Special fixture for producing top fly barrel

A special fixture and placket technology, applied in the direction of sewing tools, etc., can solve the problems of reducing product weight and production efficiency, inconvenient control of the width of the door lining, and unstable overlapping of door strips, etc., to achieve compact structure and avoid staggering , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

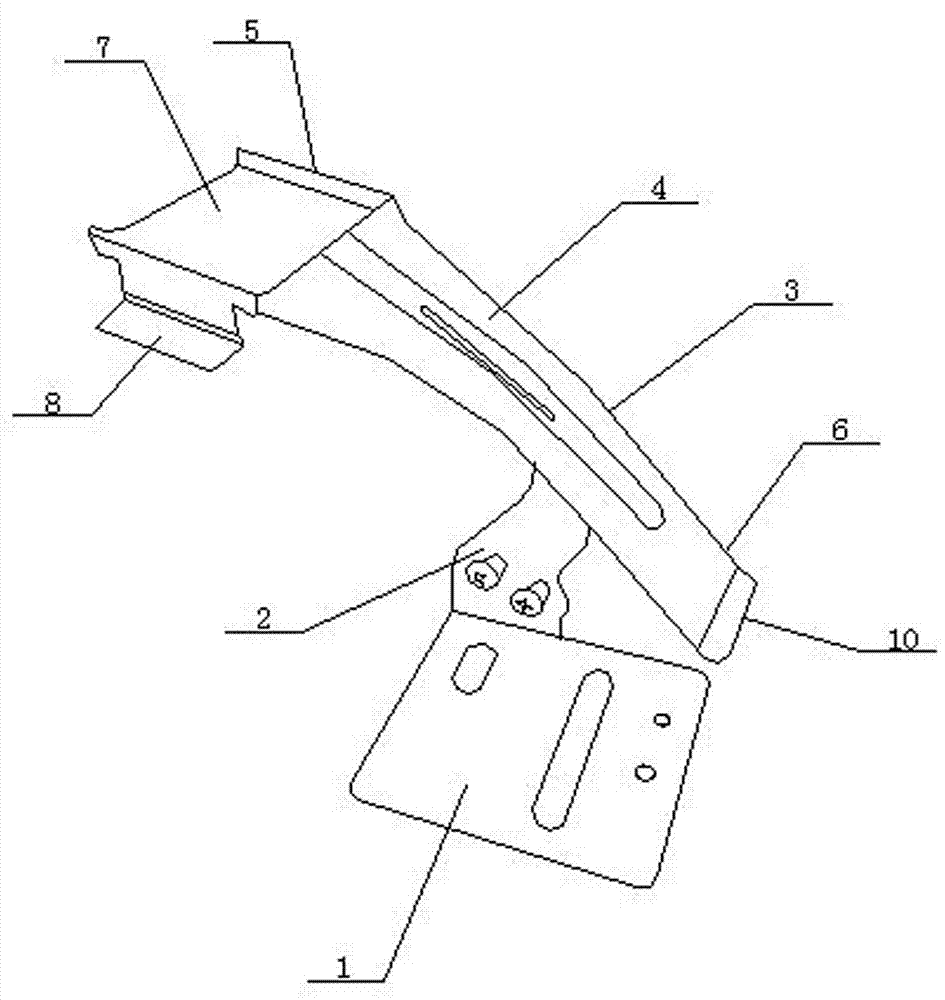

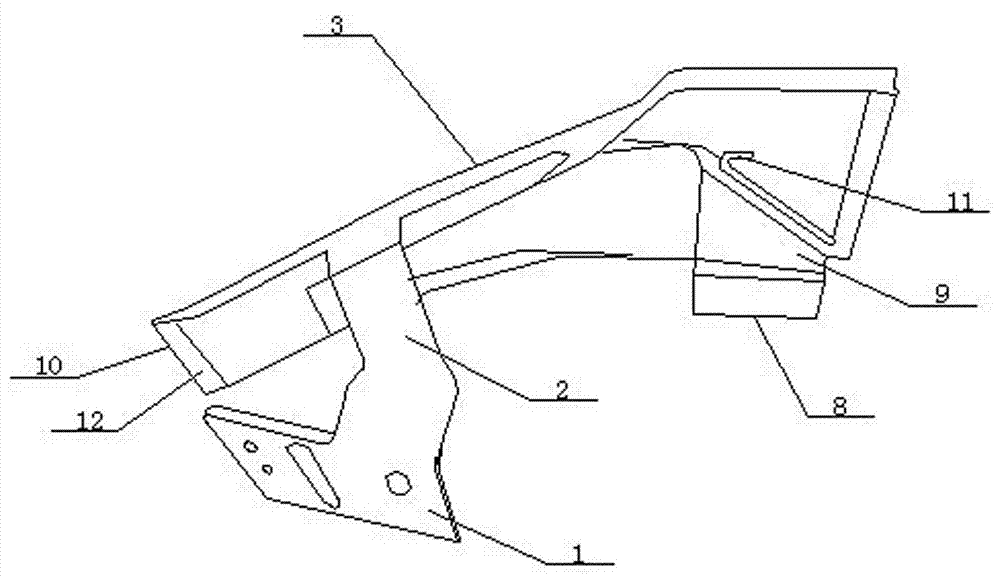

[0010] refer to figure 1 , figure 2 , the specific embodiment adopts the following technical scheme: a special fixture for producing the placket cylinder, which includes a support 1, a bracket 2, and a cylinder body 3, the support 1 is connected to the bracket 2, and the bracket 2 supports the cylinder body 3. The cylinder body 3 includes an arc-shaped cylinder body 4, an upper end portion 5, and a lower end portion 6. The upper end portion 5 is provided with a door strip inlet portion 7 and a door liner inlet portion 8. The door strip inlet portion 7 is above the door liner inlet 8; the barrel body 4 is provided with a door strip channel and a door liner channel parallel to each other, the door bar channel is connected with the door liner inlet 7, and the door liner inlet 8 is connected to the door liner channel by a trapezoidal transition plate 9; the lower end 6 is provided with an outlet 10.

[0011] refer to figure 2 , The transition plate 9 is provided with a hook 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com