Anti-prying packaging barrel

A packaging barrel and anti-pry technology, which is applied in the direction of locking equipment, etc., can solve the problems of poor anti-pry effect of packaging containers, no design of anti-pry and anti-theft on the container cover and main body, and achieve good anti-pry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

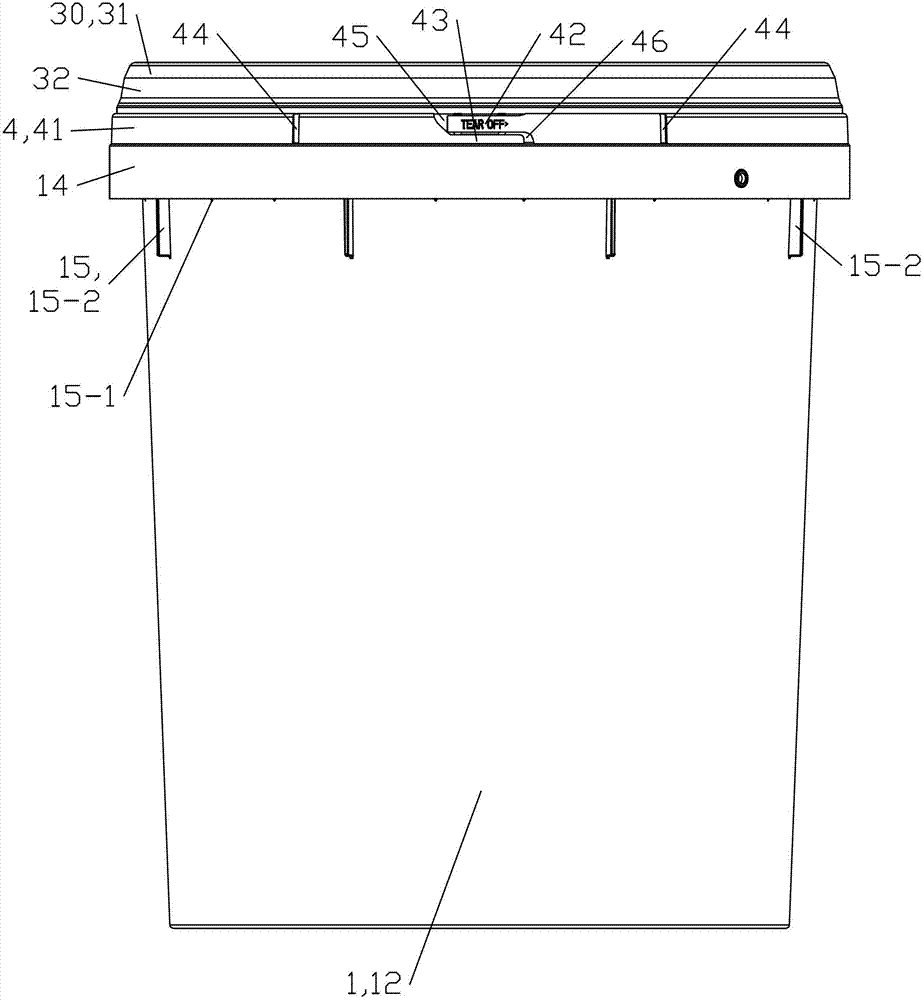

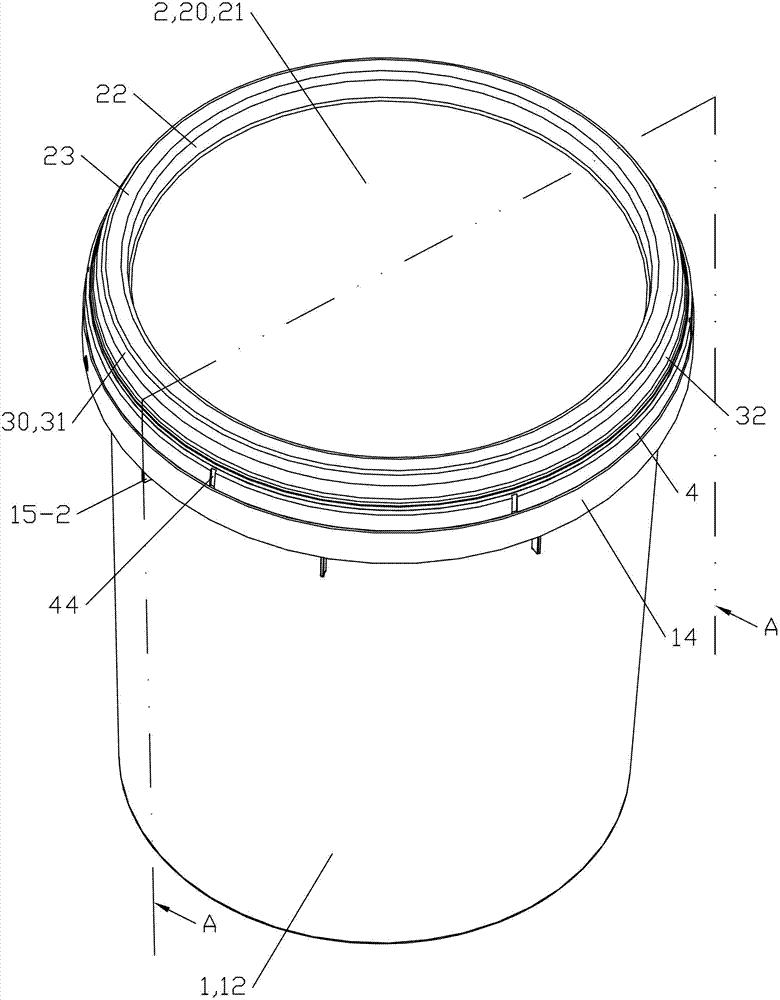

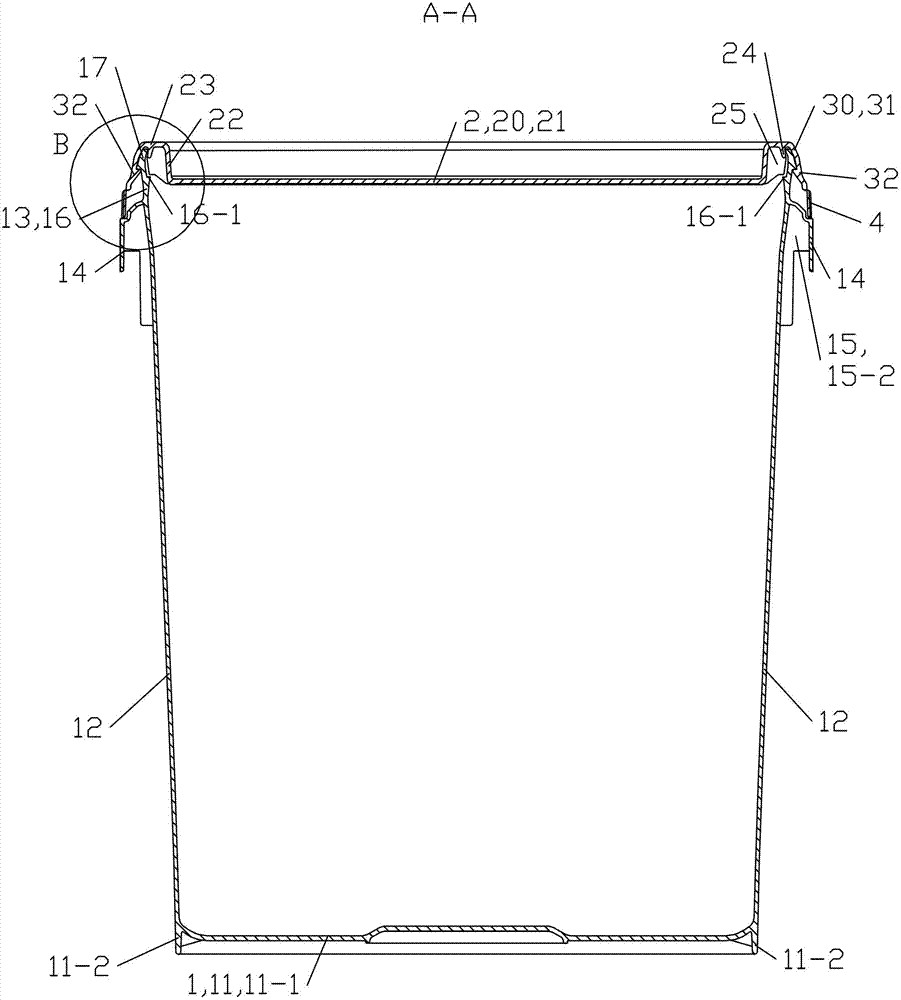

[0040] See Figure 1 to Figure 3 , The tamper-resistant packaging barrel of this embodiment is composed of a container body 1 and a cover body 2 . The cover body 2 is fixedly installed on the container main body 1 from above when in use. Both the container main body 1 and the cover body 2 are plastic integral parts made of polypropylene or high-density polyethylene pellets through injection molding. The container body 1 can be made into a barrel of any size according to the capacity requirement, and the capacity can be selected within the range of 0.5L to 60L. The cover body 2 is made into a corresponding shape and size according to the size of the container body 1 .

[0041] See Figure 1 to Figure 5 , The container body 1 is composed of a bottom 11 , an outer peripheral side 12 , a mouth 13 , a handle 14 and 24 reinforcing ribs 15 . The main body of the bottom 11 is a circular plate 11-1, and a circular vertical plate 11-2 located below is connected to the peripheral edg...

Embodiment 2)

[0056] The tamper-resistant packaging barrel of this embodiment is basically the same as that of Embodiment 1, the difference being that: see Figure 7 , the horizontal section of the groove 44 of the tear strip 4 is in the shape of an isosceles triangle, and its opening faces outward.

Embodiment 3)

[0058] The tamper-resistant packaging barrel of this embodiment is basically the same as that of Embodiment 1, the difference being that: see Figure 8 , the horizontal section of the groove 44 of the tear strip 4 is in the shape of an isosceles trapezoid, with its opening facing outward.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Circumferential length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com