Belt-driven elevator without counterweight

A technology without counterweights and elevators, which is applied in elevators, transportation and packaging in buildings, etc. It can solve the problems of complex devices, guide elements wear, traction power, increase, etc., and achieve the effect of limited cost and high friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

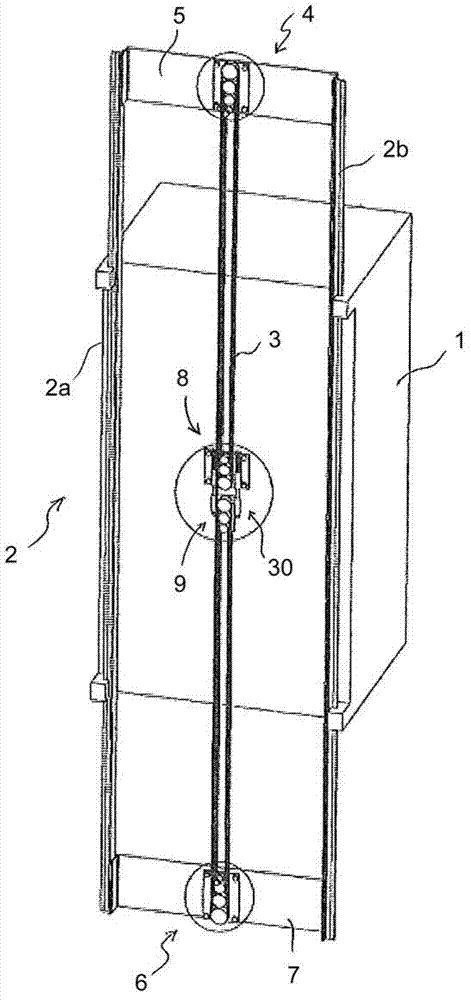

[0034] Figures 1 to 5 It relates to an embodiment of the invention wherein the elevator without counterweight comprises a car 1 and a frame structure 2 with guide rails 2a, 2b for said car 1 . When the drive system is in operation, the car 1 moves in the vertical direction relative to the frame structure 2 . In this embodiment, the drive system comprises a single drive belt 3 arranged behind the car 1 .

