Steam Turbine Rotor Stress Online Real-time Monitoring System

A real-time monitoring system, a technology for steam turbine rotors, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as maintenance difficulties, dependence on hardware platforms, etc., to achieve the effect of convenient use and universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

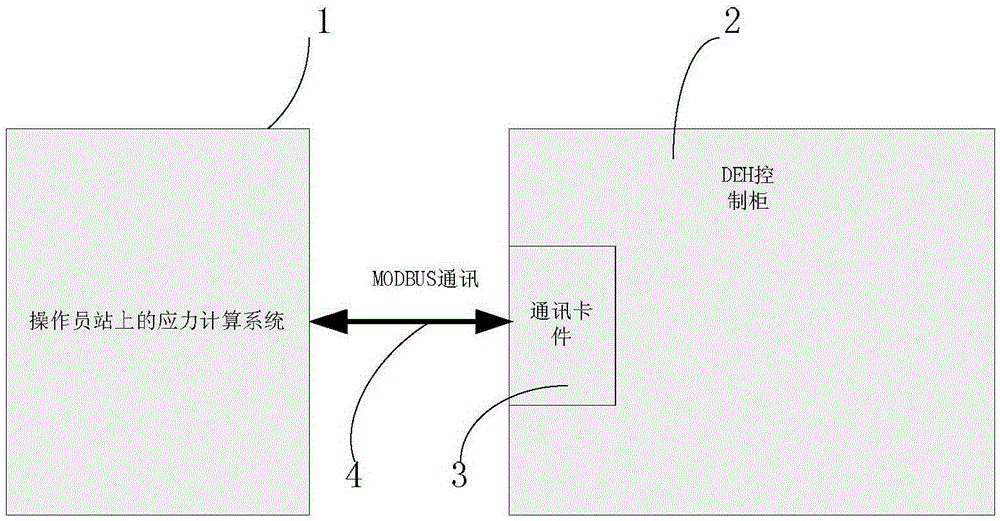

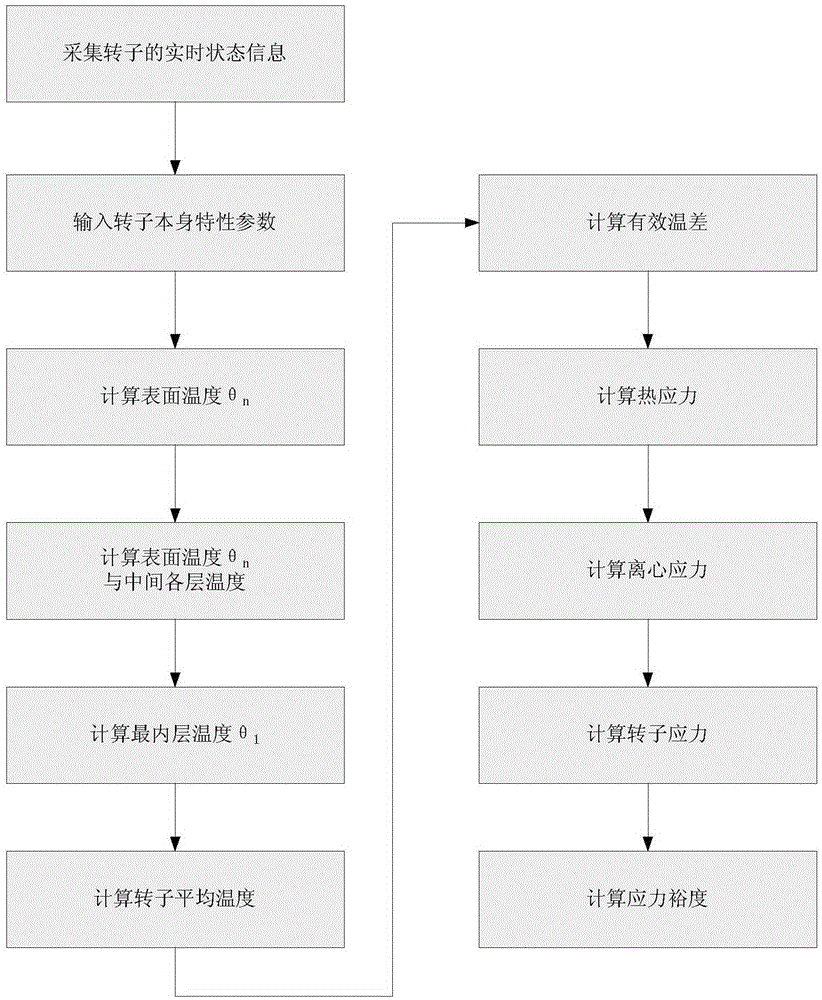

[0027] Specific implementation mode one: combine figure 1 , Figure 5 The steam turbine rotor stress online real-time monitoring system described in this embodiment includes: a modbus for reading the real-time state information of the rotor from the DEH control cabinet (2), and transmitting data to the DEH control cabinet (2) through the communication card (3) communication module;

[0028] A parameter display module for displaying the real-time status information of the rotor and the characteristic parameters of the rotor itself;

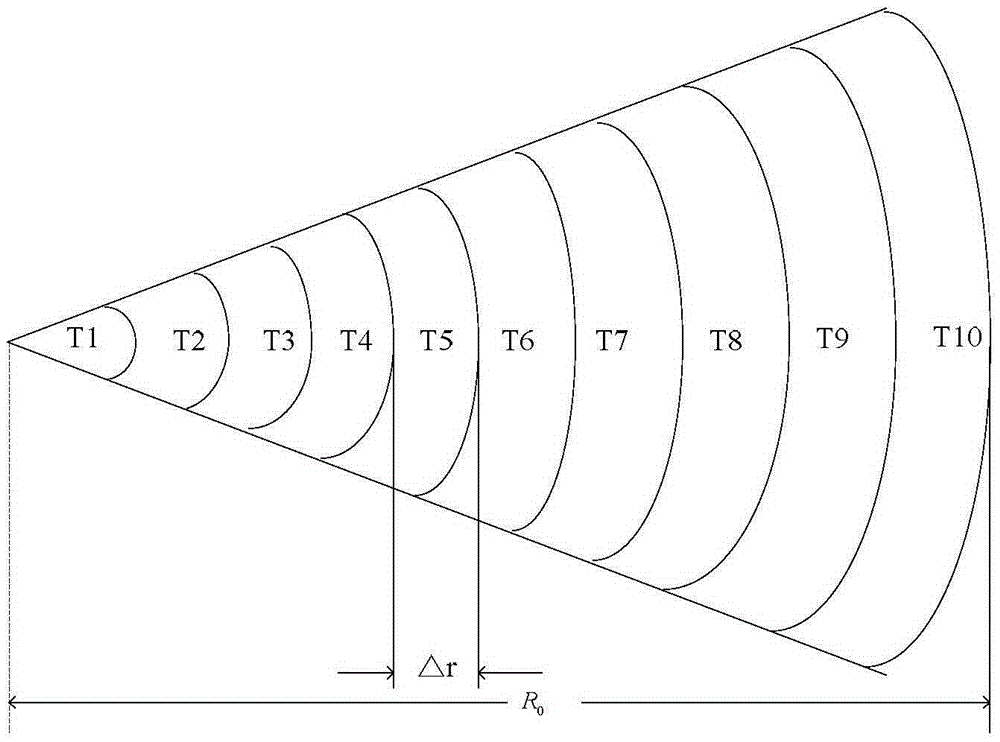

[0029] The rotor temperature calculation and display module is used to calculate the layer temperature, average temperature and effective temperature difference of each layer of the rotor, and display it in the corresponding window in the form of a bar graph and a curve;

[0030] A rotor stress calculation display module for calculating the stress of the rotor at each moment and displaying the rotor stress curve at each moment in the correspondin...

specific Embodiment approach 2

[0039] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the real-time status information includes the rotational speed N 1 , after adjusting the metal temperature θ 0 , steam temperature θ after regulating stage ∞ , Regulating stage pressure P.

specific Embodiment approach 3

[0040] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the characteristic parameters of the rotor itself include Poisson’s ratio u, rotor radius R 0 , rotor thermal conductivity λ, linear expansion coefficient β, elastic modulus E, stress concentration coefficient K th , rotor specific heat c, allowable stress σ 许用 , rotor density ρ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com