Testing method for testing solid-solid contact thermal resistance by using forward and reverse bidirectional heat flux method

A technology of contact thermal resistance and test method, applied in the field of testing, can solve the problems of measurement accuracy of difficult interface contact thermal resistance, temperature measurement uncertainty error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

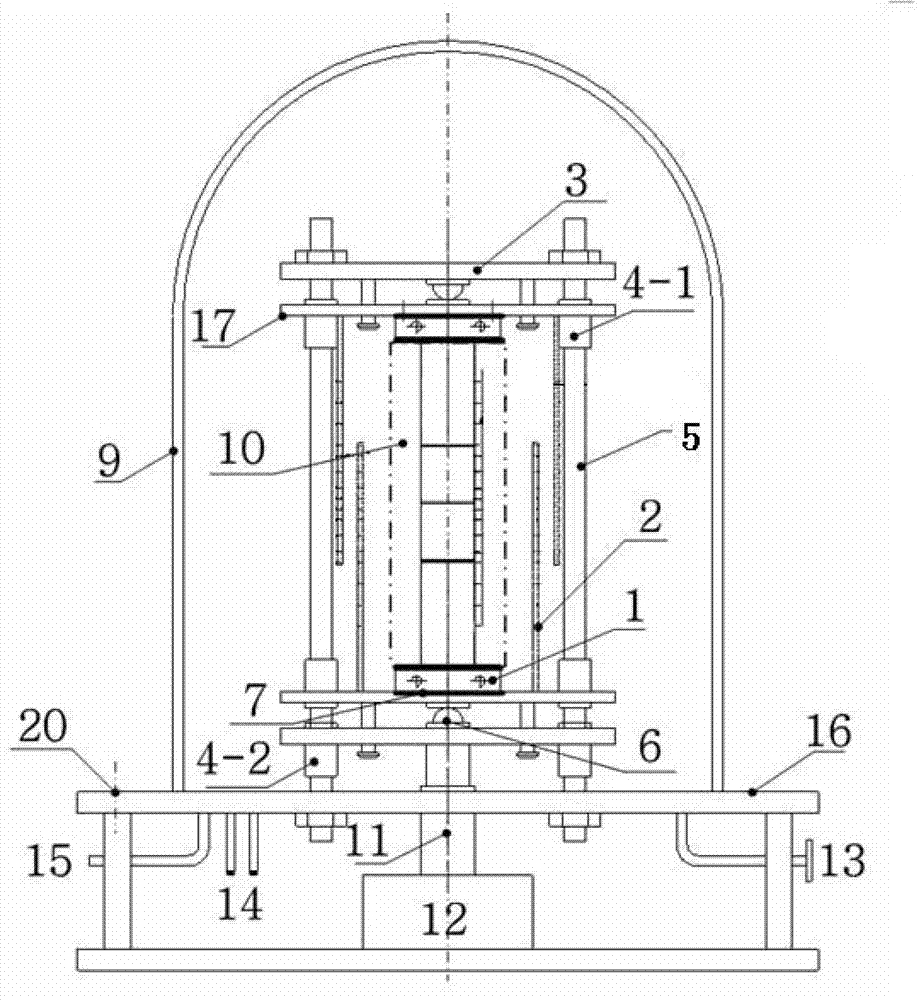

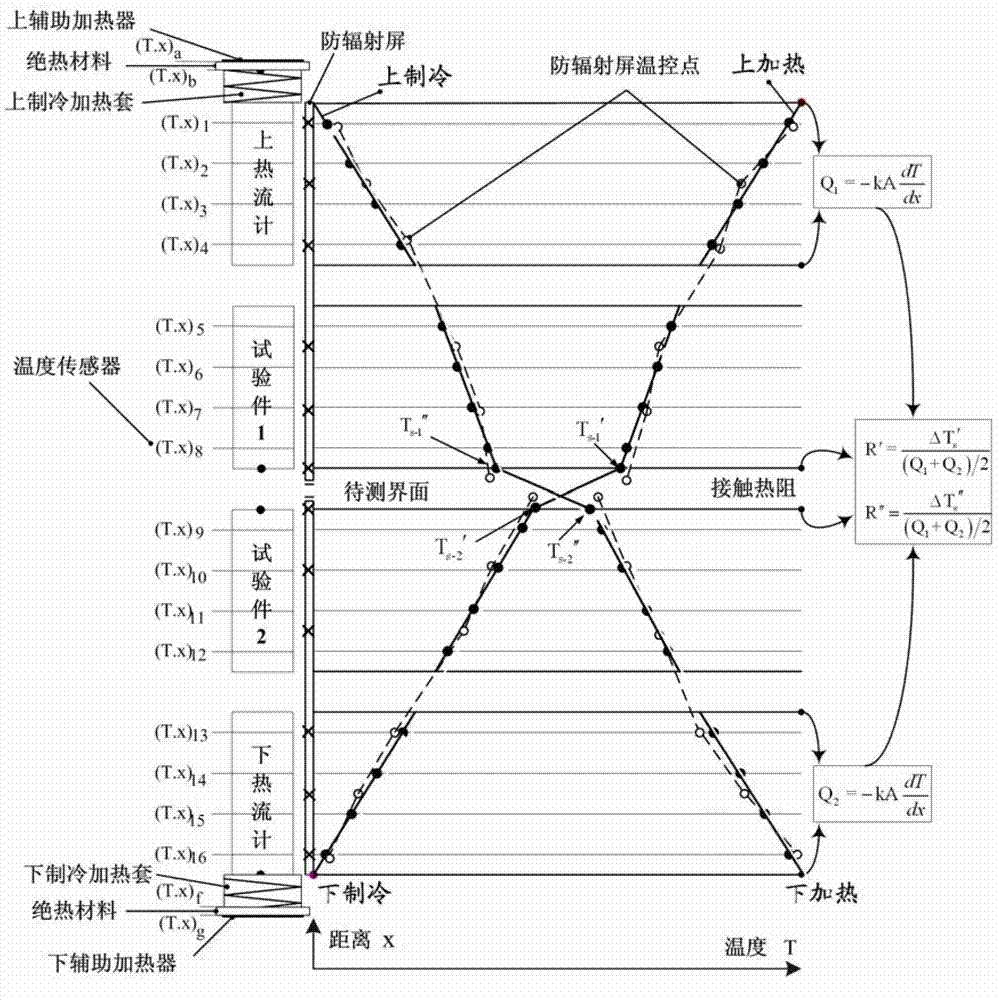

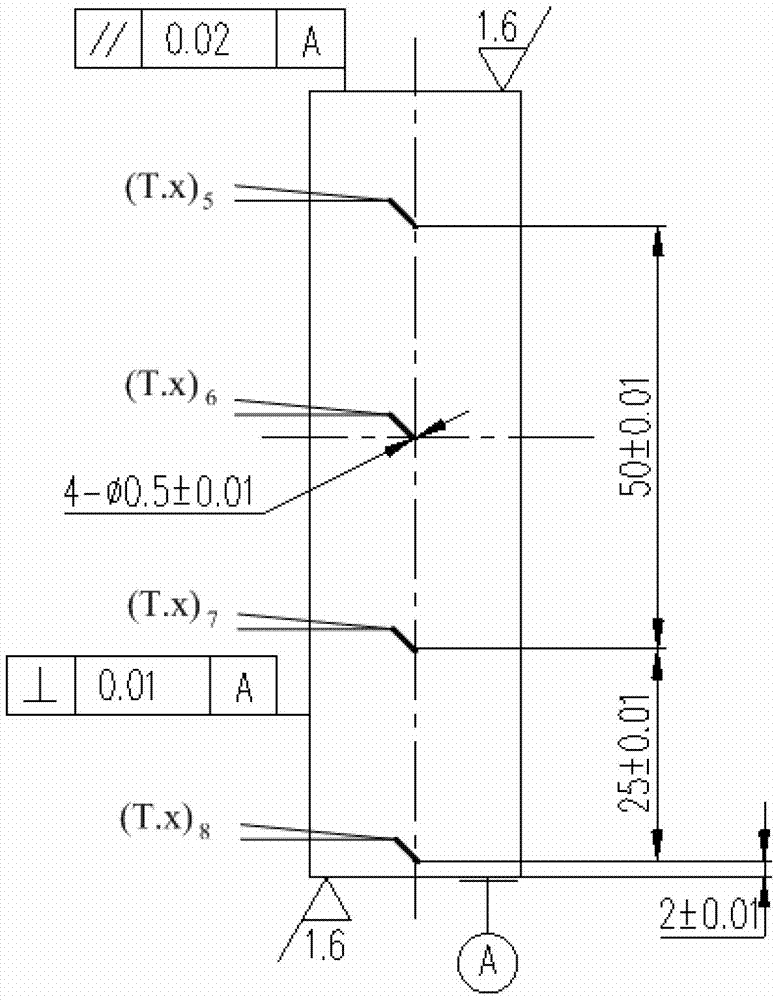

[0048] Therefore, in order to solve the above problems, the present invention proposes a method for measuring solid-solid contact thermal resistance by a positive and negative bidirectional heat flow method on the basis of American National Standards ASTM E1225 and ASTM D5470. The symmetrical structure test structure can basically eliminate the uncertainty error of temperature measurement due to the different contact conditions between the multiple temperature sensors arranged on the test piece and the test piece, thereby improving the test accuracy. Combining the temperature-controllable thermal radiation shield and auxiliary measures to reduce the loss of lateral heat flow, and adopting an optimized minimum test heat flow to ensure the one-dimensionality of the temperature gradient of the test material to achieve high-precision test thermal properties of the specimen For the purpose of parameters, this method can measure the interface thermal resistance between the same mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com