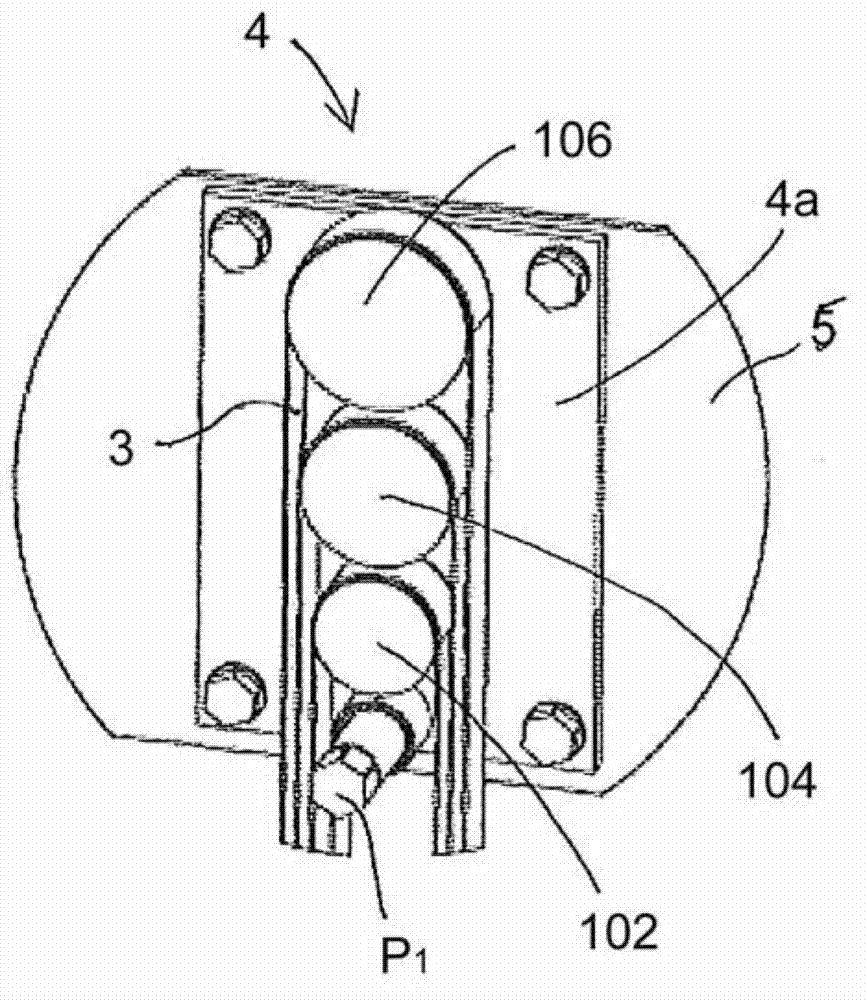

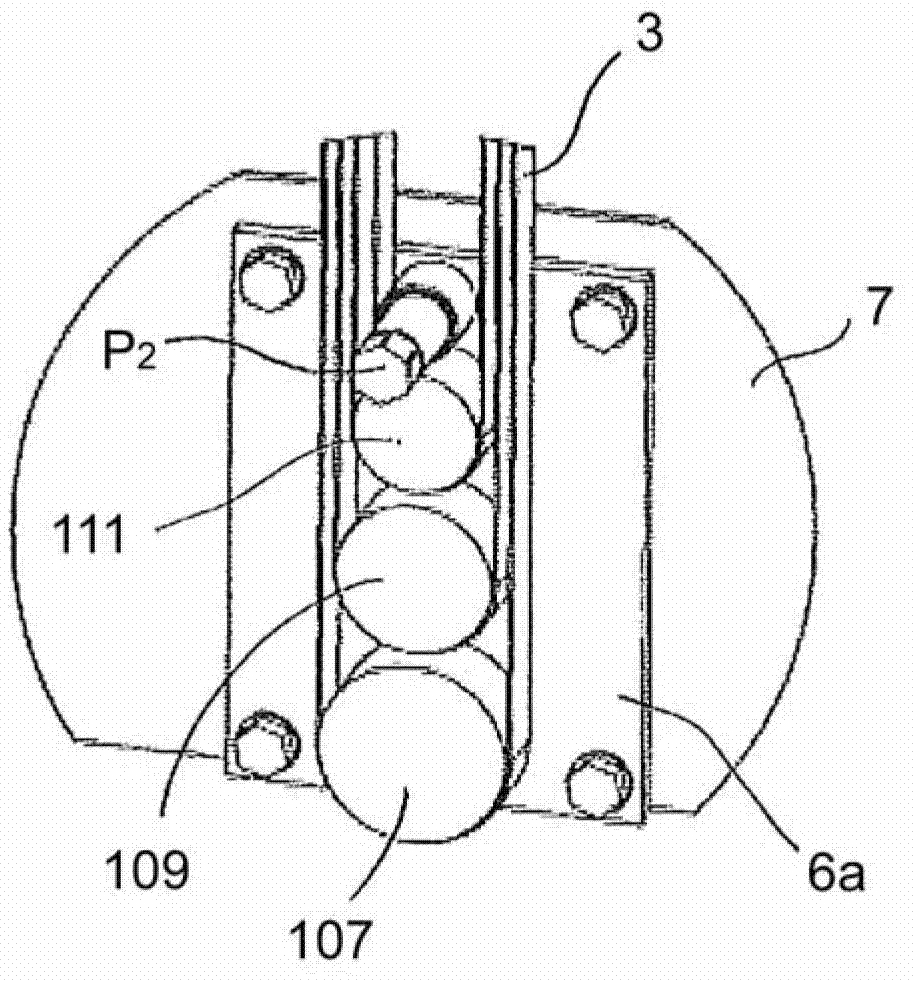

[0035] The drive system comprises a plurality of stationary pulleys arranged in sets 4 fixed to the top element 5 of the frame structure, and sets 6 fixed to the bottom element 7 of the frame structure. The drive system also comprises movable pulleys arranged in sets 8 , 9 connected with the car 1 .

[0036] The pulley and belt arrangement can be easily changed from Figure 5 recognized in. from around the first anchor bolt P 1 The fixed terminals of the belt 3 respectively go around the pulleys 101 to 112 and reach the anchor bolts P 2 relative to the fixed terminal. ...

no. 2 example

[0048] Figures 6 to 8 Embodiments with multiple drive belts are involved. and Figures 1 to 5 Those corresponding parts are indicated by the same numerals.

[0049] In this example the elevator has two drive belts 3a and 3b. Embodiments with more than two belts are also possible.

[0050] The compensating means 30 are common between the two belts 3a and 3b, as Figure 6 shown. The belts 3a and 3b are wound around movable pulley blocks 8, 9 connected to the car 1 ( Figure 6 ), thus having a common compensating device 30 .

[0051] A first pulley set 8 is rotatably supported on a plate 20, fixed to the rear of the car 1, and a second pulley set 9 is rotatably supported on a plate 21, suspended to the plate 20 by means of pins 22, 23 and associated springs 26, 27 . Figure 6 express with Figure 4 The spring arrangement differs from the spring arrangement in which the spring abuts against a bushing fixed to the floating plate. Figure 4 or 6 spring arrangements are su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap