Pipe branch section for downpipe

A technology for downpipes and branch fittings, applied in the field of branch fittings, which can solve problems such as large installation space, sewage discharge capacity of branch fittings, or negative volume flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

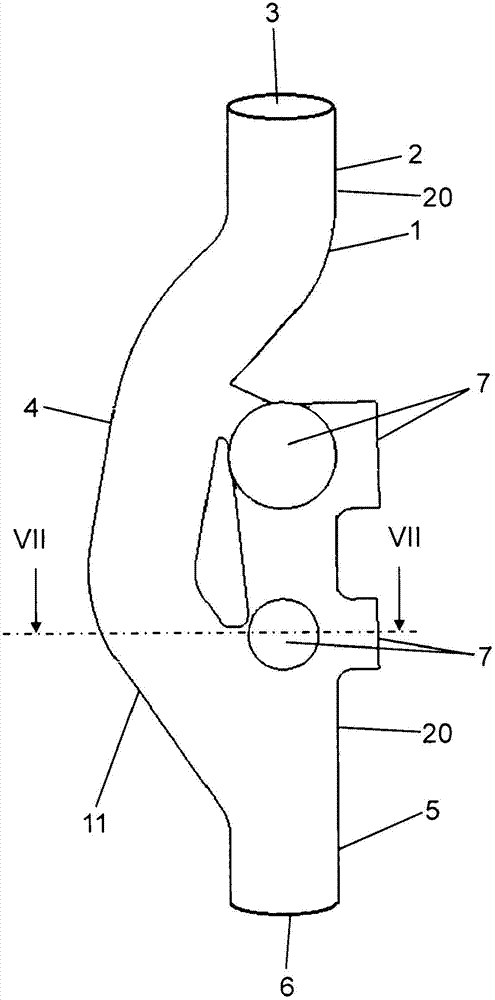

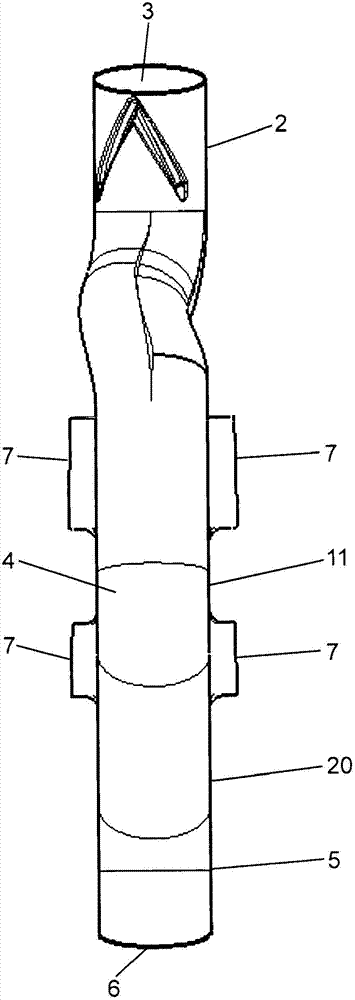

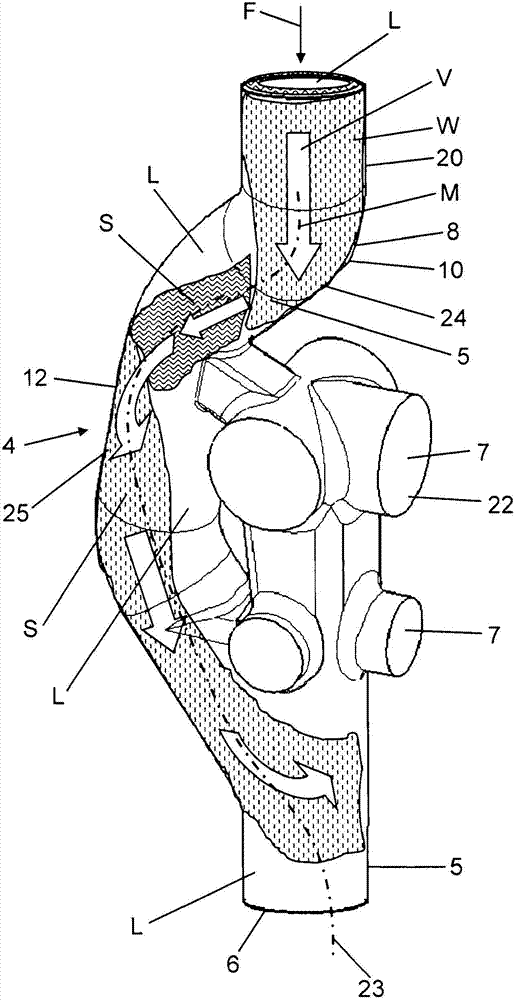

[0028] figure 1 and figure 2 A branch fitting 1 for application in a sewage downpipe of a multi-storey building is shown. Branch fittings 1 are used to connect the sewage supply pipes from a floor into a downpipe which extends from floor to floor, usually over the entire height of the building. The supply pipe is thus connected to the downpipe via the branch piece 1 .

[0029] The branch piece 1 comprises: an upper downpipe part 2 with an inflow opening 3; a deflection part 4 adjoining the upper downpipe part 2; a lower downpipe part 5 adjoining the deflection part 4 and having an outflow opening 6; and at least one feed pipe section 7 through which additional sewage is introduced into the downpipe. The upper downpipe part 2 , the deflection part 4 and the lower downpipe part 5 are surrounded by a wall 11 , 20 . The upper downpipe part 2 of the branch piece 1 is connected to an upper downpipe (not shown) and the lower downpipe part 5 is connected to a lower downpipe (also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com