LED down light taking base bracket as mounting interface

A technology of LED downlights and base brackets, which is applied to components of lighting devices, cooling/heating devices of lighting devices, lighting devices, etc., and can solve problems such as difficult maintenance, restrictions on the popularization and use of LED lighting, and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

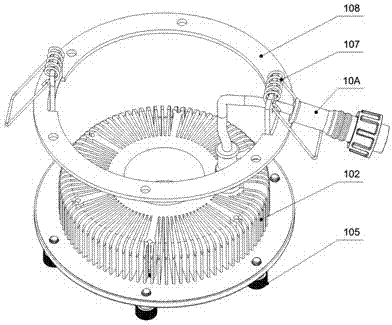

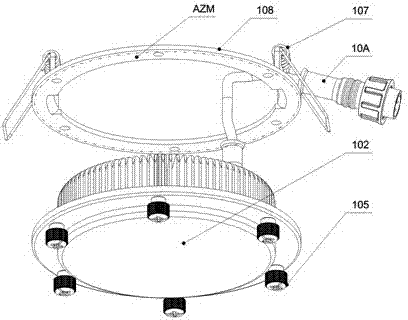

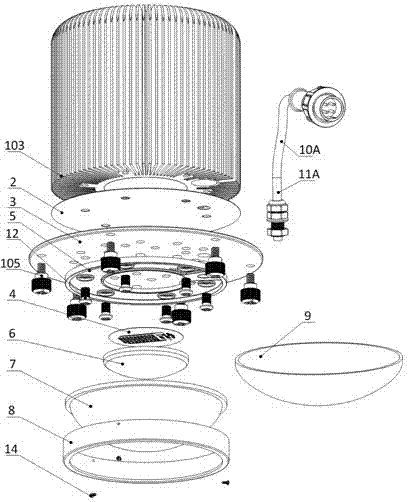

[0083] LED downlights with the base bracket as the installation interface, such as figure 1 , figure 2 with Figure 24 As shown, it includes a downlight lamp, and the downlight lamp includes a base bracket 108 and a spring fixing card 107. The base bracket 108 is in a ring shape, and the spring fixing cards 107 are arranged on both sides of the base bracket 108; The installation interface AZM is set on the 108 to fixedly install the LED bulb 102 . The installation interface AZM includes the contact surface of the base bracket 108 and the LED bulb 102 and the connection hole. The installation interface AZM on the base bracket 108 includes radiator interface openings and 6 flange fixing holes, the flange fixing holes are used to fix the LED bulb 102, and the radiator interface openings are used to make the LED bulb 102 penetrate the installation interface; the flange The fixing holes are evenly distributed on the diameter D1, and the diameter D1 is the outer diameter D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com