Method for Improving the Uniformity of Corrosion Amount in Each Track of Texturing or Wet Etching Equipment

A technology of wet etching and corrosion amount, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve the problems of uneven corrosion amount of each track in texturing and wet etching, and avoid additional costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

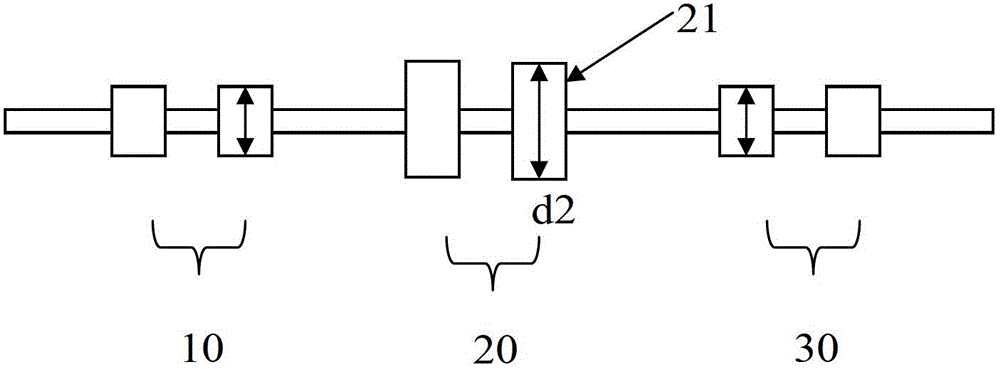

[0014] According to a typical implementation of the present invention, the method for improving the uniformity of the corrosion amount of each track of the texturing or wet etching equipment includes the following steps: 1) detecting the corrosion amount of the silicon wafer in each track; 2) adjusting the corrosion amount to be too large or The diameter of the guide wheel on the smaller track can increase or decrease the corrosion amount of the silicon wafer by controlling the depth of the silicon wafer on the guide wheel entering each track in the equipment, and finally make the corrosion amount of the silicon wafer in each channel consistent. As shown in Figure 1, the track 10, the track 20 and the track 30 are part of the track of the texturing or wet etching equipment, for example, the diameter d2 of the guide wheel 21 can be adjusted according to actual needs, so as to achieve the adjustment of the corrosion amount is too large or The small problem keeps the corrosion amo...

Embodiment

[0018] 1. Adjust the parameters of 8 tracks: the exhaust air volume is 35~45m 3 / h, the liquid contains HNO with a mass percentage of 45~60% 3 , the mass percentage is 2~4% HF solution; the temperature is 10~18°C; the transmission speed is 1.2~2.0m / min;

[0019] 2. Detect the corrosion amount of silicon wafers in each track: by testing the weight of silicon wafers before and after corrosion, the corrosion depth of silicon wafers is calculated according to the weight difference through the area and density, and the corrosion depth of each track is calculated by weighing: track Track 1 is 1.3 μm, track 2 is 3.6 μm; track 3 is 3.4 μm; track 4 is 3.5 μm; track 5 is 3.4 μm; track 6 is 3.6 μm; track 7 is 3.5 μm; track 8 is 3.4 μm;

[0020] 3. Adjust the guide wheel diameter of track 1 to reduce by 1~2mm;

[0021] 4. The corrosion amount of the silicon wafer in each track was detected again, and the result showed that the corrosion depth of track 1 became 3.5 μm.

[0022] From the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com