Baboon drum-centering mechanism for bamboo breaking machine

A technology of centering mechanism and bamboo tube, which is applied to wood processing appliances, wood splitting devices, manufacturing tools, etc., can solve the problems of increased cutting amount, unequal bamboo wire width, affecting the life of slicing equipment, etc., and achieve centering accuracy. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

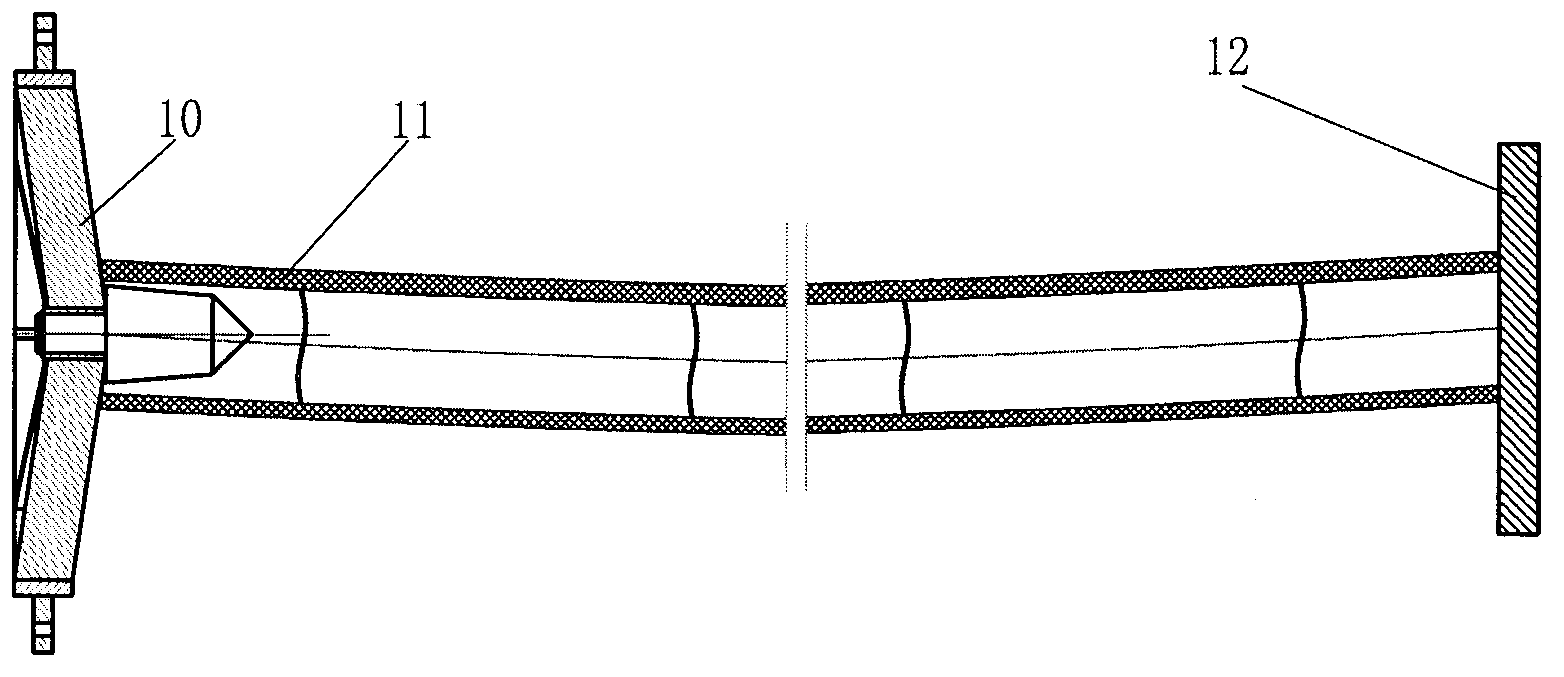

