Multi-stage racking machine

A fractionation and casing technology, which is applied in the field of multi-stage packing machines, can solve the problems of inconvenience in production and life, reduced scope of application, and the inability of large-volume materials to pass through, and achieve the effect of avoiding overweight weighing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

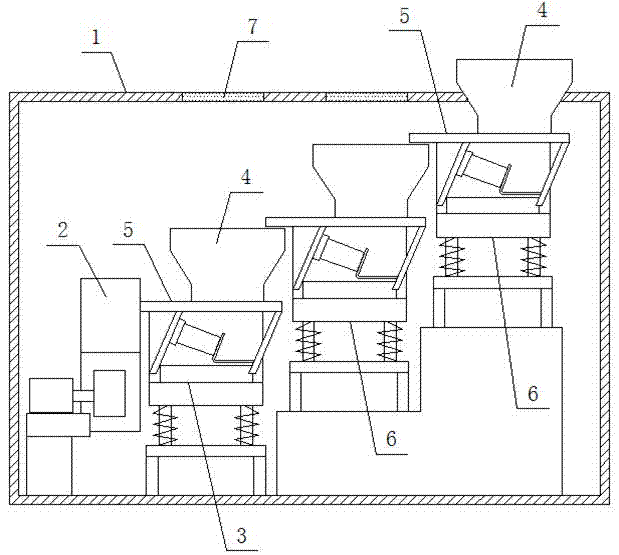

[0011] Example one: such as figure 1 As shown, a multi-stage packaging machine includes a casing 1, a weighing hopper 2 and a main vibrating hopper 3. The main vibrating hopper 3 is provided with a material hopper 4 and a feed channel 5, and the main vibrating hopper 3 The material channel 5 is located on the weighing hopper 2, and further includes at least one pair of vibrating bucket 6, so that the vibrating bucket has a 2-N level. In this embodiment, a three-level vibrating bucket is used, that is, two auxiliary vibrating buckets 6 are added. The structure of the auxiliary vibrating bucket 6 is different from that of the main vibrating bucket 3 according to different product requirements. It includes a material bucket 4 and a feeding channel 5, and the outlet of the feeding channel 5 of the first auxiliary vibrating bucket 6 is located in the main vibrating bucket 3. On the material hopper 4, the outlet of the feed channel 5 of the latter vibrating hopper 6 (that is, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com