Top straight water flushing squatting pan

A technology for squatting toilets and water flushing, applied in flushing toilets, water supply devices, buildings, etc., can solve the problems of water resource loss, easy aging of sealing rubber, high cost, etc., and achieve improved flushing of squatting pans, easy installation and maintenance, and easy replacement The effect of accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

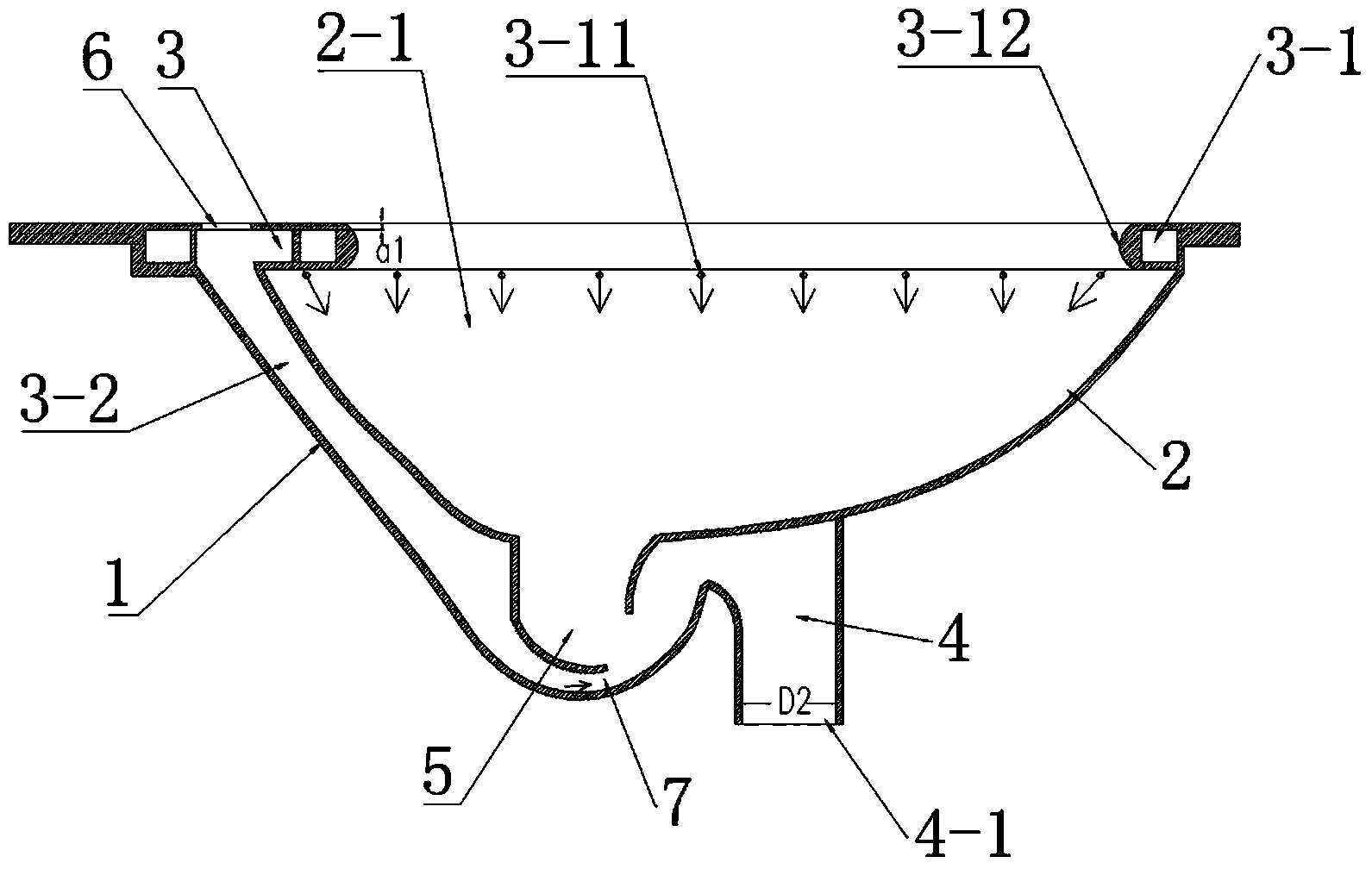

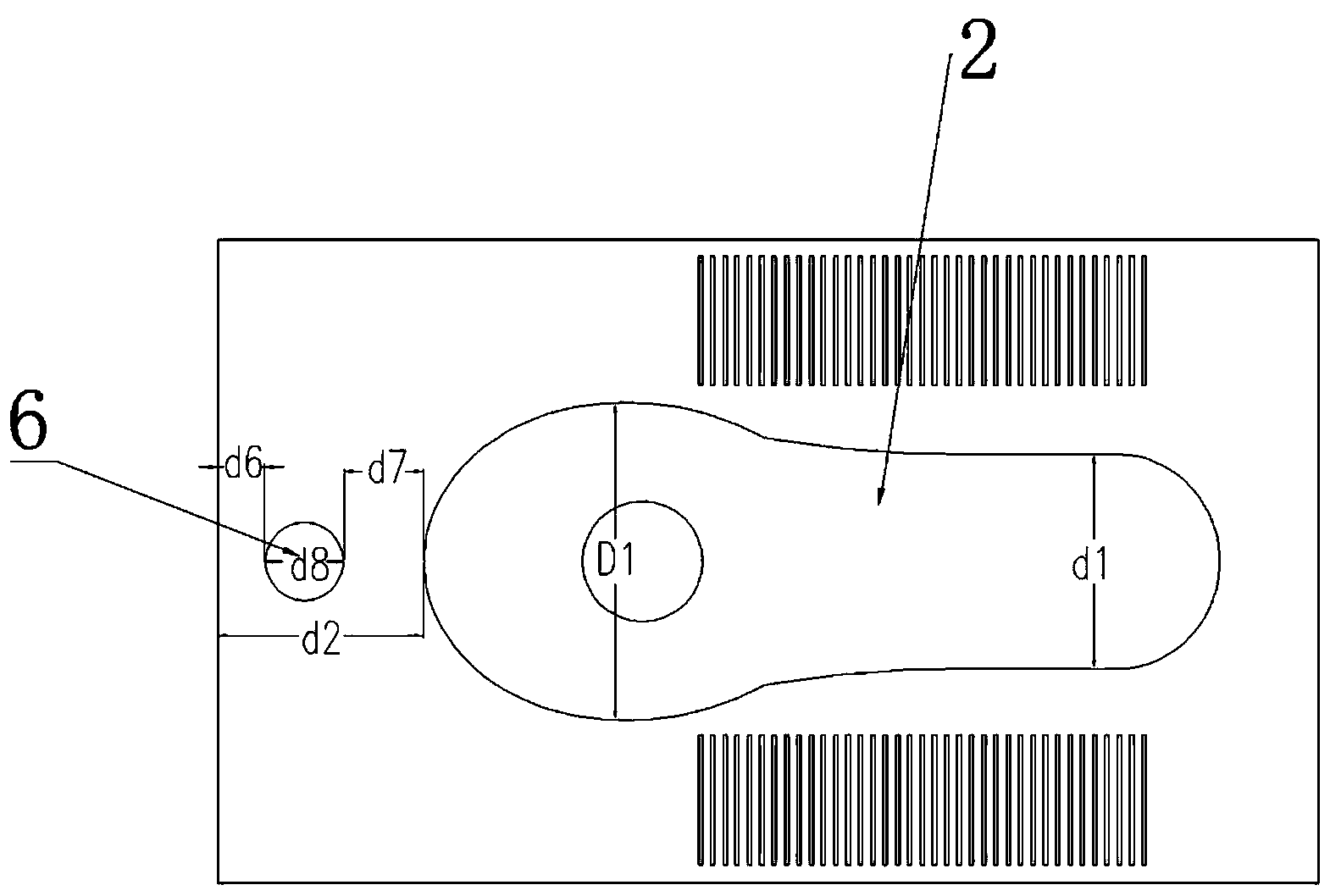

[0036] Such as figure 1 and figure 2As shown, a squatting pan with straight top water inlet of the present invention comprises a squatting pan main body 1, a squatting pan 2 arranged on the squatting pan main body 1, a flushing channel 3 and a sewage channel 4, and a water seal 5 is provided at the bottom of the squatting pan 2 , the water seal 5 communicates with the sewage channel 3, and the top of the squatting pan main body 1 is provided with a jacking water hole 6, and the jacking water hole 6 communicates with the flushing channel 4, and the water inlet pipe is externally connected. The squatting pan main body 1 is ceramic or metal or plastic product. The flushing channel 3 includes a flushing channel 3-1 around the city and an auxiliary flushing channel 3-2. The flushing channel 3-1 around the city is arranged around the upper edge of the squatting pan and is equipped with a plurality of flushing holes 3-11, wherein A plurality of flushing holes 3-11 are distributed ...

