Steel hot bend orifice roundness calibration system and its method

A technology for calibrating systems and hot-simmering pipes, which is applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of low work efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

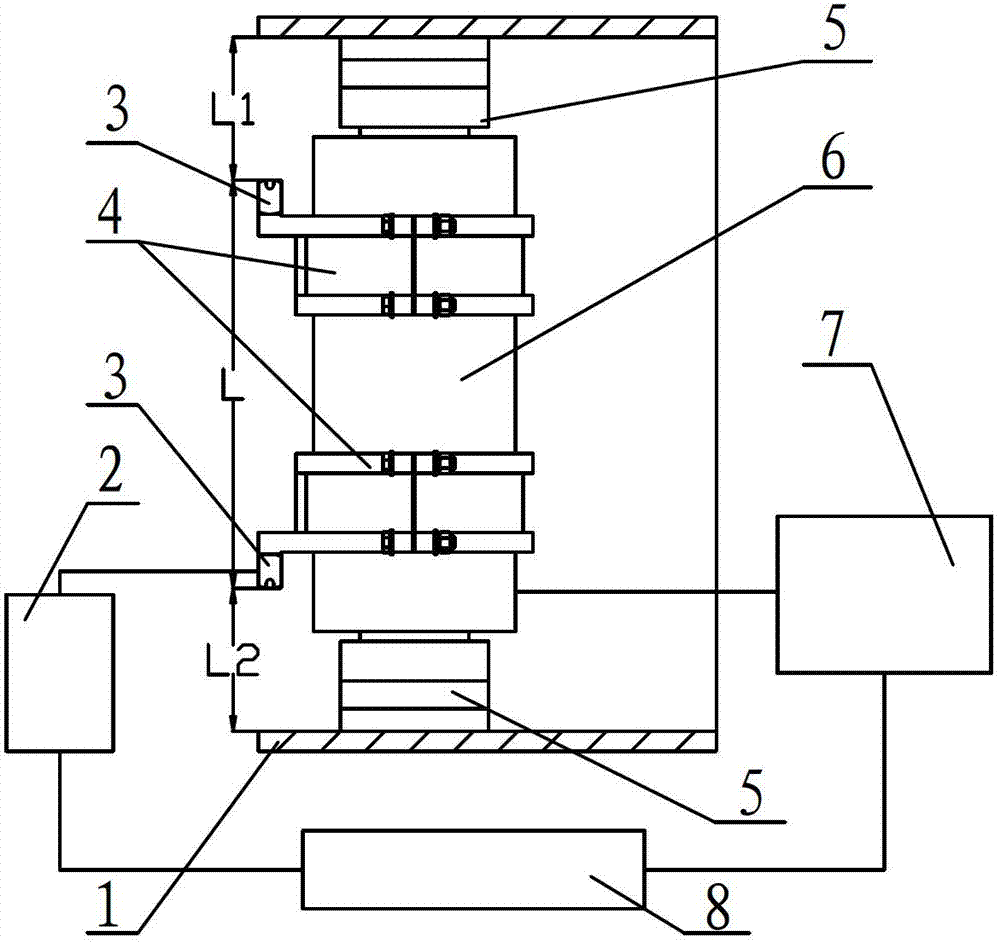

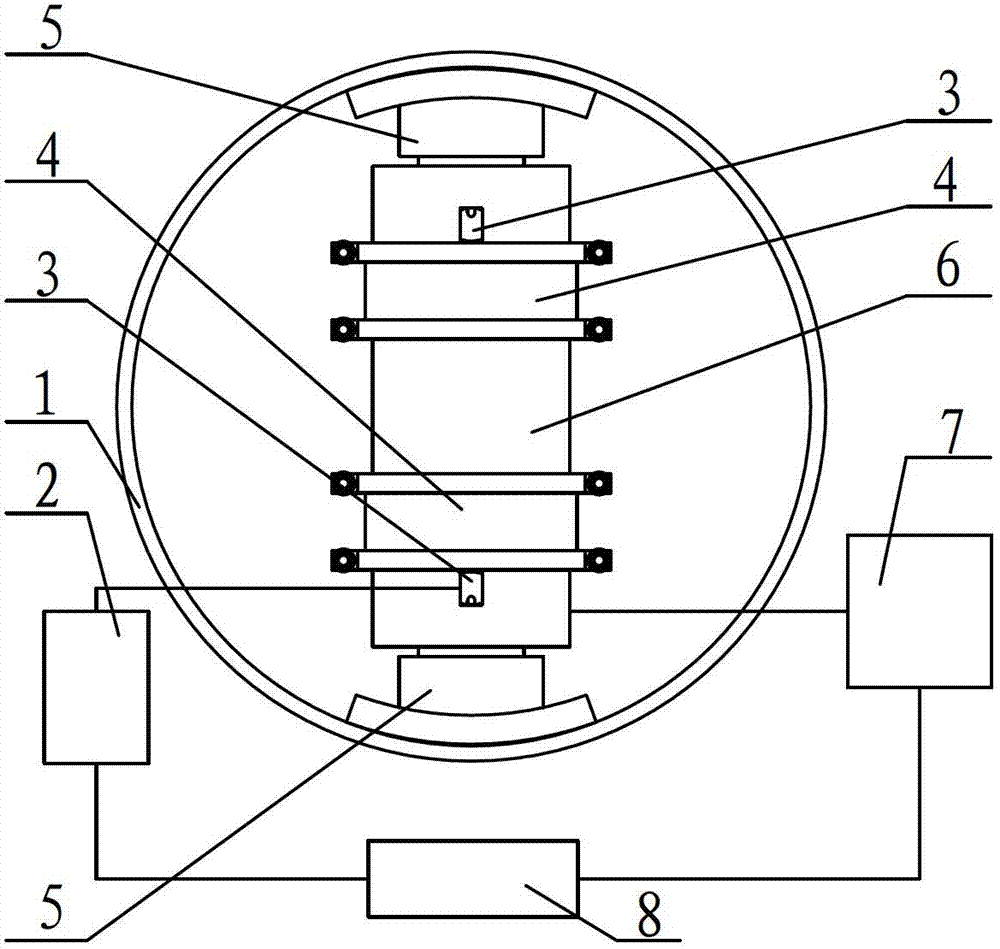

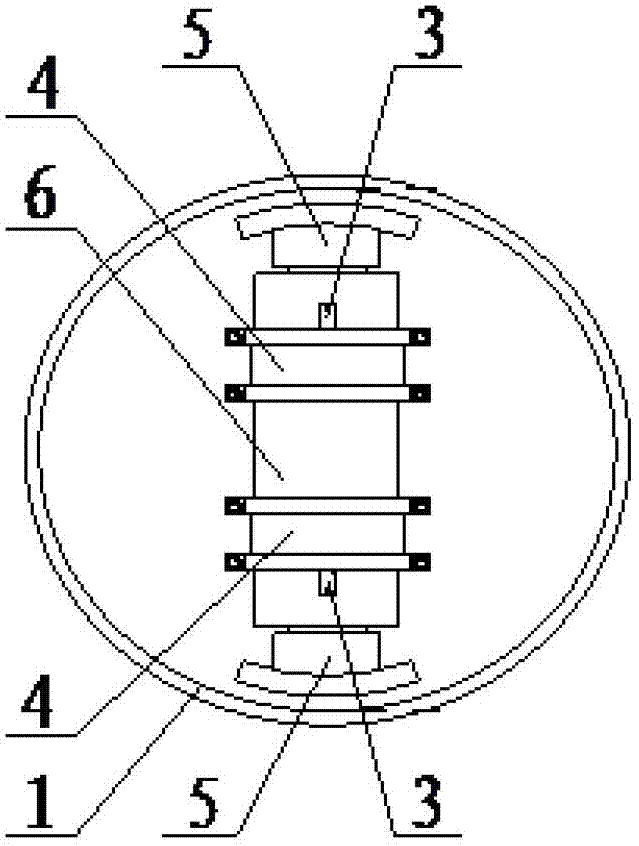

[0016] Such as Figure 1~2 As shown, a roundness calibration system of a steel hot-simmer-bent pipe nozzle provided in the embodiment of the present application includes a hydraulic cylinder 6 with a roundness calibration device (ie, a top cap 5) and a double piston rod, a hydraulic control system 8, A laser measurement and control system 10 for controlling the extension distance and retraction timing of the hydraulic cylinder 6 . Wherein, the laser measurement and control system 10 includes a laser sensor 3 and a laser measurement and control device 2 . The laser sensor is arranged on the hydraulic cylinder 6, and is used to measure the distance between the position of the laser sensor 3 and the pipe wall; The hydraulic control system 8 issues a control command; the hydraulic control system 8 controls the hydraulic cylinder 6 to calibrate the roundness of the nozzle according to the control command.

[0017] The number of laser sensors 3 is two, and the laser sensors 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com