Coil grouping method for stator module combined motor

A coil grouping and combination technology, which is applied in the direction of prefabricated windings embedded in motors, manufacturing of motor generators, electrical components, etc., can solve the problems of difficult maintenance, difficult disassembly and maintenance of motors, large vibration and noise, etc., and achieve the effect of mechanical decoupling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

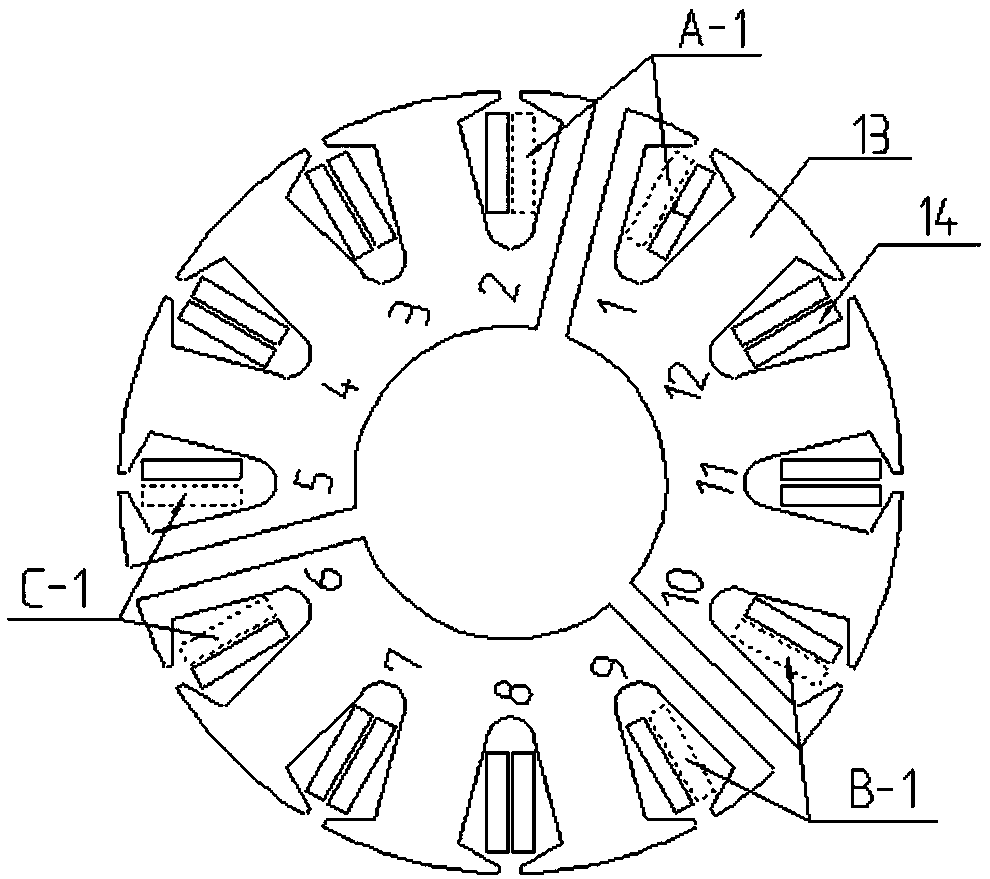

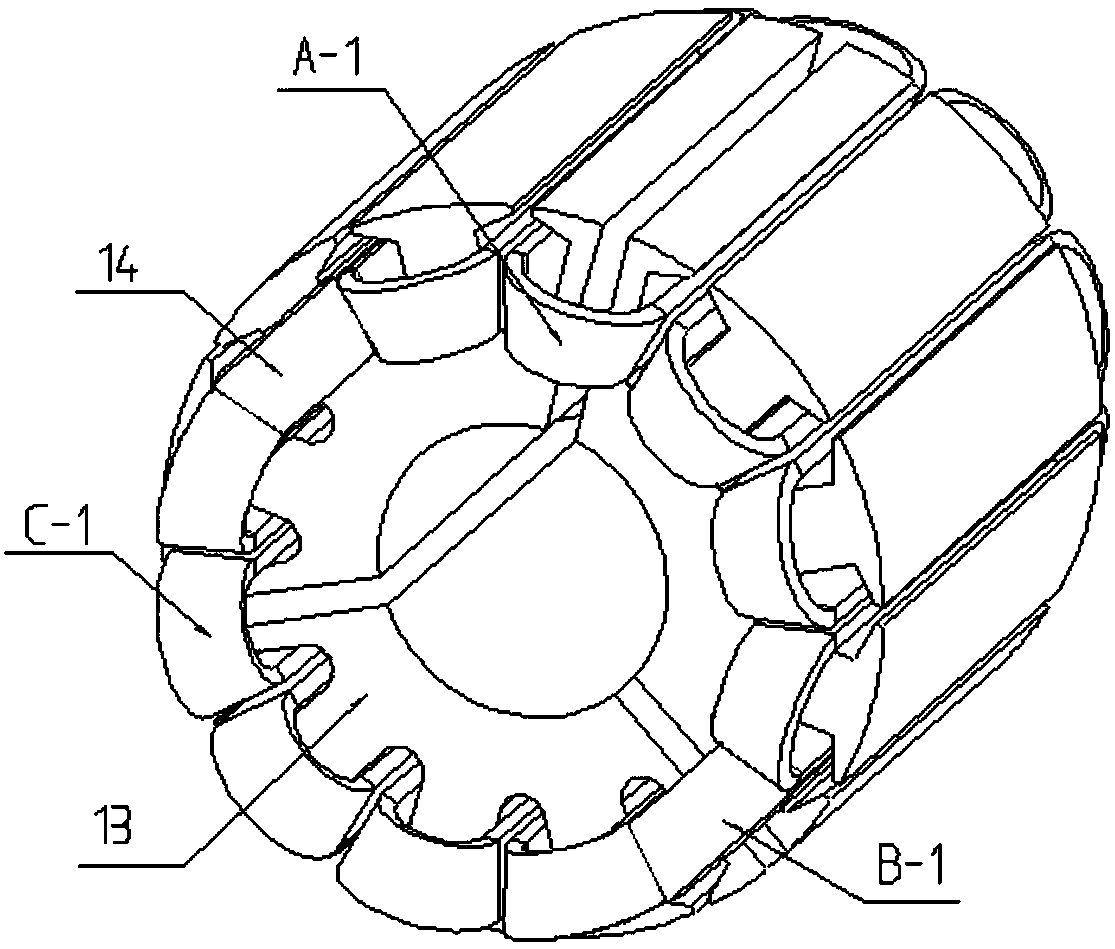

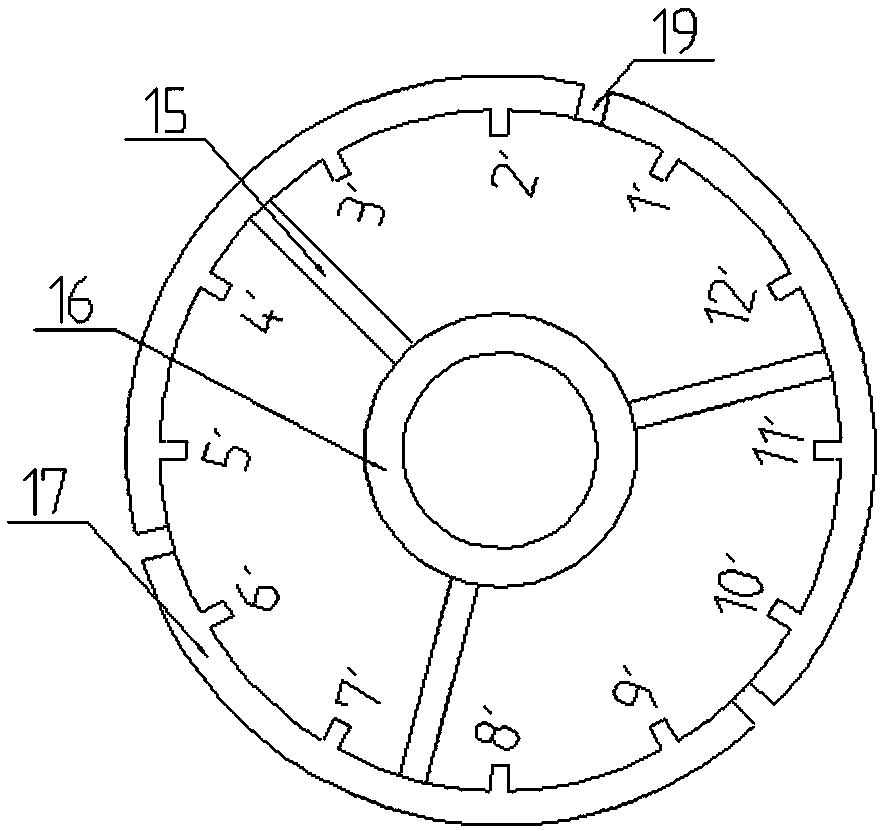

[0019] Such as figure 1 with figure 2 As shown, this embodiment takes a unit motor with 10 poles and 12 slots as an example for illustration. The stator core 13 is laminated by punched sheets, and the end is pressed by a stator pressure ring. Twelve stator slots are evenly opened on the outer circumference of the stator core 13, and the coil 14 is inserted into the stator slot according to the rule of straddling one stator tooth. The number of motor stator slots is Q 1 , the number of module slots according to a single stator block is Q 0 = Q 1 The rule of / s is divided into equal blocks, Q 0 must also satisfy Q 0 =12*(n / 6+k), where n =1, 2, 4 or 5, k=0, 1, 2 or 3.......Natural number, the number of stator blocks is s, s is The law of 3 or integer multiples of 3. This embodiment Q 1 =12, s=3, Q 0 =12 / 3=4, 4=12*(2 / 6+0), n=2, k=0, conforming to n =1, 2, 4 or 5, k=0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com