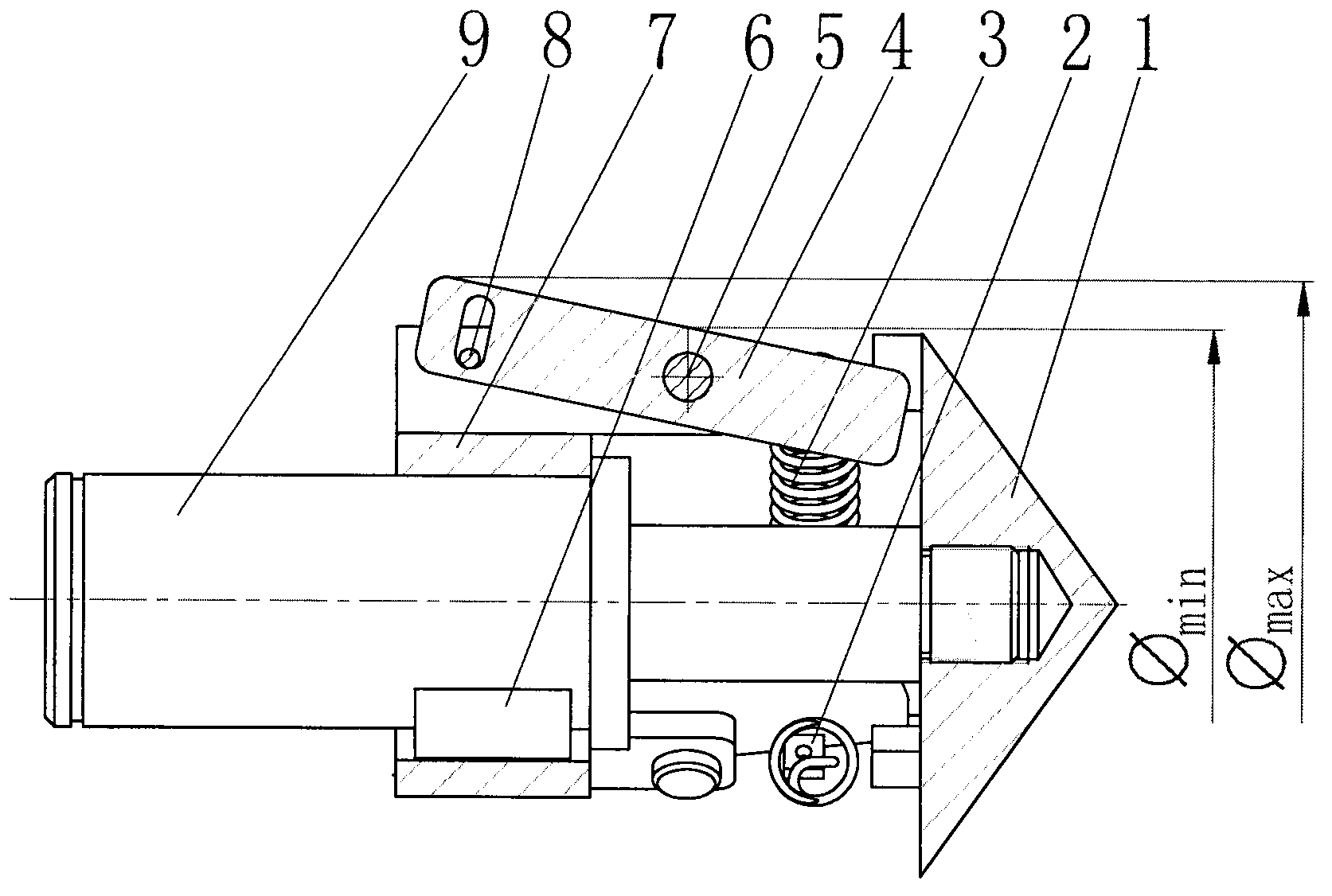

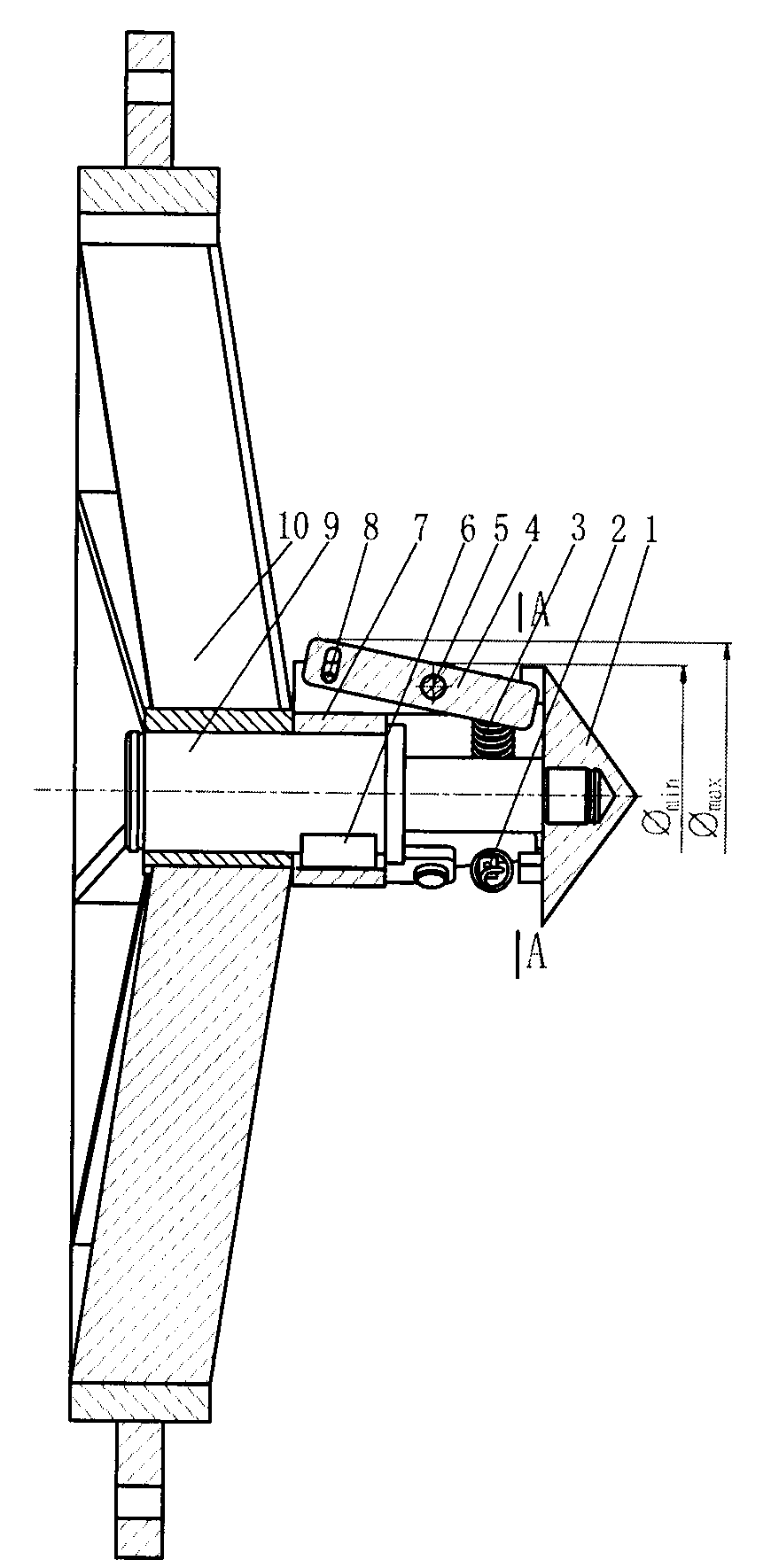

[0020] Bamboo centering mechanism (such as figure 2 As shown), the front cone 1 and the mandrel 9 are threadedly connected, the strut support 7 is set in the middle of the mandrel 9, and the flat key 6 is used to realize the circumferential fixing of the strut support 7 and the mandrel 9, and the pin 5 Hinge the three struts 4 respectively in the three grooves of the strut support 7, the two ends of the front ends of the three struts 4 are equipped with extension spring seats 2, and hook the two ends of the three extension springs 3 on the extension spring seats 2 respectively (Such as Figure 7 As shown), the three struts 4 form a cone with a small front and a large rear, and are concentric with the front cone 1 and the mandrel 9; the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com