Embodiment 2

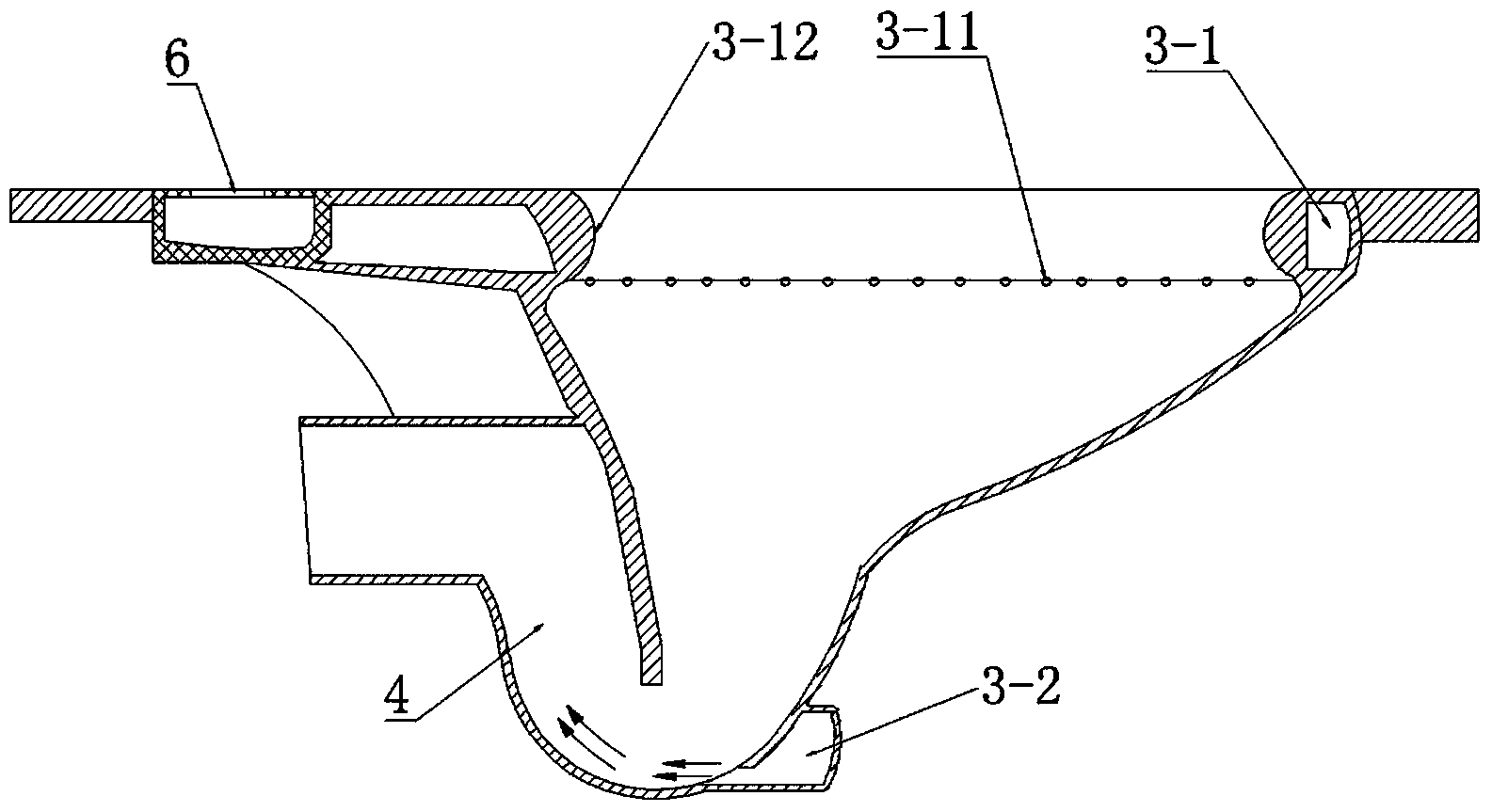

[0039] Such as image 3 As shown, the difference between this embodiment and the above-mentioned embodiment is that the entrance of the sewage channel is arranged at the rear of the water seal 5, and the number of auxiliary punching holes 7 is one, which is arranged at the front of the water seal 5. The water channel 3-2 extends from the rear of the squatting pan 2 to the front of the squatting pan 2 and is connected with the auxiliary punching hole 7.

Embodiment 3

[0041] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the number of the auxiliary punching holes 7 is two, which are respectively arranged on the side and bottom of the water seal, and the water flow direction of the two auxiliary punching holes 7 flows to the sewage channel Entrance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com