Flux-cored wire for cargo oil tank of oil tanker

A technology of flux-cored welding wire and cargo oil tank, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., and can solve problems such as corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

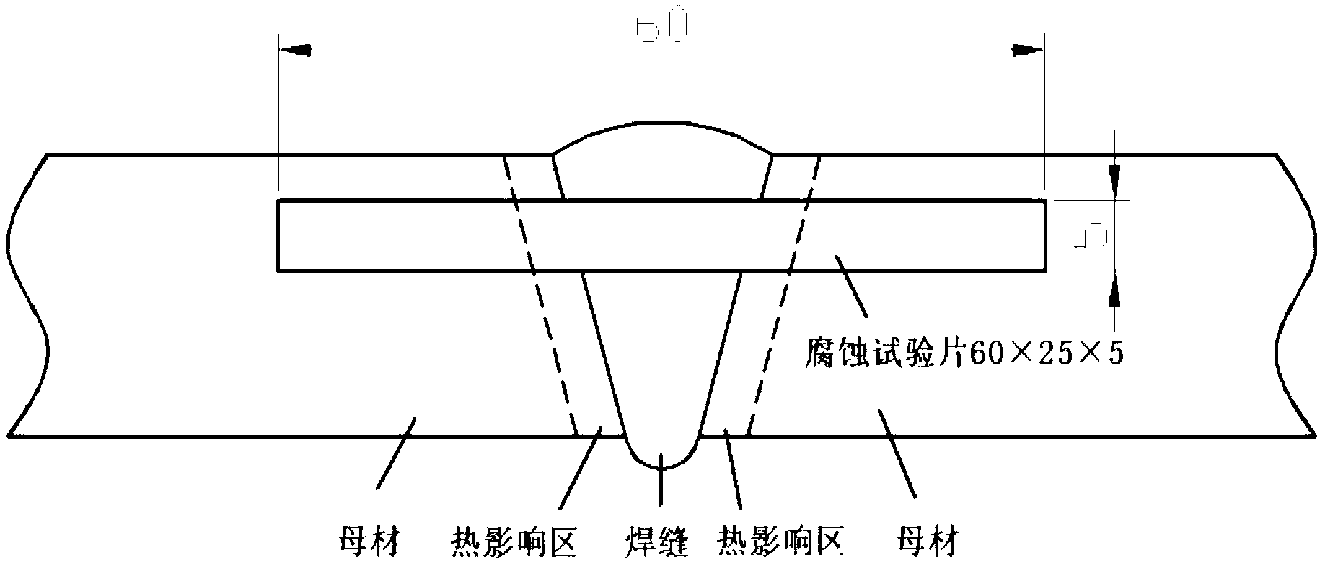

Image

Examples

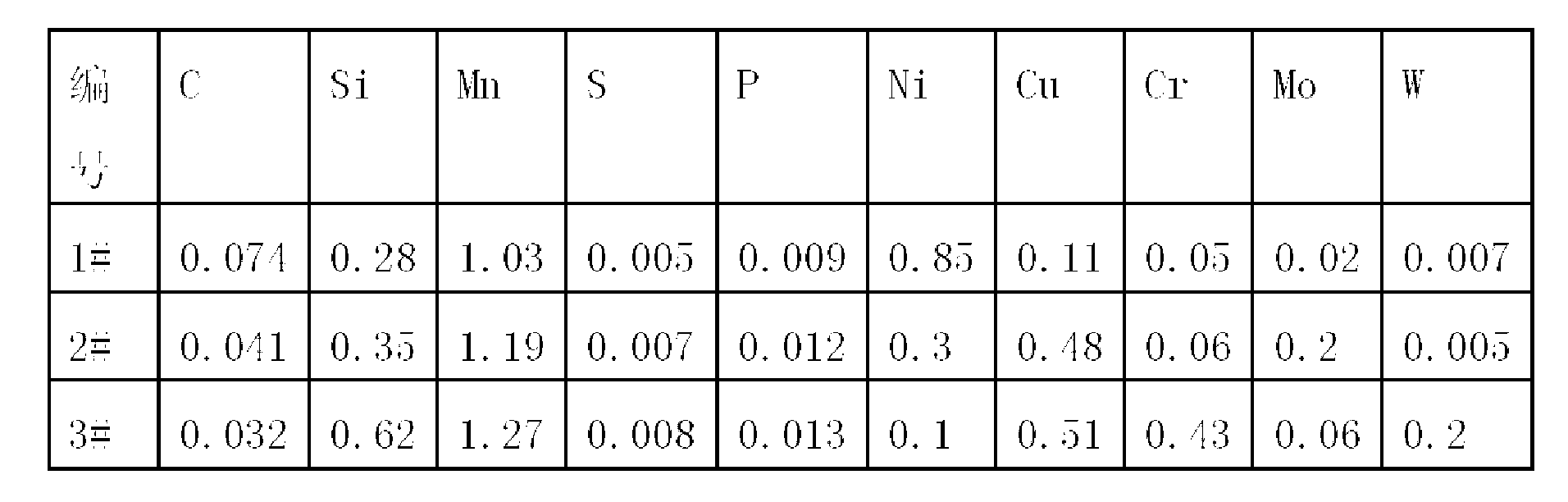

Embodiment

[0026] Using alkaline powder, the powder contains SiO 2 :8.2%, Al 2 o 3 : 0.5%, CaO: 3.6%, K 2 O: 0.6%, CO 2 : 2.7%, C: 1.2%, Mn: 6.2%, CaF2: 23.1%, the balance is iron and unavoidable impurities, all are percentages by mass; the wire sheath is carbon steel strip.

[0027] Example: 2

[0028] Titanium-calcium powder is used, and the powder contains SiO 2 : 19.8%, Al 2 o 3 : 1.97%, TiO 2 : 36.7%, CaO: 1.1%, Na 2 O: 1.7%, K 2 O: 1.4%, CO 2 : 0.6%, C: 0.7%, Mn: 14.7%, the balance is iron and unavoidable impurities, all are percentages by mass; the wire sheath is carbon steel strip.

[0029] Example: 3

[0030] Titanium-type powder is used, and the powder contains SiO 2 : 21.7%, Al 2 o 3 : 2.4%, TiO 2 : 39.5%, Na 2 O: 1.5%, K 2 O: 1.3%, CO 2 : 0.5%, C: 0.6%, Fe: 17.4%, Mn: 15.1%, the balance is iron and unavoidable impurities, all are percentages by mass; the wire sheath is carbon steel strip.

[0031] The deposited metal test is carried out with reference to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com