Anti-corrosion welding rod for constructing cargo-oil tanks of tank ships

A cargo oil tank and welding rod technology, applied in welding media, manufacturing tools, welding equipment, etc., can solve the problem that the requirements of corrosion-resistant steel cannot be met, the welding rod is not suitable for the welding of oil tanker cargo oil tanks, and the corrosion resistance of corrosion-resistant steel varies greatly. And other issues

Inactive Publication Date: 2012-11-28

CENT IRON & STEEL RES INST

View PDF9 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The corrosion resistance of the shipbuilding welding rod produced by the existing technology is quite different from that of the newly developed corrosion-resistant steel, which cannot meet the requirements of the corrosion-resistant steel

The low-alloy steel corrosion-resistant electrodes used in other fields are mainly aimed at atmospheric corrosion environment or seawater corrosion environment, which is very different from the corrosion environment of oil tanker cargo tanks. These electrodes are not suitable for welding of oil tanker cargo tanks.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an anti-corrosion welding rod for constructing tcargo-oil tanks of tank ships, belonging to the technical field of welding. Deposited metal of the welding rod comprises the following components in mass percentage: 0.03-0.15% of C, 0.05-1.0% of Si, 0.1-2.0% of Mn, less than or equal to 0.025% of P, less than or equal to 0.012% of S, 0.05-1.5% of Ni, 0.05-1.0% of Cu, 0.005-0.5% of Ti, greater than or equal to 0% and less than or equal to 1.0% of Cr, greater than or equal to 0% and less than or equal to 1.0% of Mo, greater than or equal to 0% and less than or equal to 1.0% of W, greater than or equal to 0% and less than or equal to 0.1% of B, greater than or equal to 0% and less than or equal to 0.1% of RE, greater than or equal to 0% and less than or equal to 0.1% of A1 and the balance of iron and other avoidable impurities. According to requirements, the deposited metal of the welding rod also can comprise at least one of the following components in mass percentage: greater than or equal to 0% and less than or equal to 0.3% of Sb, greater than or equal to 0% and less than or equal to 0.3% of Sn, greater than or equal to 0% and less than or equal to 0.3% of As, greater than or equal to 0% and less than or equal to 0.3% of Se and greater than or equal to 0% and less than or equal to 0.3% of Pb. The anti-corrosion welding rod for constructing cargo-oil tanks of tank ships has the advantages that: the component design of the deposited metal of the welding rod is reasonable and the welding lines after the welding have favorable uniform corrosion resistance and spot corrosion resistance without anti-corrosion treatment so that the corrosion resistance of whole tank ships can be improved.

Description

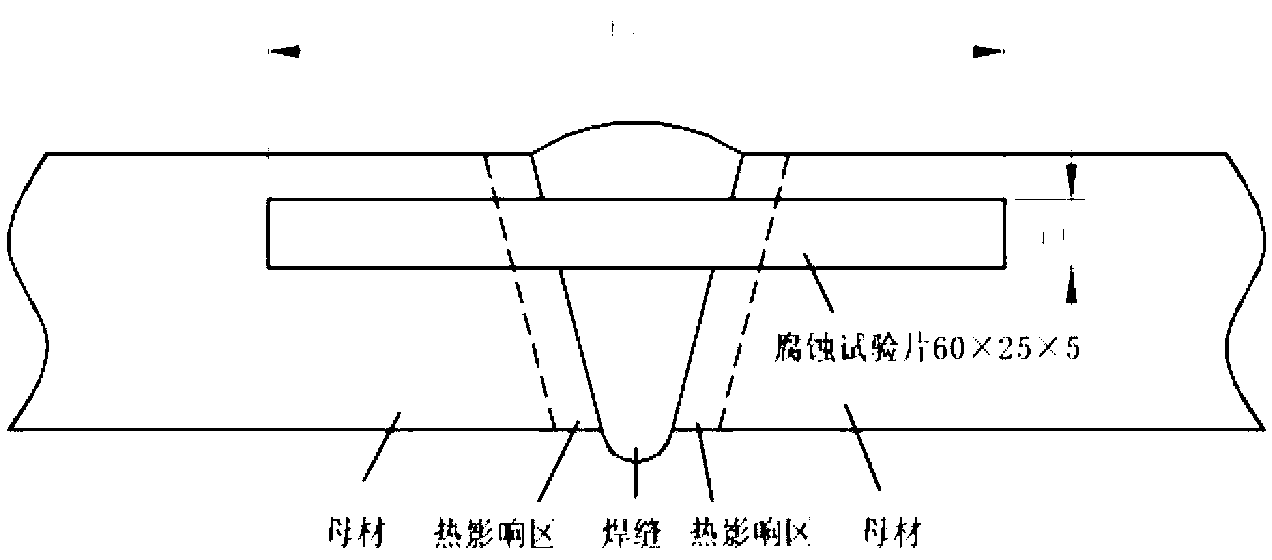

technical field [0001] The invention belongs to the field of welding technology, and in particular relates to a corrosion-resistant welding rod used in the construction of cargo oil tanks of oil tankers. Pitting performance. Background technique [0002] When the cargo oil tank of an oil tanker is filled with crude oil, the cargo oil tank is in an extremely complex and harsh corrosive environment. The first is uniform corrosion on the inner and upper decks of cargo oil tanks. During the transportation of crude oil, the cargo oil tank is filled with explosion-proof gas (5% O 2 +13%CO 2 +0.01%SO 2 +0.1%H 2 S+bal N 2 ), under the alternation of day and night, the temperature and humidity in the cargo oil tank of the tanker change, and water droplets will condense on the upper deck. Due to the presence of acidic gas in the cargo oil tank, the PH value in the water droplets is relatively low. This acidic water corrodes the deck to form rust, and the formed rust will act as...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K35/30

Inventor 齐彦昌彭云田志凌马成勇肖红军魏金山何长红张晓牧杨柏

Owner CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com