Measurement-while-drilling mud pulser and method for controlling same

A mud pulse and measurement-while-drilling technology, which is applied in the directions of measurement, earthwork drilling, borehole/well components, etc., and can solve the problems of normal operation and reliability of interference brushes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The use of directional terms such as "top", "bottom", "up", "down", "vertical" and "horizontal" in the following descriptions is for relative reference purposes only and is not intended to imply any Any restrictions on placement of or how any equipment may be installed into the module or with respect to the environment.

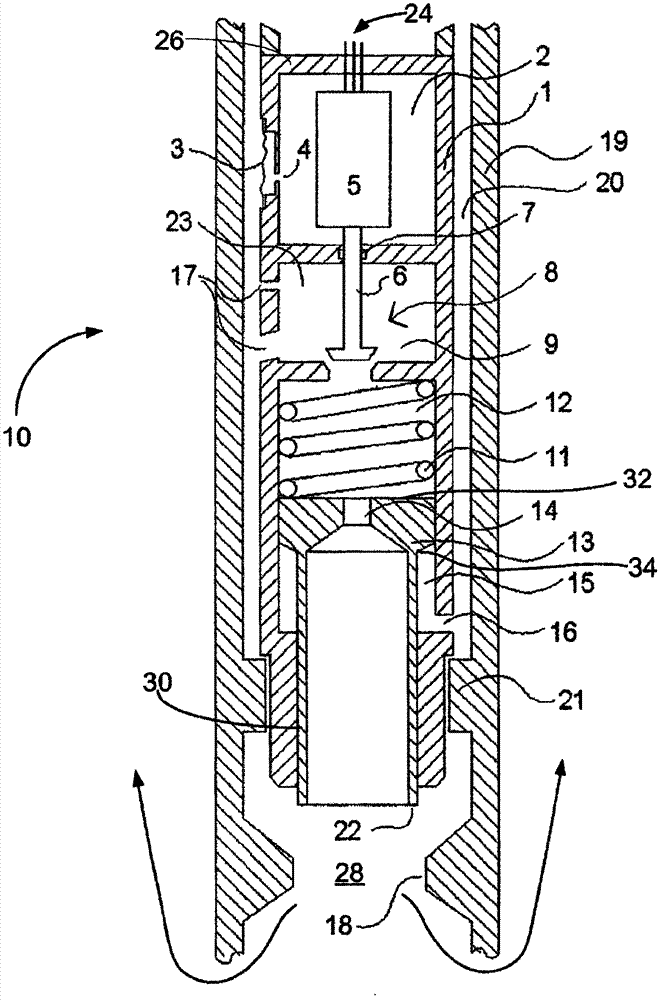

[0057] figure 1 A drill pipe bottom hole assembly (hereinafter simply referred to as "drill pipe") 19 is shown in which an exemplary mud pulser 10 is disposed. The mud pulser 10 comprises a main housing 1 retrievably located on fins 21 provided in a drill pipe 19 . The connection to the drill pipe 19 may also include a mule shoe arrangement to ensure rotational alignment of the orientation sensor housed in the mud pulser 10 . The main casing 1 is smaller in diameter than the drill pipe 19 to form an annulus 20 through which drilling mud can flow. An orifice collar 18 is provided in the drill pipe 19 below the fins 21 for forming an orifice or restri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com