insert cutter

A cutting tool and plug-in technology, used in milling cutters, forming knives, manufacturing tools, etc., can solve the problems of insufficient cutting edge strength and lack of cutting edge, and achieve the effect of optimized force deflection and firm positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

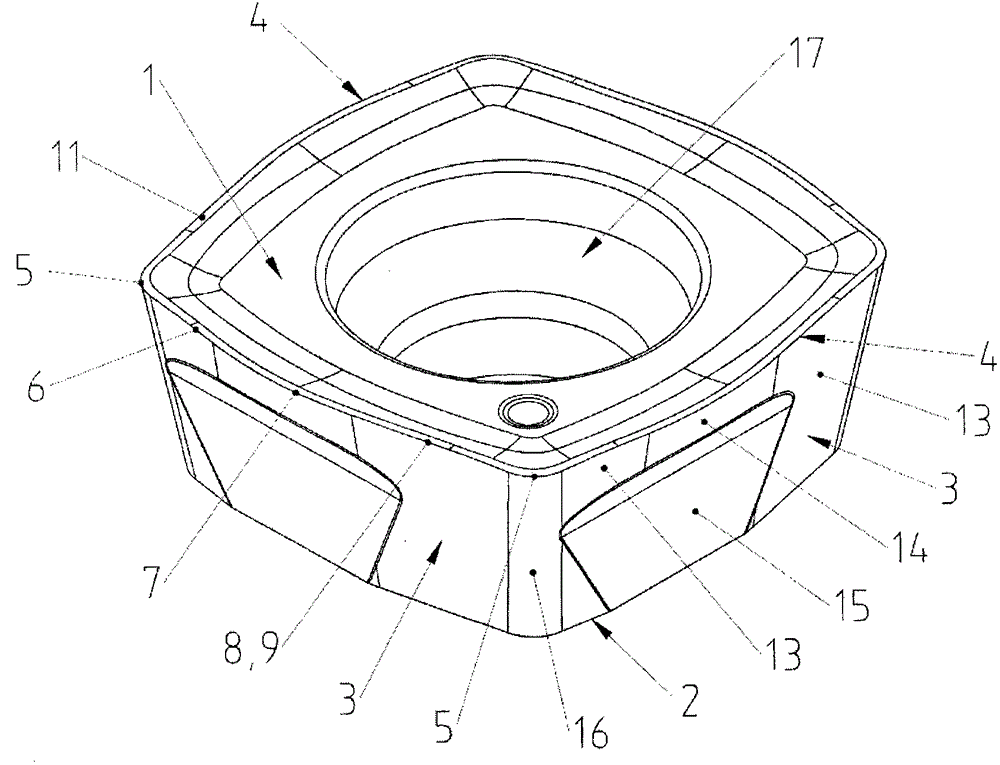

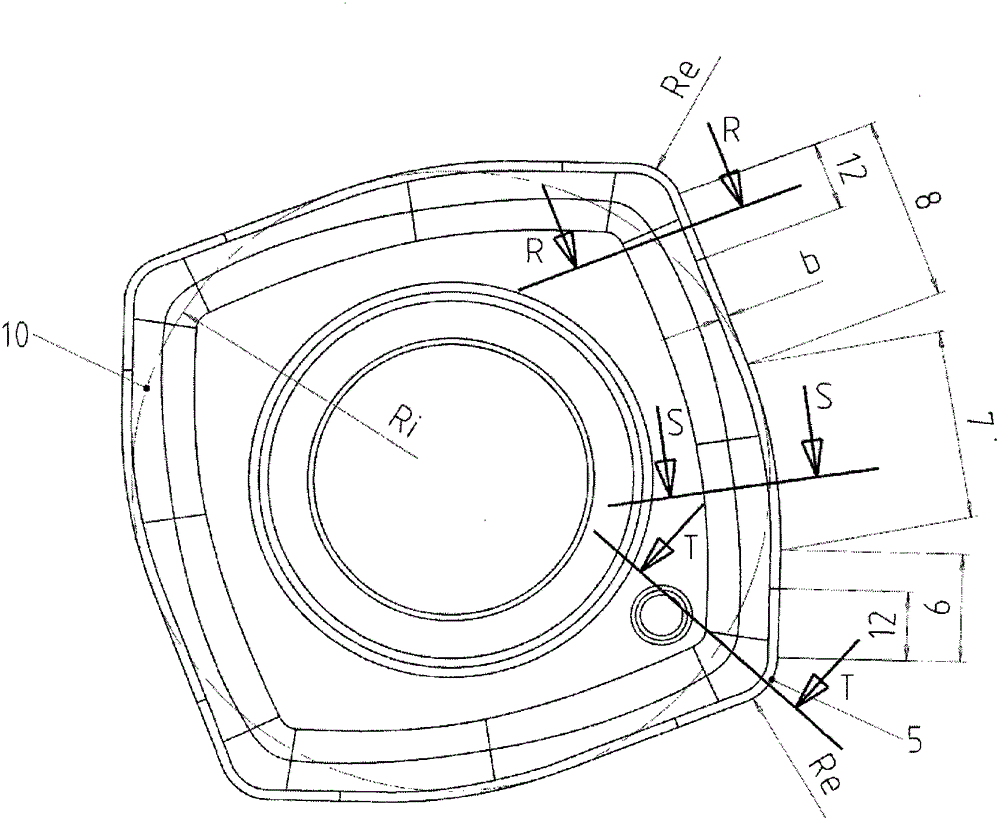

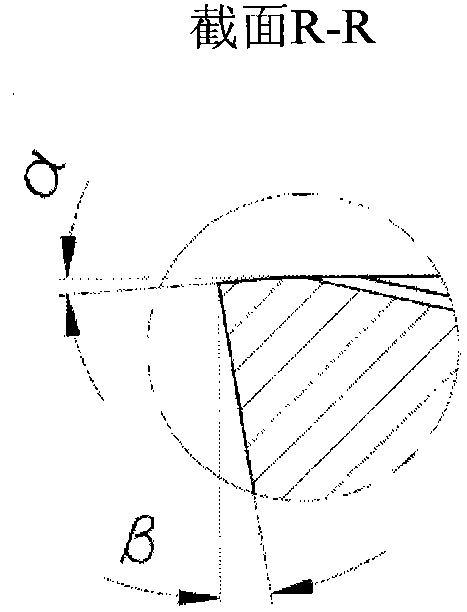

[0024] figure 1 and figure 2 , respectively a perspective view and a plan view, showing an insert cutting tool according to the invention having a square basic shape. The plunger cutting tool has a top face 1 , a bottom face 2 and a raised side face 3 inclined relative to the top face 1 at a clearance angle β. A raised cutting edge 4 is formed at the intersection between the top face 1 and the side face 3 . Each cutting edge 4 has a straight wiper edge 6 adjacent a cutting corner 5 . The wiper edge 6 then merges with the circular portion 7 into the main cutting edge 8 consisting of a straight portion 9 . The radius of the circular portion 7 is 70% of the radius Ri of the inscribed circle 10 . The theoretical circle that is inscribed in the top face 1 of the plunger cutter and touches all four cutting edges 4 is called the inscribed circle 10 . In the present case, the main cutting edge consists of a single straight portion 9 , but variants with up to three such straight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com